A MAS Model Approach to a Wind Farm Maintenance Strategy

Miguel Kpakpo, Mhamed Itmi

and Alain Cardon

Normandie Université, INSA, LITIS, France

Keywords: Cost Optimization, Decision Support Systems, Maintenance Strategy, MAS, O&M.

Abstract: The aim of this work is to propose a new method of analysis and optimization of maintenance strategy for

wind farms. The objective is to help wind farm operator to carry out the optimization of the maintenance

costs through profitability analysis of the wind farm according to failures, planned shutdown situations and

maintenance budgets. Such approach has the advantage of combining the O&M (optimization and

maintenance) technical vision and the financial vision within the meaning of profitability. The platform

model is based on multi-agent systems. It aims to realize the calculation and optimization of scenarios.

Agents have been identified from the knowledge of the windfarm O&M domain thanks to the wind farm

operator’s point of view. The platform we’re developing is named PROMEEO, a French acronym for O&M

onshore wind farms rationalization and optimization’s platform.

1 INTRODUCTION

The maintenance of the equipment represents an

important issue in all industries. In wind energy’s

case where the exploitation of the wind farm is

strongly impacted by maintenance policies

management. A wind farm is established for an

approximate lifetime from 20 to 25 years. During

this period, the owner sets up various operations

intended to guarantee the availability of the wind

turbines and their good performance.

For most industrial owners, the optimization of

maintenance is firstly focused on the maintained

equipment (a wind farm for the wind power

operator). Most industrial owners thus focus

themselves on the equipment’s state to maximize its

operating time.

Consequently, the preventive or corrective

policies of maintenance are prioritized to guarantee

the availability of the wind farm, which is the major

indicator of maintenance analysis; it is calculated by

(1):

D % =

Operating time

total time

∗ 100

(1)

The temporal availability allows to know the ratio

corresponding to the operating time of the wind

turbine regarding the total time. It is the ability of an

equipment to be able to perform a given function

under given conditions at a given instant or during a

given interval of time, if the provision of external

means is assured. The percentage of availability

makes it possible to deduct the associated overall

loss of production.

The first objective of the wind farmer is to

maximize availability. Maintenance plays a strategic

role regardless the type of industry. In wind energy

industry, it represents a significant cost; it has a

major impact on the cost of operating the wind

farms. As it has been said, each wind turbine is built

for an approximate service life of 20 to 25 years.

During this period, the operator shall put in place

various maintenance operations to ensure the

availability and operation of the wind turbines. This

availability is determined upstream in the operating

contract. It is located between 80 and 95% according

to farms.

According to the AWE (American Wind

Energy), the cost of O&M is not negligible

throughout the life cycle of a wind farm (Ribrant,

2006). At the end of life, this cost can reach up to

25% of the total cost of kWh. Reducing O&M costs

by 0.18% would result in a 3% reduction in the total

cost of a kWh.

Availability implies a maintenance cost that

cannot be minimized without degrading the

availability rate; then the operators adapt each

maintenance contract to the windfarm’s

characteristics and to the availability objectives

(Piana, 2016). However, the final priority of an

Kpakpo, M., Itmi, M. and Cardon, A.

A MAS Model Approach to a Wind Farm Maintenance Strategy.

DOI: 10.5220/0006554501590167

In Proceedings of the 10th International Conference on Agents and Artificial Intelligence (ICAART 2018) - Volume 1, pages 159-167

ISBN: 978-989-758-275-2

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

159

operator is to opt for the maintenance strategy that

would enable a better profitability of the windfarm.

Our method is focused on this priority. Indeed, the

vision of financial profitability, reinforces the

technical vision of maintenance while usually

profitability is often separated from the financial

sector. Availability is no longer the only criterion of

maintenance analysis because the wind farm’s

profitability accentuates this analysis.

Our approach uses a model based on MAS

theory to realize wind farm profitability scenarios

based on available budget forecasts and information

on breakdowns that would occur. The main

objective is to evaluate different scenarios and their

profitability providing financial indicators for one or

many failures list to choose the scenario that suits

the operator's requirements.

1.1 The Problem of Maintenance in

Wind Energy Sector

There are several types of maintenance that are used

in wind energy sector:

Preventive maintenance: it aims to reduce the

breakdowns by anticipating them. The interventions

are carried out after a well-defined duration (annual,

semi-annual etc…) or after a signal appearance

following the failure or the going beyond a

threshold. This type of maintenance aims to reduce

the possible risk of breakdown. It corresponds to a

logic of the breakdowns prevention and

maximization of the availability. Ideally for a wind

farm, this type of maintenance is carried out during

the periods of low wind to ensure availability during

the periods of strong winds.

Curative maintenance: used in a single way,

curative maintenance certainly reduced well the

maintenance costs, but it can quickly exceed the

forecasts and causes important disadvantages related

to the production. As the wind farm ages, the

number of corrective increases and generates

indirect costs which it is difficult to estimate before

the breakdowns.

Corrective maintenance: it’s a type of

maintenance made after a diagnosis of breakdown.

Its goal is to set back an element in operating

condition (Hajej and Rezg, 2012). It’s a strategy

which results in an unquestionable advantage

relating to the maximum use of the wind turbine’s

components; in fact, the equipment is replaced or

repaired only in the event of breakdown. It’s also

called the “breakdown” strategy. In the case of a

wind turbine, the failures often occur during period

of strong wind. However, it is in this period that the

wind turbine must be available to the production.

The wind turbine’s stop throughout corrective

maintenance thus involves a consequent production

loss. The single advantage of a corrective

maintenance is that it makes it possible to use the

equipment until exhaustion.

Hybrid maintenance: it is the most current type

of maintenance. It combines the two types of

maintenance: preventive and corrective. It consists

in anticipating some breakdowns by the means of

preventive interventions and being reactive for the

corrective O&M operations when the breakdowns

occur.

Several maintenance tools were developed by

research laboratories and companies. Each one of

these tools adopts an angle of analysis of

maintenance. It can be oriented to some maintenance

fields like spares management or to the whole O&M

field including: spares management, human

resources, installation etc…). For example:

1. SINBAD (Guillon, 2015): is a tool which main

objective is to predict the behaviour of a wind

turbine at any moment. This project was born

from a recommendation of a Franco-British

partnership dedicated to the offshore oil rig to

create a digital tool allowing the visualization of

the tree structure of wind turbines offshore oil

rigs.

2. The OMCE (Operation and Maintenance Cost

Estimator) (Rademakers et al., 2009): it is one of

the most complete models of simulation,

marketed since 2004. The project was initiated

by a consortium including Vestas, Shell Wind

Energy, DTU and ECN (Energy Research of the

Netherlands). It combines three strategies of

maintenance: corrective, preventive and

predictive to predict the annual cost of the

maintenance actions of wind farms. (Onshore

and Offshores) (van de Pieterman et al., 2011).

As inputs, the tool records the components

reliabilities, maintainer information and the

operation to provide maintenance costs.

From the maintenance operator’s point of view, the

problems consist in finding the “optimal” cost of

maintenance that represents balance between an

expected production of the wind farm and a budget

associated with a series of breakdowns planned

during the period. To optimize maintenance, we thus

must optimize the budget of maintenance

(subcontracts and spares) on the wind farms because

it represents the most important owner’s growth

drivers.

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

160

1.2 Strategy of Maintenance over

One-Year Duration and Financial

Indicators

An efficient maintenance strategy is measured by the

reactivity of the team of maintenance, the capacity to

control the costs of parts and the additional costs and

profitability of the wind farm at the end of a period.

In our approach, the final profitability of a wind

farm, over a consequent period of operation, is

expressed by a customized EBITDA (Earnings

Before Interest, Taxes, Depreciation, and

Amortization) indicator. This indicator is called

“Function Cost”: FC (2)

FC= Theoretical turnover - Production

losses -O&M Costs

(2)

FC=ThT - PL -O&M Costs

The theoretical production (3) of a wind turbine is

equivalent to its production with an availability to

100% i.e. no downtime ago over the period. Over a

chosen period, we can obtain a theoretical

production of the wind turbine starting from the

variables of entry which are the data of wind

measured on the wind farm and the curve of real

power.

Data of wind: they represent the speeds of wind

measured by the anemometer-nacelle of the wind

turbine. In the event of unavailability, they are

recovered on the anemometer of the nearest wind

turbine. If no data is provided on the wind turbines,

it will take the data of the mast of measurement

which is located near to the windfarm.

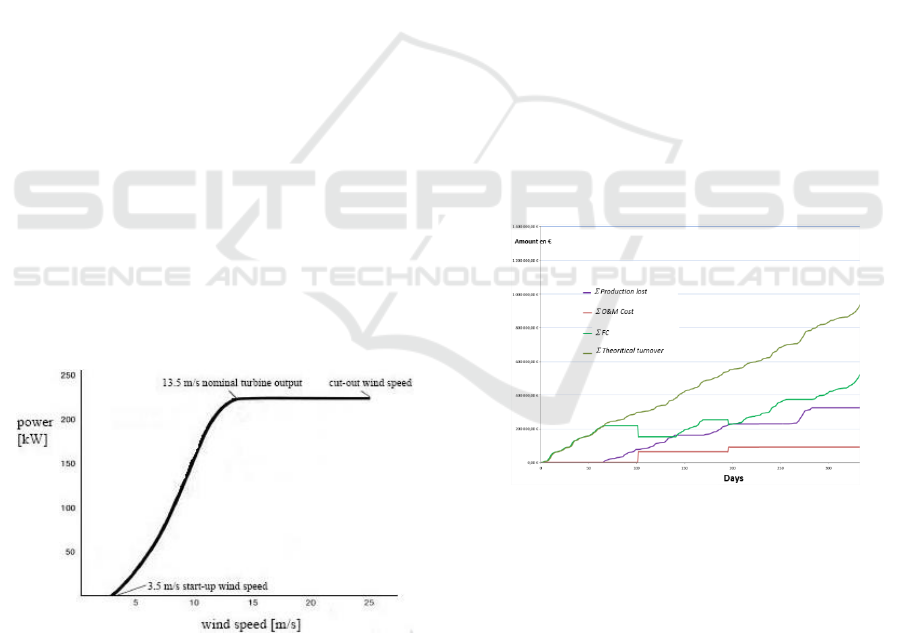

Figure 1: A power curve diagram.

ThT = [

(

Vd

)

∗ Pd(PC)]

∗ kWhPrice(€)

(3)

Where:

▪ ThT: theoretical turnover

▪ Vd: Wind measurement with the period in m/s

▪ Pd: power curve measure

▪ PC: power curve measures kWh

The production loss is defined as a production which

should have been realized for the period when the

wind turbine was stopped; it’s deduced in a

theoretical way. The production loss represents a

shortfall which is calculated by the same formula as

the theoretical turnover but over the duration of

production loss (PL). In this case, we use the same

formula as in (3).

The O&M Cost is related to all maintenance

cost. (4). It can be divided in two parts: spares et

subcontract costs.

O&M Cost (€) = ∑ Spares Costs (€)

+Subcontract cost (€)

(4)

Subcontract cost (€): this cost is related to the

company receiving benefits and which is responsible

for the wind farm maintenance. This company has

an availability rate to reach fixed by contract. In the

facts, the company in charge of maintenance

subcontract is a dissociated company of the farm

owner. The later delegates all the ordinary

maintenance actions.

Spares cost (€): this is the cost of all the parts

used during maintenance operations. This cost is

valued at the end of the stock.

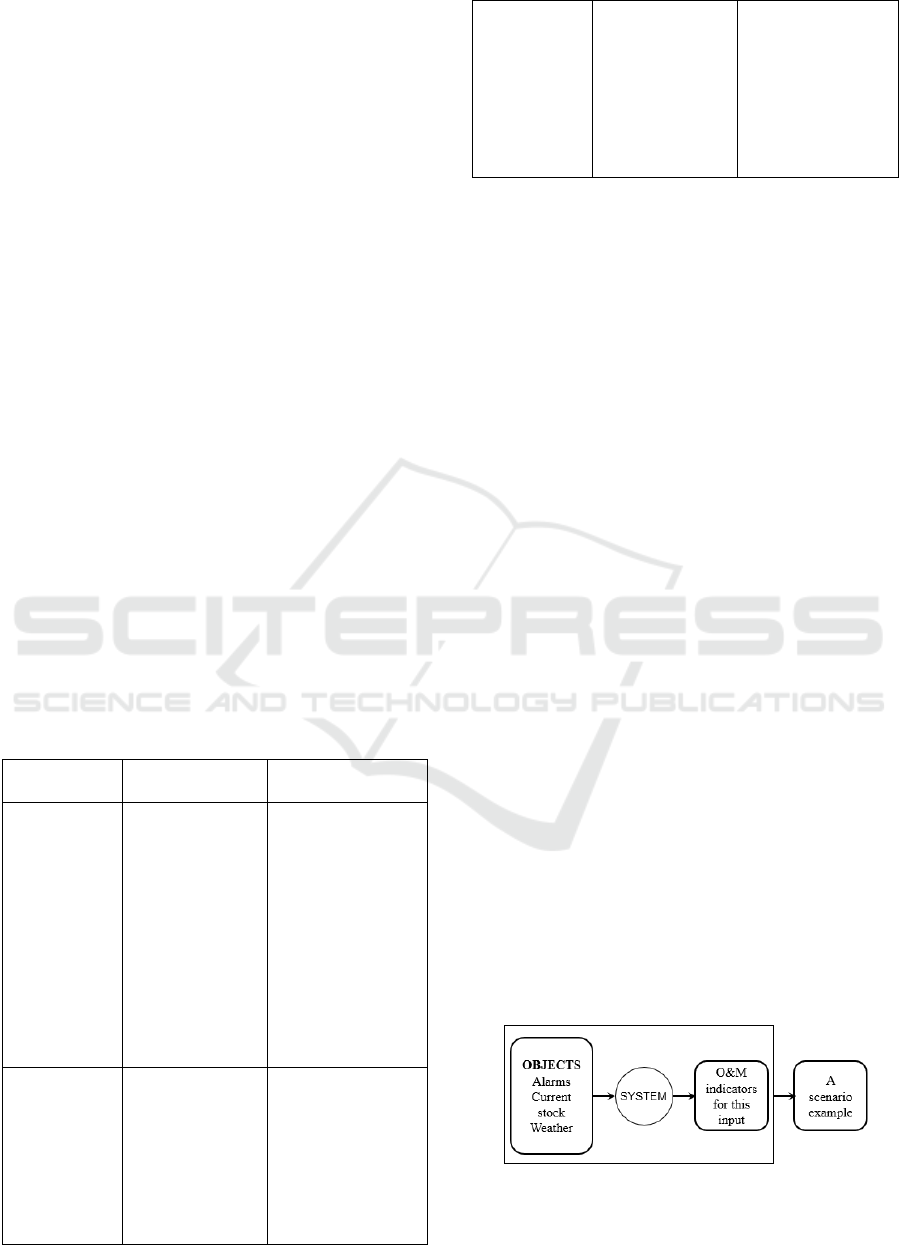

Figure 2: A scenario of the evolution of the indicators in

relation to a series of breakdowns and O&M costs.

Operator estimates maintenance budget at the

beginning period: O&M Cost

estimated

of period; it

may be different at the end of the period O&M Cost

real

. In the present case, three situations may arise at

the end of the period:

1. The forecast of cost is higher than the real

maintenance costs; then maintenance is overpaid

compared to the work completed on the stops:

O&M Cost

estimated

> O&M Cost

real.

2. The expected O&M cost is lower than the final

real cost of maintenance. We suppose then, all

A MAS Model Approach to a Wind Farm Maintenance Strategy

161

other things being equal, that O&M Cost

estimated

<

O&M Cost

real.

3. The ideal situation where the operator has

properly estimated its O & M budget in relation

to the operation of the farm: O&M Cost

estimated

=

O&M Cost

real.

The evaluation consists of analysing the activity of

the wind farm during the period of operation through

the evolution of the O&M indicators over time

(Figure 2).

We will construct this evaluation thanks to

several scenarios that will help the operator in the

choice of his strategy.

1.3 State of Art Discussion and

Problem Definition

The tools for current maintenance are focused on the

wind turbine or the windfarm. These tools can

predict equipment failure that does not allow to

project on the income that can be derived from the

equipment itself.

In our case, at the “Compagnie du Vent”, a

company that manages several wind farms, there

exist a tool named PROMEEO (Platform of

Rationalization and optimization of the maintenance

of the Onshore wind farms). We’ve made a

comparison between the state of art’s tools and

PROMEEO.

Table 1: Comparison of state of art's tools and our tool

PROMEEO.

Tools

State of art’s tools

PROMEEO

Strengths

Tools focused on

turbines, their

operation.

Operational vision

for maintenance

Complete

maintenance

indicators on the

probabilities of

failures

occurrences.

Financial

maintenance-focused

tool

Corresponds to a

management vision

of maintenance

Shortcomings

Incompatibility

with the operation

of a wind farm

operator because

of several models

of different

turbines in a

territory.

Management of

simulation input

parameters: O&M

subcontractor’s time

of maintenance

reactivity.

Improvement of the

There is no

modularity to

follow the

business evolution

and the context of

the wind farm

operator.

prevention of failures

from alerts

Prevention of

defaults on large

components by

analysing the alarms

that precede these

defaults.

We set the problem upside down by optimizing

the wind farm production compared to the

maintenance that can be budgeted.

1.4 The System Agentification

With O&M Multiagent system we can evaluate the

indicators of current and future situations of a wind

farm in real-time with the management of the

evolution of knowledge. The system performs the

simulation of the indicators from the validated input

data (failures list and wind measurements over the

year for theoretical production). We proposed a

scenario calculation which is the expression of a

management of failures over a significant period.

Thus, a one-year (for example) scenario using the

history on-line gives the state of the fleet, the actual

cost of providing maintenance and its profitability.

(figure 3). A scenario S for year n is described by:

Sn = List Pn ∧ O&M Cost n ∧ ThT ∧ FP n

Where:

▪ List P

n

: This list of failures is either recovered

from the year n chosen or constructed fictitiously

from the forecasts of stops.

▪ ThT Theoretical Turnover: Theoretical

production forecast during the analysed period.

▪ Subcontract cost: budget for the period for

maintenance providers.

▪ FC: Function cost (windfarm profitability).

▪ FP: «financial performance» ratio of

performance of the costs compared to the

theoretical turnover (5).

FP(n)=FC(n)/ThT(PC,n)

(5)

Figure 3: A scenario in PROMEEO.

We compare the various indicators of

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

162

profitability according to the various proposals of

maintenance contract anything being equal. Several

scenarios can be provided for the same list of

breakdowns and different subcontract cost. Each

scenario is composed by a series of breakdowns. A

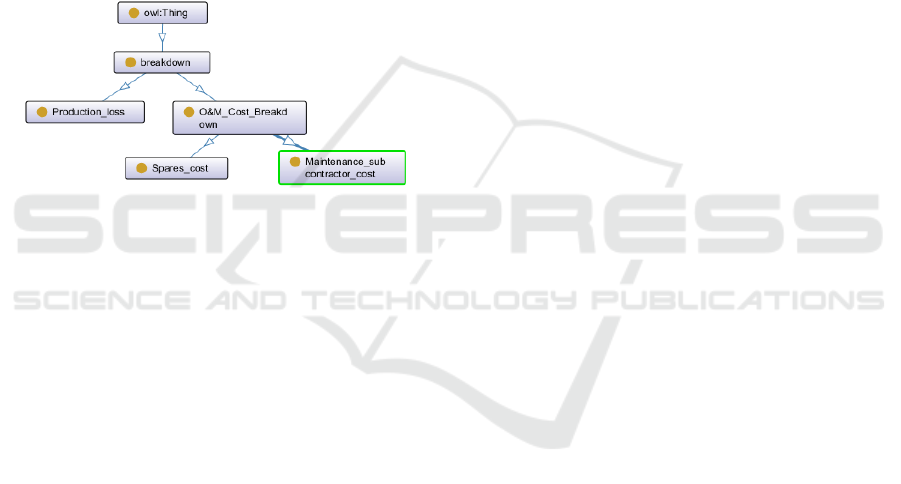

breakdown (Figure 4) involves a production loss and

costs specific to this breakdowns or failures. For

each breakdown, the system calculates the real cost

of maintenance.

O&M Cost

breakdown

= Subcontractor Cost

breakdown

+ Spares

Cost

breakdown

The set of O&M costs is the sum of the breakdown

costs (Σ Ct O&M Cost). Each scenario expresses a

strategy of maintenance of the breakdowns and the

results of the wind farm in terms of performance and

profitability.

Figure 4: From descriptive ontology extract of a

breakdown.

1.5 The Multiagent Model Used to

Develop the Different Scenarios

The multiagent approach is an alternative to more

conventional approaches to cooperation and problem

solving. In general, it can deal with a problem by

decomposing it into simpler sub problems, so that

agents must focus on only one subtask at a time. In

(Ferber and Simonin, 2003), an agent is defined as

an entity driven by a set of trends (satisfaction’s

function to optimize or goals to reach) which has its

own resources and has only a partial representation

of the environment. Its goal is to meet its objectives

while considering its skills, its resources, its

perception of its environment.

An agent is aware of its decision’s capacities and

seeks to achieve a precise goal. Another agent’s

characteristic is its capacity to cooperate with other

environment’s entities. While conforming to its level

of rationality, it can choose to interact, cooperate,

negotiate or limit its interaction with the

environment. An agent, like an object, encapsulates

a state and behaviour but the agent encapsulates its

control on its behaviour; an object has control only

on its state.

In a system with many agents, the goals to reach

can be complementary or contradictory. The agents

can be separated according to the type of relation in

two categories: the competitive agents and the

collaborative agents. A collaborative agent makes

decisions and carries out actions in agreement with

other agents to achieve their respective goals. This

effect of group enables them, consequently, to pool

knowledge and to bind their goals. The environment

of maintenance is composed of agents as well as

objects in the system. The agents present in the

environment are in interaction with objects and other

agents. Whether they are physical or abstract, they

carry out actions to conform to the objectives which

are predefined; the objects can interact with

databases and provide answers at the requests of

other agents.

In our work, an agent has a goal which consists

in modifying the object “Breakdown”, to modify its

state then to share its information with its dealings.

The concepts identified in the descriptive ontology

give us the objects which compose the field of the

O&M. The concepts in the ontology can be at the

same time physical or abstracted elements. The

concept, when it is a physical entity can be

translated in agent if it expresses behaviours, goals.

Each agent must be able to express at least one

objective to reach. Example: the wind turbine (the

equipment) expresses an objective to run with an

availability of 100%. Even if it has an objective of

operation (Availability ratio =100%), its behaviours

are oriented by the O&M indicators values. The

wind turbine cannot be proactive on its environment;

it expresses a set of states which will be evaluated

by indicators. When the concept is a physical entity,

it must be able to express at the same time objectives

and autonomous behaviours to be declined as an

agent.

For example, the indicators are abstract concepts;

the indicator “Cost O&M” (the total cost of

maintenance), has an objective that is to stay low.

The behaviours that it will express will have

consequences on the environment composed by

failures objects and the other agents.

1.6 The Organization of the MAS

According to Environment

Each object “failure” sent in the environment is

described by the following attributes expressing

knowledge:

▪ Failure Id

▪ Turbine Id

▪ A failure description

A MAS Model Approach to a Wind Farm Maintenance Strategy

163

▪ Start and ending date

▪ O&M failure Cost

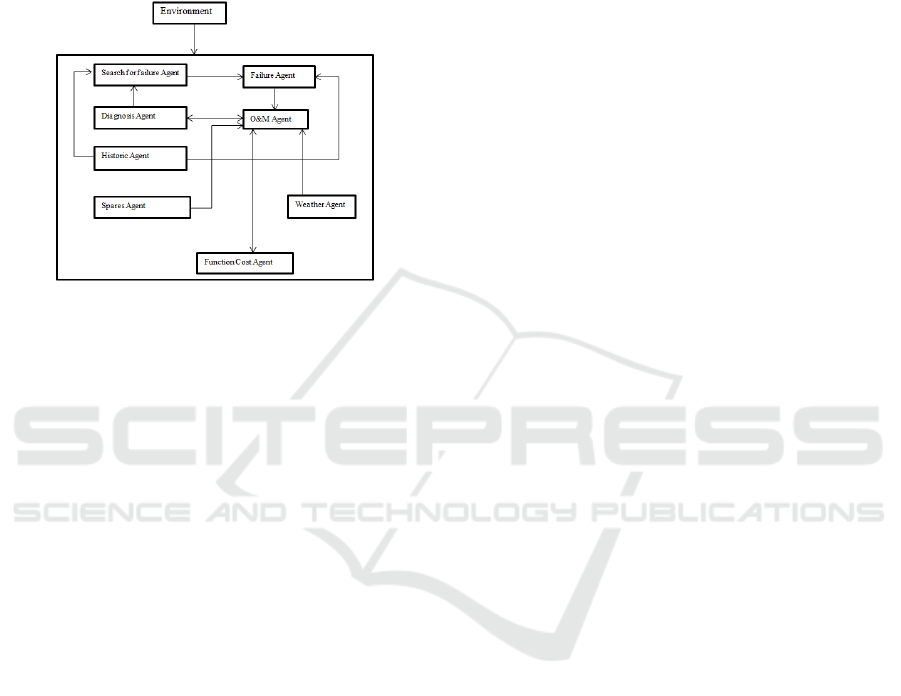

The scenarios are built with PROMEEO. The tool is

based on eight kinds of agents. For a list of failures

given as inputs of the system, the direction of

knowledge communication using agents is shown in

(Figure 5):

Figure 5: MAS model.

For each agent identified in the system, we will

describe its goals and the entities with which it

cooperates.

1.6.1 Search for Failure Agent

▪ Goal: it detects possible failures from alerts and

messages based on the history.

▪ Actions: it sends possible failures as objects to

Failure Agent.

▪ Proactivity: The search for Failure Agent can

be proactive when it detects failure on a wind

turbine. It evaluates, and alerts based on the

probability of occurrence of failures that have

been registered.

▪ Communication: With the SCADA

(Supervisory Control and Data Acquisition).

It retrieves alarms and signals as objects

coming from this entity. It sends to Failure

Agent the list of failures as objects. In

coordination with the Diagnosis Agent, it

recovers the causes of failures that had not

been identified.

1.6.2 Historic Agent

▪ Goal: find former O&M operations for O&M

agent.

▪ Actions: it perceives the failures in progress and

the potential breakdowns and asks for

maintenance operations.

▪ Proactivity: from the details given by O&M

agent, it retrieves the operations that have been

performed for the same failure.

▪ Communication: it provides to the O&M Agent

the breakdowns and asks for the execution of

maintenance actions. With the Search for failure

Agent by receiving information about potential

failures.

1.6.3 Failure Agent

▪ Goal: to close all the breakdowns and to ask for

O&M operations.

▪ Actions: it perceives the breakdowns and failures

in progress and the potential breakdowns and

asks for the maintenance actions.

▪ Proactivity: the agent is proactive in sending the

breakdowns.

▪ Communication: with the SCADA: it recovers

alarms in progress which describe the stopping

of the wind turbine in the event of breakdown. It

provides to the O&M Agent the

breakdowns/failures and asks for the

maintenance actions. It communicates also with

the Search for failure Agent by receiving

information on potential failures.

1.6.4 Diagnosis Agent

Its identifies the breakdowns and their causes. it

perceives the breakdowns, sends the causes and the

list of the parts to be used for the interventions. It

sends to the Search for Failure Agent the causes of

the breakdowns up to that point unknown. It has no

proactivity: no proactivity. Communication: It

provides to O&M Agent the diagnosis Agent.

1.6.5 O&M Agent

It’s equivalent to a maintenance project manager in

the company.

▪ Goal: its main objective is to achieve

maintenance operations ASAP while respecting

the strategy set by the Function Cost Agent. It

provides O&M costs for each failure to the

Function Cost.

▪ Actions: it performs one or more interventions to

resolve received failures. Before each operation,

it sends the total cost to Function Cost Agent.

▪ Proactivity: this agent is responsive during the

failure management.

▪ Communication: its communicates with Failure

Agent by receiving failures as objects; with

Service Provider Agent by receiving their cost

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

164

for the failure management; with Diagnosis

Agent by receiving the spares that will be used

for the operations; with spares Agent: by

receiving available spares for operations; with

provides cost O&M to the Function Cost Agent

that validates the operation.

1.6.6 Service Provider Agent

This agent corresponds to the subcontractor; this

agent oversees the operation execution on the site. In

the system, it sends the Subcontract cost (€).

▪ Goal: it must be able to provide a time of

intervention and the cost of the service.

▪ Actions: for each failure or breakdown, it

provides a person receiving benefits, the cost of

service and the duration of associated

intervention.

▪ Proactivity: it has no proactivity; it only

responses to the requests of the O&M Agent.

▪ Communication: communicate with O&M Agent

by sending the provider cost. (It sends the service

provider chosen and the subcontractor cost).

1.6.7 Weather Agent

It lists the days with favourable weather for

maintenance operations. Proactivity: it responses to

the requests coming from the O&M Agent. The

agent can be proactive when it detects an alteration

(deterioration or improvement) of the weather on the

days it has sent.

1.6.8 Function Cost Agent

This agent validates the execution of the

maintenance action according to profitability.

Within the framework of a calculation, this agent is

responsible for analysing and validates each

operation. We have modelled this agent for

simulations where the system would be constrained

by an objective of profitability. According to the

owner’s strategy based on criteria like the

intervention’s duration or the importance of the

operation’s cost (cost O&M), it validates the

intervention. It is the most important agent in the

system according to the main goal of the system.

▪ Goal: according to the cost of the intervention, it

gives its consent to the execution of the

intervention

▪ Actions: it validates the maintenance operation if

it is consistent with the strategy (internal

argument).

▪ Proactivity: it only responds to requests from the

O&M Agent.

▪ Communication: it communicates with the O&M

Agent to get the “GO” or “NO GO” for the

operation.

1.6.9 Spares Agent

This agent is responsible for spares managements.

Its goal is to answers to spare request for operation

maintenance and send total spares cost (∑Cost

spares

(€)); It communicates with O&M Agent by sending

spares costs and supply delays.

1.7 Running the Agents System

We must implement a lot of agents according to the

categories we have defined. The agents in our

system are not in competition, each one of them

expresses a useful state for its dealings. Considering

the low number of dealings of each agent, the

interaction is direct between the agents. Each agent

is defined by its goal, its rules of behaviour and its

interactions with the other components within the

system. Thus, it has a representation of itself and

environment which surrounds it.

A scenario is the result of the operation of the

wind farm throughout a given period. This operation

considers the possible stops and the estimated

forecasts of wind. Three phases were identified for

the calculation of scenarios:

Firstly, we have “breakdown” event: this

indication gives the state of the wind turbines on the

wind farms. They are the system’s inputs as objects:

ListF (list of failures provided for calculation).

Secondly, the treatment of the breakdowns: at this

step, the failures are studied to know their costs and

effects (lowers availability and production loss) on

the productive apparatus; the system calculates for

each breakdown the cost of maintenance. Thirdly,

the final indicators which give the plan of

maintenance and the cost associated with the

maintenance actions while making it possible to

maximize the profitability of the wind farm

(minimum of loss of availability).

For the user, PROMEEO platform provides a set

of following scenarios with the data input which is

provided. Platform PROMEEO (Platform of

Rationalization and optimization of the maintenance

of the Onshore wind farms) resulting from this

approach is developed for a wind operator (“La

Compagnie du Vent”). The platform establishes the

scenarios with inputs from several data sources

which come from several different applications

A MAS Model Approach to a Wind Farm Maintenance Strategy

165

(figure 6). These applications provide information’s

to PROMEEO database.

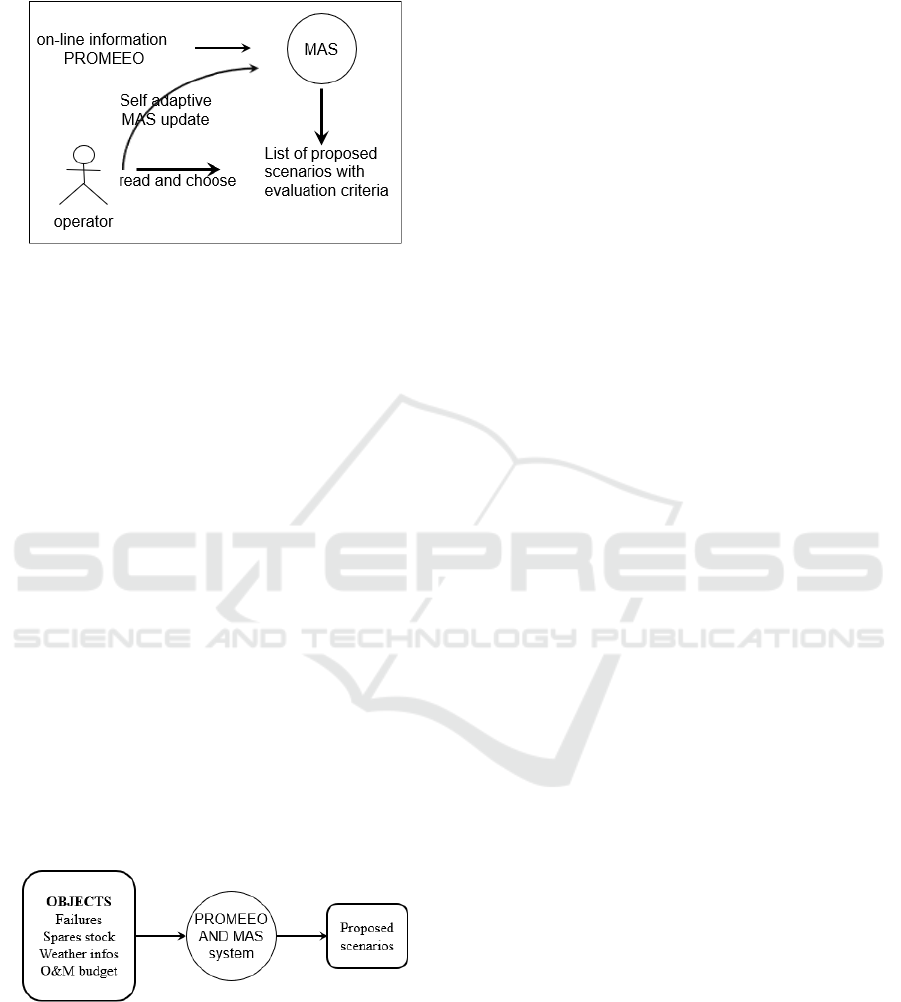

Figure 6: System inputs and outputs.

Presently, we’re developing the agents and the

treatments for the platform. The data inputs were

formatted in a SQL database. The strategies of

maintenance of the wind farms are evaluated

compared to the results of the indicators. The

scenarios depend with time on the relative data to

the breakdowns and the results on indicators

calculated by the platform. The database schema

was designed in UML diagram.

Maintaining industrial equipment doesn’t mean

any more to keep it in a good condition; it means to

achieve goals to maximize the profit which is to get

more than a return on investment. It means also to

preserve the wind turbines for a long time and at

lower costs to amortize the expenses engaged for

construction and the exploitation. O&M Budgets and

subcontracts costs must be regularly revalued to

guarantee efficiency in the wind farms management.

To simulate the real costs of service of a wind farm

means to know the cost of the reactivity of the

maintenance subcontractor. Some questions remain.

For example, wow simulate the maintenance

subcontractor reactivity while varying the

contractual costs within the framework of a forecast?

Figure 7: MAS Operating.

Based on the real-time information produced by

PROMEEO, the MAS evaluates the various

scenarios proposed, improves them, quantifies them

by using its history and the old evaluations available

and proposes them to the operators. According to the

operators' choices, the MAS updates its knowledge

(the criteria of good choice for example) to make

them operational for any other scenario production

action evaluated by the operators (figure 7).

1.8 Conflict Management in the MAS

and Results

The agents in the MAS may face conflicts in the system:

On the failure’s treatment: for each failure, many

indicators are calculated. Their values depend on the

failure’s day start date and an end date. On each

failure, the O&M Agent which validates the failure’s

end date of the maintenance operation by granting to

the “failures object” an end date based on the

information at its disposal. The conflicts that may

arise if we add a couple of constraints for example:

calculate the O&M Cost with a profitability target

(6):

FC= ThT-x-PL

x=ThT-FC-PL

(6)

ThT: the theoretical production cannot be modified;

it represents a fatal data for the operator. The only

optimization action that can be applied is related to

the failures management and consequently

productions loss.

With PL (production loss) which is a function of

maintenance support duration; this duration can be

mechanically reduced but it depends on subjective

criteria such as the responsiveness of the O&M

subcontractor company that we are not able to

quantify.

2 CONCLUSIONS

To be efficient, we have proposed a MAS model for

maintenance that is proactive on the breakdowns,

failures and operations on the windfarm to maximize

profits. The platform is intended to the wind farms

operators. A first prototype is presently under

development towards a professional validation and

that is our first objective. Our final objective is to

produce a MAS system with real-time data and

continuous optimization.

ACKNOWLEDGEMENTS

The work presented in this paper was supported by

the French Foundation of Technological Research

under grant CIFRE N° 2014/0099.

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

166

REFERENCES

Cardon, A. & Mhamed, I., 2012. Systèmes de systèmes.

Autonomy et Proactivity. 9th International

Conference on Modeming, Optimization & Simulation.

Ferber, J. & Simonin, O., 2003. Un modèle multi-agent de

résolution collective de problèmes situés multi-

échelles. JFSMA Déploiement des Systèmes

multiagents, Hammamett (Tunisie) Hermès, pp. pp

317-330.

Guillon, O., 2015. Sinbad, logiciel de prévision de la

maintenance. Production Maintenance, Issue 51.

Mohamed Sahnoun, D. B. A. B., 2014. Modélisation d'un

plan de maintenance baée sur les systèmes multi-

agents pour les éoliennes offshore. Nancy, s.n.

Piana, D., 2016. Resinsight N° 5th Engie Renewable

Seminar.

R.P. van de Pieterman, et al., 2011. Optimisation of

maintenance strategies for offshore wind farms A case

study performed with the OMCE-Calculator. Energy

Research Centre of the Netherlands (ECN).

Amsterdam, s.n.

Rademakers, Braam, H., Obdam, T. & Pieterman, R. v.,

2009. Operation and Maintenance Cost Estimator.

Stockholm, s.n.

Ribrant, J., 2006. Reliability performance and

maintenance - A survey of failures in wind. s.l.:s.n.

Z. Hajej, O. B. N. & Rezg, 2012. Maintenance/Production

plan optimization considering the availability and

degradation of manufacturing system.. Proceedings of

the 14th IFAC Symposium on Information Control

Problems in Manufacturing, pp. 963-967.

Zille, V., 2009. Thesis: Modélisation et évaluation des

stratégies de maintenance complexes sur des systèmes

multi-composants. s.l.:s.n.

A MAS Model Approach to a Wind Farm Maintenance Strategy

167