Lignin Isolation from Oil Palm Empty Fruit

Bunches (OPEFB) by Acidic Method

Saharman Gea

1*

, Amir Hamzah Siregar

2

, Emma Zaidar

2

, Mahyuni Harahap

2

, Yurika Almanda

Perangin-Angin

2

1

Cellulosic and Functional Materials Research Centre Universitas Sumatera Utara, Jalan Bioteknologi Medan, Indonesia

20155

2

Chemistry Department Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Jalan Bioteknologi,

Medan, Indonesia 20155

Keywords: Oil palm empty fruit bunches, Lignin, FTIR, UV-visible

Abstract: The isolation of lignin from oil palm empty fruit bunches (OPEFB) has been done. Firstly, OPEFB was

immersed in NaOH 2% and 4%. Then, the filtrate was acidified by using H

2

SO

4

5N to obtain the lignin.

SEM morphology of isolated lignin showed rough surfaces. While, chemical structures of the lignin were

analyzed by using FTIR and UV-visible. Aromatic ring vibrations of the phenylpropene (C9) skeleton

appeared at 1600 cm

-1

, 1515 cm

-1

, and 1425 cm

-1

. In addition, the presence of aromatic rings/non-

conjugated phenolic groups in lignin structure was observed at 280 nm absorption.

1 INTRODUCTION

Biomass is the most abundant natural bioresources in

the world. It is known as lignocellulosic material as it

consists of three main molecules namely cellulose,

hemicellulose, and lignin (Ma’Ruf, Pramudono and

Aryanti, 2017). Oil palm empty fruit bunches

(OPEFB) are composed of cellulose (41.3-46.5%),

hemicellulose (25.3-32.5%), and lignin (27.6-32.5%).

OPEFB have been reported for their uses in pulp

production, fertilizers for oil palm plantations, carbon

fibre precursors, and electrospun nanocomposite (Gea

et al., 2020)(Misran et al., 2020). However, the

isolation of lignin from OPEFB is still limited.

Lignin has several functional groups such as

methoxy, carbonyl, carboxyl, and hydroxyl (phenolic

and alcoholic components). The chemical structure of

lignin is presented in Figure 1. The phenolic

compounds in lignin can potentially be used as

macromolecular in toughening agents for epoxy resin,

surfactant, and carbon fibre precursors. Lignin-based

carbon fibre is known to have tensile strength and

modulus of 0.51 GPa and 28.6 GPa respectively

(Baker, Gallego and Baker, 2011).

There are several methods to isolate lignin from

biomass, such as using acid and alkali solvent, ionic

solution

and organic solvent, and alkaline hydrogen

Figure 1. The potential chemical structure of lignin

(Gregory, 2007)

Gea, S., Siregar, A., Zaidar, E., Harahap, M. and Perangin-Angin, Y.

Lignin Isolation from Oil Palm Empty Fruit Bunches (OPEFB) by Acidic Method.

DOI: 10.5220/0010613900002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 581-583

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

581

peroxide (H

2

O

2

) (Ma’Ruf, Pramudono and Aryanti,

2017). The isolation of lignin using acid solvent

method has some advantages, such as low-cost,

efficient production, and low temperature

requirement.

In this study, we extracted lignin from OPEFB

using H

2

SO

4

at room temperature. The isolated

lignin was characterized for its morphology and

chemical structures.

2 EXPERIMENTAL

2.1 Materials

Oil palm empty fruit bunches (OPEFB) were

obtained from PTPN IV Adolina, North Sumatera.

NaOH

(s)

and H

2

SO

4(l)

97% were purchased from

Merck, Germany.

2.2 Isolation and Purification of Lignin

The fibres of OPEFB were immersed in different

concentration of NaOH, such as 2% and 4%. The

immersion process was done at room temperature for

24 h. After that, OPEFB were filtered and acidified

by using 5 N H

2

SO

4

to reach pH 2. The acidified

solution was washed with distilled water and filtered.

The solid parts were collected and centrifuged at

8000 rpm for 5 min. Finally, the isolated lignin was

dried in a vacuum oven at 50

o

C for 4 h. The

products were coded as lignin2% and lignin4%.

2.3 Characterization

2.3.1 FTIR

The functional groups in isolated lignin were

investigated by using FTIR Spectrometer (FTIR,

Nicolet 380, Thermo Scientific, Boston, MA, USA).

The sample was analyzed in a disk form with 100:1

KBr to sample ratio. FTIR instrument was operated

in transmission mode with 400–4000 cm-1

wavelengths, 4 cm-1 resolution, and 100 scans.

2.3.2 UV-Visible

The aromatic rings in lignin were investigated by

using ultraviolet/visible spectrophotometer (UV

1800 series, Shimadzu Scientific Instrument, Kyoto,

Japan). The instrument was operated with

absorbance between 250 and 400 nm wavelengths.

2.3.3 Scanning Electron Microscopy

Sample morphology was analyzed by using Scanning

Electron Microscopy (SEM, Hitachi TM3030, JEOL,

Ltd., Tokyo, Japan) operating at 20 kV. The sample

was first coated with a thin layer of gold before

analysis to reduce charges.

3 RESULTS AND DISCUSSION

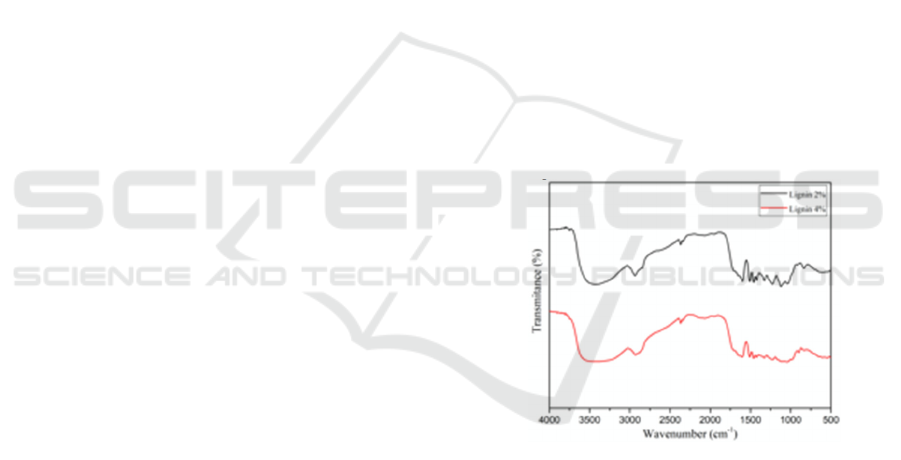

3.1 FTIR Analysis

The functional groups present in the isolated lignin

were analyzed by using FTIR spectral analysis. FTIR

spectra for the polymers are presented in Figure 2.

Aromatic ring vibrations of the phenylpropene (C9)

skeleton could be seen to have appeared at 1600 cm

-

1

, 1515 cm

-1

, and 1425 cm

-1

. The absorption between

3600 and 300 cm

-1

was attributed to hydroxyl groups

in the aromatic and aliphatic structures. In addition,

C-H stretching in methyl and methylene groups, as

well as C-H stretching in aromatic methoxy group

were observed at 2938 cm

-1

and 2885 cm

-1

respectively (Chen et al., 2016; Abdelaziz and

Hulteberg, 2017).

Figure 2 FTIR spectra of isolated lignin immersed in

NaOH 2% and NaOH 4%.

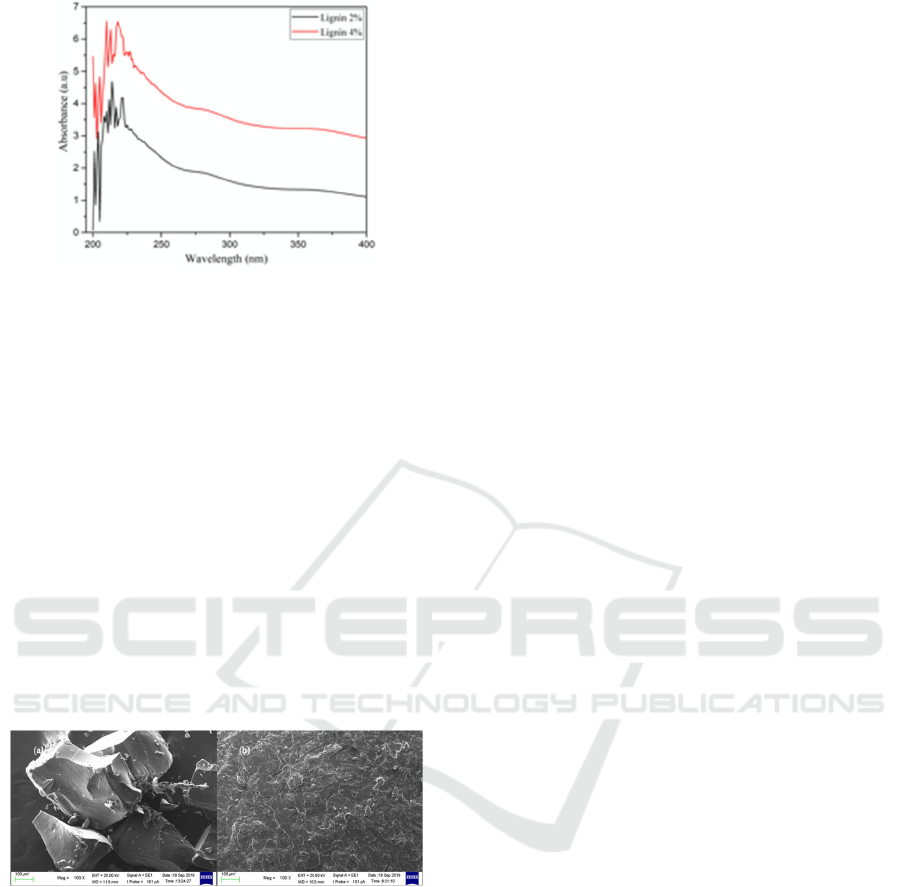

3.2 UV-visible Analysis

UV-visible analysis (Figure 3) was used to

investigate the presence of aromatic rings/non-

conjugated phenolic groups in the structures of

lignin. From Figure 3, there was an absorption at

approximately 280 nm, which indicated aromatic

rings in lignin (Gea et al., 2020).

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

582

Figure 3. UV-visible of lignin immersed in NaOH 2% and

NaOH 4%.

3.3 Scanning Slectron Microscopy

Morphology

Surface morphology of isolated lignin is shown in

Figure 4. Before analysis, isolated lignin was dried at

80

o

C for 5 h in a vacuum oven to remove moisture

and water content. Then, the sample was coated with

a thin gold to reduce charging during analysis. As

seen in Figure 4, the morphology of isolated lignin

was rough and flaky. This finding result was

different by a previous study that reported lignin

with smooth and uniform morphology in powder

form (van de Pas et al., 2011). These different results

could be caused by different instrument and isolation

procedure used. Furthermore, NaOH 4% produced a

smoother surface morphology than NaOH 2%.

Figure 4. Surface morphology of isolated lignin immersed

in (a) NaOH 2% and (b) NaOH 4%, with magnification of

100x

4 CONCLUSIONS

The isolation of lignin from OPEFB was done by

using acidic solvent (H

2

SO

4

). OPEFB were

immersed in NaOH 2% and 4% before lignin

extraction. FTIR and UV-visible analysis showed

that lignin had aromatic structures. Meanwhile, SEM

analysis confirmed that lignin had rough surface

morphology.

ACKNOWLEDGEMENT

This research was funded by the Indonesian Ministry

of Research and Technology for the supports funds

from DRPM 2019 PDUPT scheme with contract

number 159/UNS.2.3.1/PPM/KP-DRPM/2019.

REFERENCES

Abdelaziz, O.Y., Hulteberg, C. P. 2017. Physicochemical

characterisation of technical lignins for their potential

valorisation, Waste and Biomass Valorization.

Springer Netherlands, 8(3), pp. 859–869. doi:

10.1007/s12649-016-9643-9.

Baker, D. A., Gallego, N. C. and Baker, F. S. 2011 On the

characterization and spinning of an organic- purified

lignin toward the manufacture of low-cost carbon

fiber. doi: 10.1002/app.

Chen, J., Liu C., Wu S., Liang J., Lei M. 2016. Enhancing

the quality of bio-oil from catalytic pyrolysis of kraft

black liquor lignin’, RSC Advances. Royal Society of

Chemistry, 6(109), pp. 107970–107976. doi:

10.1039/c6ra18923g.

Gea, S. Siregar A.H., Zaidar E., Harahap M. 2020.

Isolation and characterisation of cellulose nanofibre

and lignin from oil palm empty fruit bunches’,

Materials, 13(10).

Gregory, A. P. (2007) Green chemistry. Available at:

tp://www.research.uky. edu/images/lignin.jpg.

Ma’Ruf, A., Pramudono, B., Aryanti, N. 2017. Lignin

isolation process from rice husk by alkaline hydrogen

peroxide: lignin and silica extracted’, AIP Conference

Proceedings, 1823(March). doi: 10.1063/1.4978086.

Misran, E., Wiryosentono B., Noor N.M., Gea S.,

Situmorang S.A., Harahap M. 2020. Preparation and

Characterisation of electrospun composite nanofibre

Pplyvinyl alcohol/ nanofibrillated cellulose isolated

from oil palm empty fruit bunches, BioResources,

15(4), pp. 7906–7917. doi: 10.15376/biores.15.4.7906-

7917.

van de Pas, D., Hickson A., Donadson L., Jones G.L. 2011.

Characterization of fractionated lignins polymerized by

fungal laccases, BioResources, 6(2), pp. 1105–1121.

doi: 10.15376/biores.6.2.1105-1121.

Lignin Isolation from Oil Palm Empty Fruit Bunches (OPEFB) by Acidic Method

583