Design and Prototype Mold of Carbon Composite Electrode for

Synthesis Graphene with Electrochemical Exfoliation Method

Isnanda Nuriskasari, Agus Edy Pramono, Hamdi and Dendy Arista

Mechanical Engineering, Politeknik Negeri Jakarta, Jl. Prof. G. A. Siwabessy, Depok, Indonesia

Keywords: Graphene, Electrode, Mold, Carbon Composite, Electrochemical Exfoliation.

Abstract: Graphene is a new material that has special electrical, thermal, magnetic, optical, mechanical and chemical

properties. The method for synthesis graphene that is currently being developed is through the electrochemical

exfoliation because it has the advantages of a fast, environmentally friendly manufacturing process, and low

costs in the production process, and the resulting low defect value of the graphene material. One of the most

important component for syhnthesis graphene with this method is electrodes. Electrodes at this method act as

a source of carbon for synthesis graphene. Most of the researcher use graphite (sheet, rod, and flakes) as a

electrodes for this method. This research aims to synthesis graphene with electrochemical exfoliation with

carbon composite as a electrode. This paper is the first stage at this research to design and create a mold of

carbon composite electrode. The result of the first stage of this research is using material ST 37 that have

thick 5mm to create mold of carbon composite electrode, the shapes of this electrodes is block with dimension

15 x 1 x1 [cm].

1 INTRODUCTION

The advantages of graphene material properties

because of it is a thin sheet (nanoparticle scale), but

have high strength and electrical and thermal

conductivity. The thermal conductivity of graphene is

five times greater than copper, but the weight of the

graphene material is four times lower than copper and

the electrical conductivity of graphene is equivalent

to copper. Graphene has a lower density than steel,

but the strength of graphene can reach up to fifty

times that of steel. In addition, graphene has a very

high surface area of up to 2,500 m

2

/ g (Liu et al.,

2019). Therefore, many researcher have research on

graphene materials for application in the energy

sector, one of which is to store energy such as

batteries, solar cells and supercapacitors.

Nowdays, a graphene synthesis method that is

more environmentally friendly is being developed,

namely the electrochemical exfoliation method. The

electrochemical exfoliation method has advantages in

terms of a fast, environmentally friendly, and low cost

manufacturing process in the production process

(Ramadhan et al., 2019). This method produces

graphene flakes that have a smaller defect value

because the electrochemical removal of the graphite

layer requires a lower agitation intensity to disperse

the graphene compared to other liquid phase methods

(Mir & Shukla, 2018). The synthesis of graphene with

the electrochemical exfoliation method requires 3

components, there are an electrolyte solution, an

electrode as well as a carbon source, and an electric

current.

One of the most important component for

synthesis graphene with electrochemical exfoliation

method is electrodes. This research aims to synthesis

graphene with electrochemical exfoliation with

carbon composite electrode. (Pramono et al., 2012)

have researched on the electrical conductivity of

carbon-carbon composites from coal tar and coconut

shell waste. The results showed that the increase in

density of the carbon-carbon composite material had

an effect on the increase in the conductivity of the

electrical material.

Based on those explanation, in this paper, the

research focuses on design and create a mold of

carbon composite electrode. The shapes of electrodes

that will use for synthesis graphene is a block with

dimension 15 x 1 x1 [cm]. This research will also tests

on the molds that have been created to produce carbon

composite electrodes for graphene synthesis, then the

electrodes will be tested on initial test for act as a

source of carbon to synthesis graphene with

electrochemical exfoliation method.

Nuriskasari, I., Pramono, A., Hamdi, . and Arista, D.

Design and Prototype Mold of Carbon Composite Electrode for Synthesis Graphene with Electrochemical Exfoliation Method.

DOI: 10.5220/0010508200003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 13-17

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

13

2 RESEARCH METHOD

This research begin by design the mold of carbon

composite electrode that will produce electrode with

block shapes 15 x 1 x1 [cm]. One of the most

important things to design this mold is procedures to

produce this carbon composite electrode. Refer to

(Pramono et al., 2012), procedures to produce carbon

composites electrode are :

1. Prepare the basic material of carbon 300 mesh and

tar with a ratio of 5: 7

2. Melt the tar for the first before mixture with 300

mesh of carbon, and then mix the tar that has been

melted with 300 mesh of carbon.

3. Put the mixture into the mold of carbon composite

electrode, and giving the pressure at 200 bar.

4. The carbon-carbon composite mixture at the mold

of electrode was heating/curing at a temperature of

200

0

C.

5. Furthermore, the carbon composite electrode is

remove from the mold. To optimize the electrical

conductivity of the electrodes, a re-curing process

was carried out without mold at a temperature 950

0

C.

Based on those explanation about procedure to

produce carbon composite electrode, we must create

the mold of carbon composite electrode that have

specification to easy remove the carbon composite

electrode after curing 200

0

C. On the other side, the

material for the mold must good in mechanical and

thermal properties, such as have a good strength,

good a conductivity thermal, and good a resistant

corrosion, because the mold will be pressed at 200 bar

and curing at 200

0

C. ST 37 with the thick 5 mm is the

best material for this mold. Table 1 showed the

mechanical properties of ST 37 and Table 2 showed

the chemical composition of ST 37.

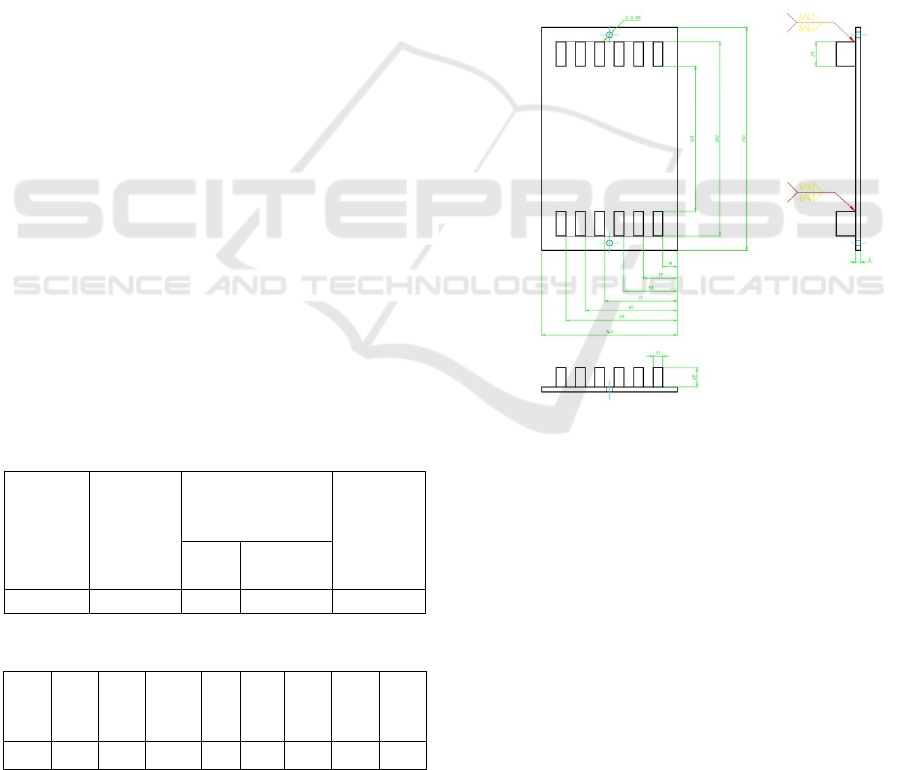

Table 1 Mechanical Properties of ST.37

Grade Tensile

strength

(Mpa)

Yield strength

(Mpa) not less

than

Elongati

on (%)

not less

than

= 16

mm

>16 mm

St37 350-480 235 225 25

Table 2 Chemical Composition of ST 37

Gr

ad

e

C Si Mn P S Cr Ni Cu

St37 0.17 0.17-

0.37

0.35-

0.65

0.0

25

0.02 0.25 0.25 0.25

3 RESULTS AND DISCUSSION

To create the mold of carbon composite electrode that

have specification easy to remove the electrode after

curing at 200

0

C and produce the carbon composite

electrodes that have a good conductivity, design the

mold is important thing for the first step. Figure 1

showed the design for the part of the base of the mold.

The design for this mold is to produce 4 electrodes

that each electrode have dimension 15 x 1x 1 [cm].

The method to create this part is by the welding the

material ST 37 refer to the design. The mold have

length and width 230 x 140 [mm]. There is a part like

a fin at the mold base that act as a holder with

dimension 10 x 20 [mm], this part will be welded on

the mold base. The number of fins on the one of the

side at the mold base is 6, the distance between the

fins is 10 mm.

Figure 1: Part of the Mold base

Figure 2 showed the design for part of the mold

base that act as a holder that will put into the part

between the fins, this material is amuntit. This part is

not welded to the mold base because of the molding

must have spesification easy to remove the electrodes

after the curing at 200

0

C. The dimension of this part

is 200 x 10 x 20 [mm].

ASAIS 2020 - Annual Southeast Asian International Seminar

14

Figure 2: Holder of the Mold Base

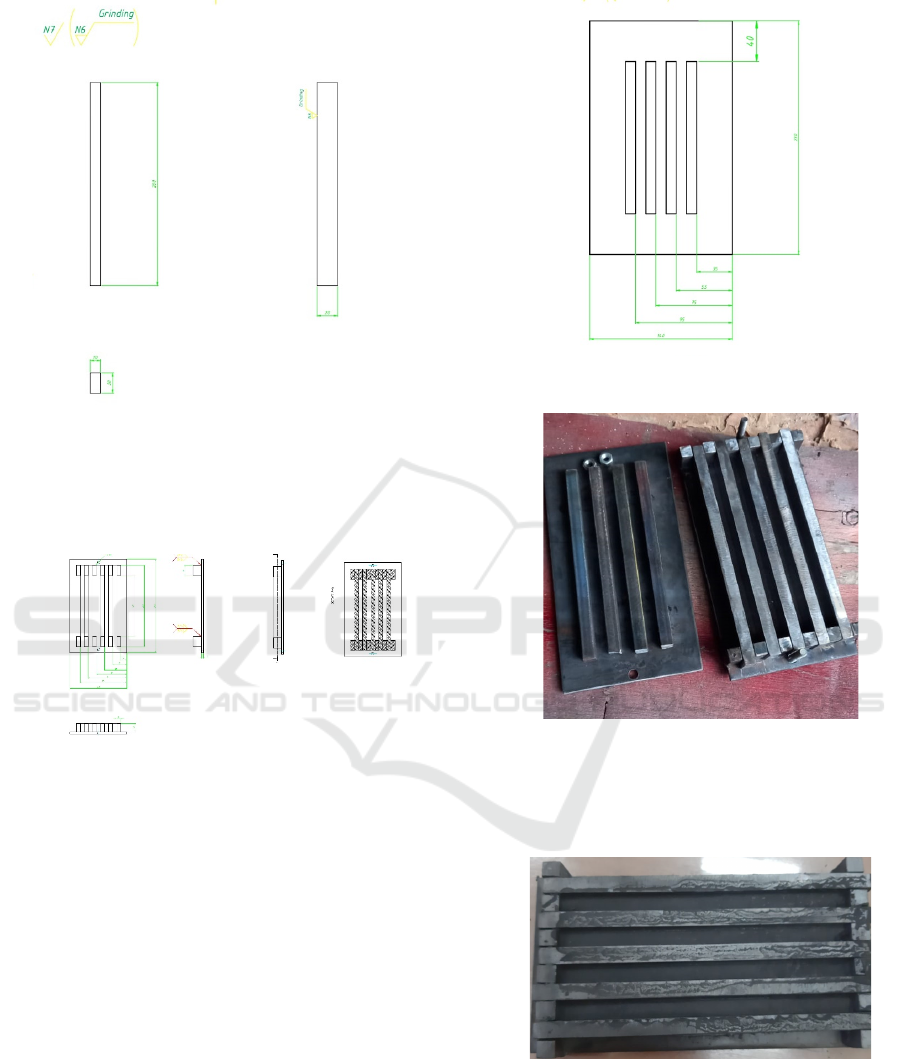

Figure 3 showed the final mold base of carbon

composite electrode that will produce 4 electrodes,

combination figure 3 and 4.

Figure 3: Mold Base of Carbon Composite Electrode

Figure 4 showed the design for the mold top that

have part to press the material electrode. The material

for this part is ST 37, same to the material for the

mold base. The method to create this part is by the

welding the material ST 37 refer to the design. The

length and width of the mold top is 230 x 140 [mm],

there are 4 parts that act as a press the material

electrode. The dimension for this part is 150 x 10 x 5

[mm]. The final result of the mold of carbon

composite electrode can be seen at figure 5.

Figure 4: Mold Top of Carbon Composite Electrode

Figure 5: Mold of Carbon Composite Electrode

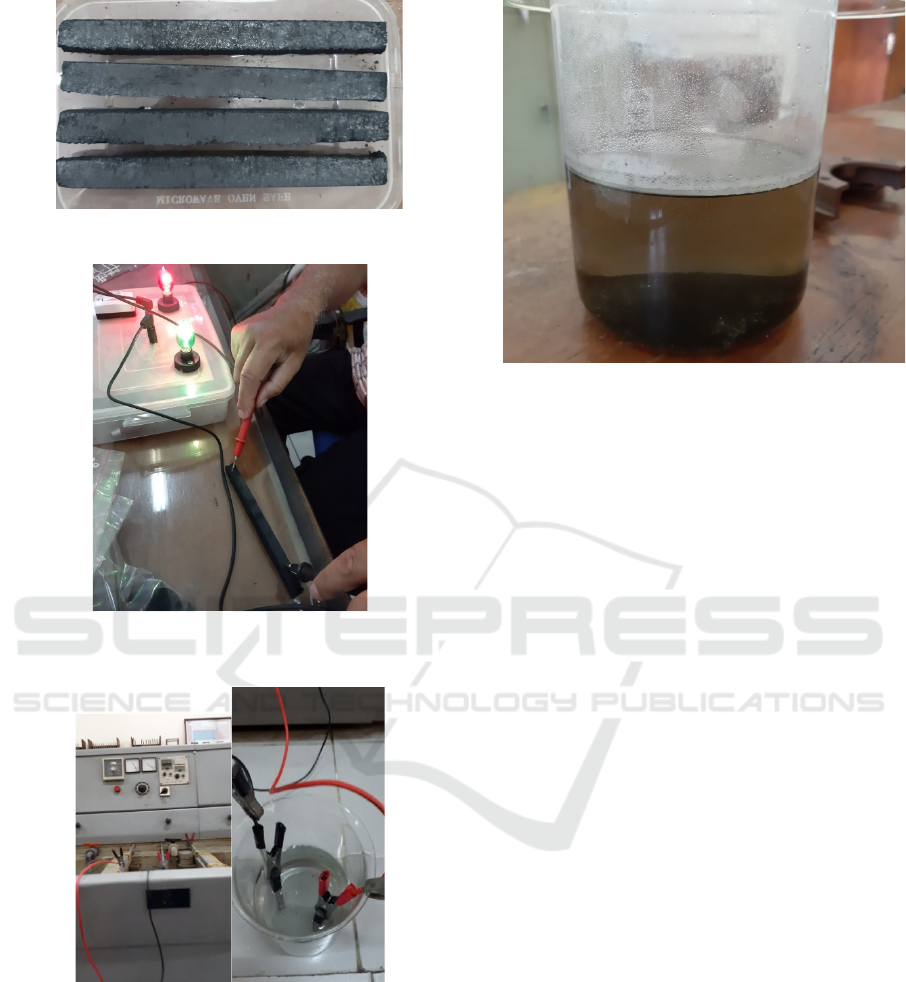

After that, the mold will be tested to produce

electrodes from carbon composite that can be seen on

figure 6 and figure 7.

Figure 6: Carbon Composite Electrode at The Mold

Design and Prototype Mold of Carbon Composite Electrode for Synthesis Graphene with Electrochemical Exfoliation Method

15

Figure 7: Carbon Composite Electrodes

Figure 8: Conductivity Test for The Carbon Composite

Electrode

Figure 9: Electrochemical Exfoliation with Carbon

Composite Electrodes

Figure 10: The Result of Electrochemical Exfoliation with

Carbon Composite Electrodes

Figure 8 show the result of the conductivity test

carbon composite electrode that can turn on the lamp,

so this electrode have electrical conductivity. The

result of initial test that using carbon composite

electrode for synthesis graphene with electrochemical

exfoliation method can be seen at figure 9 and figure

10. It was proven that the carbon-carbon composite

made of coconut shell and tar was successful in acting

as anode and cathode, and the exfoliating carbon layer

on the anode and cathode succeeded in forming

graphene.

4 CONCLUSION

Mold of the composites carbon electrode can be made

from material ST 37 which have thick 5 mm. The

mold prove can produce 4 electrodes, each electrode

have dimension 15x1x1 [cm]. The carbon-carbon

composite made of coconut shell and tar was

successful in acting as anode and cathode, and the

exfoliating carbon layer on the anode and cathode

succeeded in forming graphene.

REFERENCES

Ghorbani, M., Abdizadeh, H., & Golobostanfard, M. R.

(2015). Reduction of Graphene Oxide via Modified

Hydrothermal Method. Procedia Materials Science,

11(2009), 326–330.

https://doi.org/10.1016/j.mspro.2015.11.104

Inagaki, M., Kang, F., Toyoda, M., & Konno, H. (2013).

Advanced Materials Science and Engineering of

Carbon. In Advanced Materials Science and

ASAIS 2020 - Annual Southeast Asian International Seminar

16

Engineering of Carbon. https://doi.org/10.1016/C2012-

0-03601-0

Khadifah, Filla Mulyawati. (2017). Sintesis Graphene

Berbasis Arang Tempurung Kelapa dengan Metode

Hummers Termodifikasi. Surabaya : Institut Teknologi

Sepuluh Nopember., 1-56

Liu, F., Wang, C., Sui, X., Riaz, M. A., Xu, M., Wei, L., &

Chen, Y. (2019). Synthesis of graphene materials by

electrochemical exfoliation: Recent progress and future

potential. Carbon Energy, 1(2), 173–199.

https://doi.org/10.1002/cey2.14

Mir, A., & Shukla, A. (2018). Electrochemical exfoliation

of graphite to stage-III graphite bisulfate flakes in low

concentration sulfuric acid solution: A novel synthesis

route to completely trilayer graphene suspension.

Applied Surface Science, 443, 157–166.

https://doi.org/10.1016/j.apsusc.2018.02.284

Pramono, A. E., Zulfia, A., & Soedarsono, J. W. (2011).

Physical and Mechanical Properties of Carbon-Carbon

Composite Based Coconut Shell Waste. Journal of

Materials Science and Engineering, 5(October 2014),

12–19.

Pramono, A. E., Zulfia, A., & Soedarsono, J. W. (2012).

Effect of the Density to the Electrical Conductivity of

Carbon-Carbon Composite Made of the Mixture of

Organic Waste Carbon. Journal of Materials Science

and Engineering A, 2(5), 402–409.

Ramadhan, D. A., Kurniawan, C., & Mahatmanti, F. W.

(2019). Indonesian Journal of Chemical Science

Pengelupasan Lapisan Grafit secara Elektrokimia

dalam Suasana Asam. 8(2), 6.

Resmi, P. E., Palaniayappan, A. L., Ramachandran, T., &

Babu, T. G. S. (2018). Electrochemical synthesis of

graphene and its application in electrochemical sensing

of glucose. Materials Today: Proceedings, 5(8),

16487–16493.

https://doi.org/10.1016/j.matpr.2018.06.001

Singh, R., & Charu Tripathi, C. (2018). Electrochemical

Exfoliation of Graphite into Graphene for Flexible

Supercapacitor Application. Materials Today:

Proceedings, 5(1), 1125–1130.

https://doi.org/10.1016/j.matpr.2017.11.192

Sohail, M., Saleem, M., Ullah, S., Saeed, N., Afridi, A.,

Khan, M., & Arif, M. (2017). Modified and improved

Hummer’s synthesis of graphene oxide for capacitors

applications. Modern Electronic Materials, 3(3), 110–

116. https://doi.org/10.1016/j.moem.2017.07.002

Design and Prototype Mold of Carbon Composite Electrode for Synthesis Graphene with Electrochemical Exfoliation Method

17