Internet of Things Applications in Production Systems

A. Boza, B. Cortés, L. Cuenca and F. Alarcón

Research Centre on Production Management and Engineering (CIGIP), Universitat Politècnica de València,

València, Spain

Keywords: Production System, Internet of Things (IoT), RFID, Information Systems.

Abstract: The Internet of Things field has been applied in industries for different purposes. This paper presents a

literature review of Internet of Things applications in the production system. A taxonomy with five

categories has been employed in this review: Sector, Technology, Production Phase, Practical Application

and Benefit. The sectors, technology and production phase where IoT is being introduced practically or

theoretically have been identified, and the benefits of IoT in production systems have been collected and

classified. This research presents the advantages of applying Internet of Things in production systems,

which helps not only production systems managers in practical implementations, but also researchers to

identify research gaps for future research.

1 INTRODUCTION

Although no universal definition exists for Internet

of Things (IoT), the core concept is that everyday

objects can be equipped with identifying, sensing,

networking and processing capabilities, which will

allow them to communicate with one another, and

with other devices and services, over the Internet to

achieve some useful objective (Atzori et al., 2010).

According to Miorandi et al., (2012), the three main

system-level characteristics of IoT are: Anything

communicates, Anything is identified and Anything

interacts.

New technologies are necessary to apply IoT.

Gubbi et al., (2013) identify three more technical

components of IoT: (a) Hardware, made up of

sensors, actuators and embedded communication

hardware; (b) Middleware, in demand storage and

computing tools for data analytics; and (c)

Presentation, novel easy-to-understand visualisation

and interpretation tools which can be widely

accessed on different platforms, and can be designed

for distinct applications.

Based on a review of the literature, Whitmore et

al., (2014) classify IoT applications into the

following domains: smart infrastructure, healthcare,

supply chains/ logistics, and social applications. In

the supply chain/logistics domain, IoT can further

improve efficiency in all the supply chain parts:

production, distribution, transporting, and etc. The

literature includes a few research works about IoT

applied to production. This paper reviews them for

the purpose of acquiring better knowledge about IoT

applied to production, and also about the benefits of

these proposals. We expect to show how the

application of IoT can help managers of the

production system in enterprises. For this review,

Section 2 shows the methodology employed, Section

3 explains the taxonomy used to classify the

different research works, and Section 4 includes the

conclusions drawn from this research.

2 REVIEW METHODOLOGY

The literature on IoT applied to production was

searched in scientific-technical bibliographic

databases Google Academics and Scopus, which

include publishing portals like Elsevier, IEEExplore

or Springer. The literature on IoT applied to

production was searched in scientific-technical

bibliographic databases Google Academics and

Scopus, which include publishing portals like

Elsevier, IEEExplore or Springer.

The search criteria applied were combinations of

“production”, “production system”, “manufacturing”

with “Internet of Things”, ”Internet of

Manufacturing Things” and “IoT” in the titles and

keywords of the papers. In the first search, 31

references were found in the last 4 years (2010-

330

Boza A., Cortés B., Cuenca L. and Alarcón F..

Internet of Things Applications in Production Systems.

DOI: 10.5220/0005378903300337

In Proceedings of the 17th International Conference on Enterprise Information Systems (ICEIS-2015), pages 330-337

ISBN: 978-989-758-096-3

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

2014). These papers were reviewed and 21

references, which actually dealt with the proposal of

this paper, were selected. These references were

obtained from journals (23,81%), book sections

(23,81%) and conferences (52,38%). Table 1 shows

the papers found, the difficulties presented in each

paper and the proposal to solve them with IoT.

3 TAXONOMY

The taxonomy employed in this review considers

five categories. Some of these categories have been

proposed after considering that they have been

helpful in other production and supply chain reviews

like (Mula et al., 2010), (Carnevalli and Miguel,

2008) or (Melo et al., 2009). These categories are:

Sector: this represents the industrial sector where

IoT has been applied; e.g., garments, agriculture, etc.

Each sector has its own production processes.

Technology: this presents the technologies that have

been used to apply IoT.

Production Phase: all the selected references focus

on one part of the production system given the

complexity of this system. This category indicates

the production system phase that the papers have

addressed.

Table 1: Literature reviewed.

Author Problem

Cao et al., (2011) A new architecture of the toy production material tracking system based on key technologies of IoT

Castro et al., (2011)

A management application architecture based on IoT for the identification and classification of

automatic oxygen cylinders to make all the information available during the production process

Cuiyun and Yuanhang (2010) A study of the influence of an IoT application on production and logistics in an enterprise

Houyou et al., (2012)

Automation systems in manufacturing supported by IoT to support flexibility and agility in

manufacturing

Hu et al., (2011)

An IoT monitoring platform to monitor all the critical control points (CCPs) to ensure food safety

during a sausage production process

Isenberg et al., (2011)

Research about suitability and cooperation in collaborative production environments for autonomic and

agile processes based on IoT and autonomous objects

Lee et al., (2012)

The use of radio frequency identification (RFID) technology to capture real-time data, which is helpful

in monitoring resources utilisation during production.

Liu and Xu (2013) An integrated management framework of a satellite product manufacturing workshop based on IoT

Lvqing (2011)

A mechanical production monitoring system based on IoT technology to replace traditional manual

entry method

Meyer et al., (2011)

An approach for a monitoring and control system to enable new ways in which disturbances can be dealt

with in order to increase the robustness of overall plan execution

Qu et al., (2012) A traceability system based on IoT to address the food safety problems of cucumbers

Stephan et al., (2010)

Using Digital Object Memories throughout a product’s life cycle by focusing on the production part of

the value chain

Vossiek et al., (2010)

Skilful combination of different Auto-ID technologies and the incorporation of sensor data provided by

production machinery and control systems

Wang and Chen (2013) A new manufacturing inventory management model based on IoT technology

Wang and Liu (2014)

Applications of IoT technology to the agricultural products supply chain to improve the operation

efficiency of a supply chain of agricultural products

Wuest et al., (2012)

A Product Avatar representation of product lifecycle information of an Intelligent Product on the social

network Facebook

Yuan et al., (2013)

Development of a system based on IoT technology to verify that IoT promotes workshop process

visualisation developments

Zhang et al., (2014)

The proposed IoMT aims to design an easy-to-deployment infrastructure to form an active sensing

manufacturing environment and to timely monitor, control and optimise the production process.

Zhiliang et al., (2013)

A new project that merges Personal Digital Assistant (PDA) in manufacturing shop with Workshop

Internet of Things (WIoT).

Zuehlke (2010)

Smart Factory KL, a multi-vendor research and demonstrator facility for smart production technologies

based on IoT

InternetofThingsApplicationsinProductionSystems

331

Table 2: IoT in production systems: Industrial Sectors.

Sector Author

General

Cuiyun and Yuanhang (2010), Isenberg et al.,

(2011), Houyou et al., (2012), Lvqing (2011),

Meyer et al., (2011), Wang and Chen (2013),

Stephan et al., (2010), Wuest et al., (2012),

Yuan et al., (2013), Zhang et al., (2014),

Zhiliang et al., (2013), Zuehlke (2010)

Agriculture

Qu et al., (2012), Shengduo and Jian (2012),

Wang and Liu, (2014)

Food Hu et al., (2011)

Toys Cao et al., (2011)

Garment Lee et al., (2012)

Metal Vossiek et al., (2010)

Aerospace Liu and Xu (2013)

Chemical Castro et al., (2011)

Practical Application: many research works provide

a proposal as to how to apply IoT in production, but

they do not apply the proposal to a real company. So

this approach indicates if the proposal has been

validated in a real situation or not.

Benefit: this category includes the benefits from

applying IoT in the production system in accordance

with the reviewed literature.

3.1 Sector

Basing on the industrial sector, papers can be

classified into a) a general sector (if the paper

presents an application in production, but does not

specify a sector); or b) a specific sector, where seven

industrial sectors were identified: Food, Toys,

Garments, Agriculture, Metal, Aerospace and

Chemical. Table 2 shows the sectors found and the

authors who applied his approach in each sector.

3.2 Technology

According to (Tan and Koo, 2014), there are three

kinds of technologies in IoT for data acquisition:

two-dimensional code, RFID and sensors. Two-

dimensional (2D) codes use black and white pixels

laid out on a plane to store information. RFID is a

wireless automatic identification technique that uses

radio frequency signals to identify a target and to

obtain messages. Sensors are objects that can

acquire data. This classification has been used as a

basis to review the technologies included in the

reviewed literature. Table 3 provides the data

acquisition technologies to implement IoT.

3.3 Production Phase

According to (Cuatrecasas, 1994), the production

Table 3: IoT in the production system: Technology.

Author 2D codes RFID Sensors Others

Cao et al., (2011) X X X Servers

Castro et al., (2011) X X 6LoWPAN

Cuiyun and Yuanhang

(2010)

X

Server

Houyou et al., (2012) X Wireless network

Hu et al., (2011) X X Wireless network

Isenberg et al., (2011) X X

Lee et al., (2012) X X X Mobile Communication Network, Cameras

Liu and Xu (2013) X X Server, Wireless Network, GPRS

Lvqing (2011) X X X

Meyer et al., (2011) X X X Three dimensional code, GPS, Wireless network, Server

Qu et al., (2012) X 3G

Shengduo and Jian (2012) X X X Video Surveillance Technology, GPS

Stephan et al., (2010) X X Object Memory Server

Vossiek et al., (2010) X X

Wang and Chen (2013) X X

Wang and Liu (2014) X X Wireless and wired network, Server

Wuest et al., (2012) Social Network

Yuan et al., (2013) X X Wireless Network

Zhang et al., (2014) X X Zigbee

Zhiliang et al., (2013) X X Wireless network, LAN, Server

Zuehlke (2010) X X Bluetooth, Zigbee, Wireless Network

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

332

system is composed of three phases: Planning

Operation and Control. Planning is composed of

Sales Forecasting, Capacity Planning, Production

Planning and Production Order and Programming.

The Operation phase includes Replenishment and

Material and Resources Management, Productive

Process and Client Supply. In the control phase, the

company must be sure that product requirements

have been achieved, which represent Production,

Quality and Stock Control.

Table 4: Subphase codes.

Phase Subphase Code

Planning

Sales Forecasting SF

Capacity Planning CP

Production Planning PP

Production Order and

Programming

PO&P

Operations

Replenishment and Material

and Resources Management

R&MRM

Productive Process PPS

Client Supply CS

Control

Production PC

Quality QC

Stock SC

These phases have been used to classify the

reviewed based on the production phase that the

literature authors have dealt with. Table 4 provides

the code of these phases and Table 5 classifies each

paper according to the production phase (or phases)

where IoT has been applied.

3.4 Practical Application

Five references include real IoT applications for the

production area. Lee et al., (2012) apply their

proposal in THC, a Hong Kong-based garment

manufacturing company. Zhang et al., (2014)

presents an industrial case study by applying their

proposed event model to a shop floor to analyse its

key production performance. Isenberg et al., (2011)

design a scenario that illustrates an autonomous

assembly system for an automotive tail-light by

working with IoT. (Vossiek et al., 2010) do not

apply their proposal in any company, but their

research is based on real company information.

Finally, (Castro et al., 2011) carry out a proposal

with collaboration from the operators and/or staff

responsible for managing oxygen cylinders.

The benefits of these real applications have been

included in the following point.

Table 5: Production phases of the reviewed works.

Author

Planning Operations Control

SF CP PP PO&P R&MRM PPS CS PC QC SC

Cao et al., (2011) O O

Castro et al., (2011) O O O

Cuiyun and Yuanhang (2010) X X X

Houyou et al., (2012) X X

Hu et al., (2011) O O

Isenberg et al., (2011) X X

Lee et al. (2012) O X X

Liu and Xu (2013) X

Lvqing (2011) X

Meyer et al., (2011) X X O

Qu et al., (2012) O O

Shengduo and Jian (2012) O O

Stephan et al., (2010) O O

Vossiek et al., (2010) O O

Wang and Chen (2013) X O

Wang and Liu (2014) O

Wuest et al., (2012) O X O O

Yuan et al., (2013) O

Zhang et al., (2014) X X O

Zhiliang et al., (2013) O O

Zuehlke (2010) X X

Total 0 2 1 3 4 9 15 7 3

*X represents the phase of the work indicated by the author.

O represents the phase of the work deduced by the content of the paper.

InternetofThingsApplicationsinProductionSystems

333

3.5 Benefits

Cuiyun and Yuanhang (2010) identify benefits for

the production area into two main groups: 1)

benefits related to information management in

production, 2) Other benefits in production.

According to this identification, all the benefits

found in this review are classified into the following

groups.

In the first group, the benefits found are: unique

identifier, each product has its own identifier in the

production system, without repetition; monitoring

reading information, information is taken

automatically and can be supervised; real-time

information, managers can see all the information on

the real status in production; more accessible

information, managers can take production

information and sharing in the easiest way;

improving information quality, monitoring

information is more accurate and free of errors; and

improving transparency information, it is possible to

obtain further information, which was previously

hidden.

Table 6: Benefits for production systems.

Benefits Acronym

Information

Unique identifier UI

Monitoring reading information MRI

Real-time information RTI

More accessible information MAI

Improving information quality IIQ

Improving transparency of

information

ITI

Other

Reducing production cost RPC

Improving quality production IQP

Improving efficiency IE

Improving service level ISL

Better synchronisation of processes BSP

Reducing overstocking and

understocking

ROU

Monitoring production MP

Better quality product BQP

Other benefits covers reducing production costs,

information is of better quality and the waste

produced by mistakes in production can be avoided;

improving quality production, like detecting real-

time disturbances; improving efficiency, like

reducing energy consumption; improving service

level, with quicker processes and better quality

information; better synchronisation of processes,

due to the real-time information provided; reducing

overstocking and understocking, transparency-

related information avoids possible mistakes in

production and allows better control in production;

monitoring production, due to the intelligence that

IoT provides the system with to better control

production.

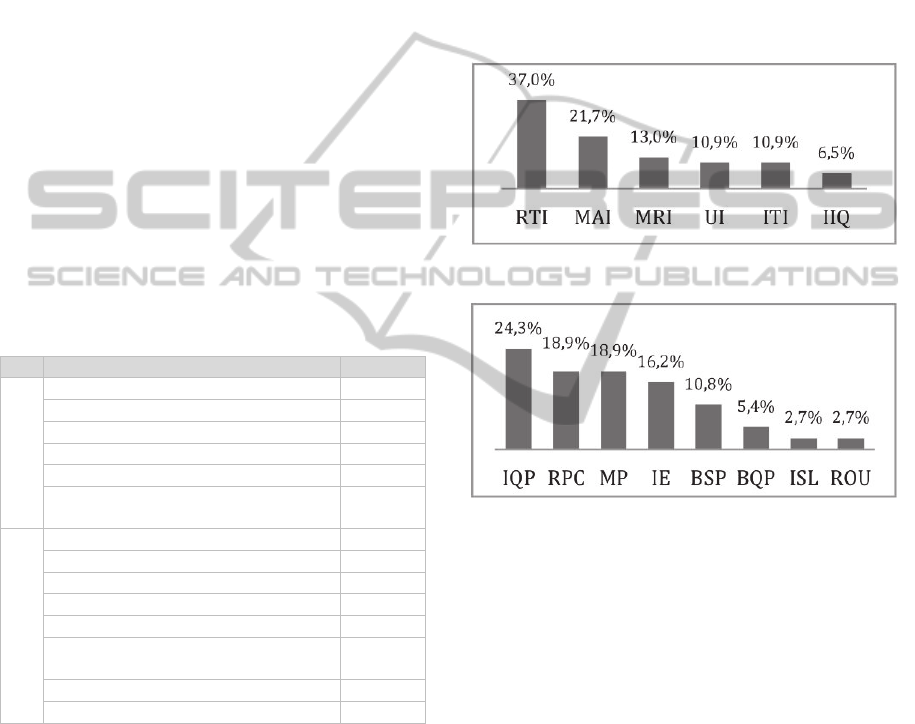

To summarise these benefits, Table 6 provides

acronyms of each benefit. Table 7 identifies the

papers that deal with these benefits and the

percentages of each benefit are represented in the

graphs in Figures 1 and 2. These graphs show that

the most repeated benefit in the first group

(information management) is real-time information

and the most repeated benefit in the second group

(other benefits) is improving quality production.

Figure 1: Percentages of benefits in information.

Figure 2: Percentages of other benefits.

Table 8 identifies the benefits in each production

phase. The cells inside the table show the number of

papers that include the benefit in that phase. The

bottom of the table summarises the number of

benefits cited in that production phase. Very few

papers deal with IoT in the planning and operation

production phase, so reported benefits are limited.

However, it is important to highlight the capacity

planning phase since only two papers deal with this

phase, although ten benefits were identified in these

papers for this phase. The phase with the most

benefits is Client Supply. The benefit that appears

the most is Real-Time Information, which appears in

eight different phases.

4 CONCLUSIONS

This work reviews IoT applications in production

systems. To do this review, a taxonomy based on the

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

334

Table 7: Benefits of the reviewed works.

Authors

Benefits in information Other benefits

UI

MRI

RTI

MAI

IIQ

ITI

RPC

IQP

IE

ISL

BSP

ROU

MP

BQP

Cao et al., (2011) X

Castro et al., (2011) X X X

Cuiyun and Y. (2010) X X X X X X X X X X

Houyou et al., (2012) X X X X

Hu et al., (2011) X X X X X X

Isenberg et al., (2011) X

Lee et al., (2012) X

Liu and Xu (2013) X X X

Lvqing (2011) X

Meyer et al., (2011) X X X X X X X

Qu et al., (2012) X X X

Shengduo and J. (2012) X X X X X

Stephan et al., (2010) X X X X X X X X

Vossiek et al., (2010) X X X X X

Wang and Chen (2013) X X X

Wang and Liu (2014) X X

Wuest et al., (2012) X X

Yuan et al., (2013) X X X X

Zhang et al., (2014) X X

Zhiliang et al., (2013) X X X X X X X

Zuehlke (2010) X X X X X

Total Percentage (%) 11 13 37 22 6 11 19 24 16 3 11 3 19 5

Table 8: Benefits in each production phase of the reviewed works.

SF CP PP PO&P R&MRM PPS CS PC QC SC

UI 0100 0 1252 1

MRI 0 1 0 0 0 1 2 6 2 1

RTI 0 2 1 0 2 3 7 12 5 2

MAI 0 1 0 0 2 1 5 8 3 2

IIQ 0100 0 0222 1

ITI 0 0 0 1 2 0 2 3 3 1

RPC 0 1 0 0 1 3 3 5 2 0

IQP 0 1 0 0 1 2 3 7 4 1

IE 0100 1 1251 0

ISL 0 1 0 0 0 0 1 1 0 0

BSP 0 0 0 0 1 1 1 3 2 1

ROU 0 0 0 0 1 0 1 4 0 0

MP 0001 0 3122 1

BQP 0 1 0 0 0 0 2 2 1 1

Benefits

cited

0 10 1 2 8 9 14 14 12 10

* Cells show the number of papers that include the benefit in that phase

InternetofThingsApplicationsinProductionSystems

335

analysis of five characteristics was used: Sector,

Technology, Practical Application, Production Phase

and Benefit.

By way of conclusion, we can state that IoT is a

new research field in production systems. It is

possible to find general proposals for a wide range

of industrial sectors, but also a specific proposal for

given industrial sectors. However, very few of these

proposals have had a real application in industry.

The predominant technologies in the application

of IoT for production systems are RFID and sensors.

Regarding the planning, operation and control

phases in production systems, the application of IoT

focuses mainly on the control phase.

Most of the found proposals are applications to

production control, followed by quality control and

stock control. All the authors indicate that IoT

applications contribute with benefits in production

systems. These benefits are not only for better

management information in production (e.g., real-

time information or improving information quality),

but also benefits for other aspects of the production

system (e.g., reducing production costs and

improving efficiency).

In this review, some gaps in the literature on IoT

application in production system have been

identified. Based on these gaps and seeing how IoT

applications can help managers of the production

system, some near future lines of research arise: 1)

most proposals are general for the production of any

company, but there are very few applied proposals;

2) the predominant technology used to implement

IoT is RFID. Although it offers many advantages,

IoT with other technologies would be interesting for

it to be applied or combined with it; 3) some

industrial sectors, where experiments with IoT are

being done, have been identified, but new research

works could be conducted in other industrial sectors;

4) IoT Applications in the production area

concentrate mainly on the control phase. Hence

further research should also be conducted in

planning and operation phases and subphases.

ACKNOWLEDGEMENT

This research has been carried out in the framework

of the project PAID-06-21 Universitat Politècnica de

València and GV/2014/010 Generalitat Valenciana

(Emergent Research Groups)

REFERENCES

Atzori, L., Iera, A., & Morabito, G. (2010). The Internet of

Things: A survey. Computer Networks, 54.

Cao, Y. L., Li, W. F., & Song, W. (2011). Research on

Materials Tracking in Toy Production Based on the

Internet of Things. Advanced Materials Research,

314-316.

Carnevalli, J. A., & Miguel, P. C. (2008). Review, analysis

and classification of the literature on QFD—Types of

research, difficulties and benefits. Int. Journal of

Production Economics, 114.

Castro, M., Guillen, A., Fuster, J. L., Jara, A. J., Zamora,

M. A., & Skarmeta, A. F. G. (2011). Oxygen

Cylinders Management Architecture Based on Internet

of Things. In 2011 Int. Conf. on Computational

Science and Its Applications (ICCSA).

Cuatrecasas, L. (1994). Organización y gestión de la

producción en la empresa actual. Barcelona: CPET.

Cuiyun, M., & Yuanhang, H. (2010). Discussion on the

Application of Internet of Things in Logistics

Production Management. In 2010 Int. Conf. on E-

Business and E-Government (ICEE).

Gubbi, J., Buyya, R., Marusic, S., & Palaniswami, M.

(2013). Internet of Things (IoT): A vision,

architectural elements, and future directions. Future

Generation Computer Systems, 29.

Houyou, A. M., Huth, H.-P., Trsek, H., Kloukinas, C., &

Rotondi, D. (2012). Agile manufacturing: General

challenges and an IoT@Work perspective. In 2012

IEEE 17th Conf. on Emerging Technologies Factory

Automation (ETFA).

Hu, T., Zheng, M., & Zhu, L. (2011). Research

Application of the Internet of Things Monitor Platform

in Meat Processing Industry. In J. J. Park, H. Jin, X.

Liao, & R. Zheng (Eds.), Proceedings of the Int. Conf.

on Human-centric Computing 2011 and Embedded

and Multimedia Computing 2011. Springer

Netherlands.

Isenberg, M.-A., Werthmann, D., Morales-Kluge, E., &

Scholz-Reiter, B. (2011). The Role of the Internet of

Things for Increased Autonomy and Agility in

Collaborative Production Environments. In D.

Uckelmann, M. Harrison, & F. Michahelles (Eds.),

Architecting the Internet of Things. Springer Berlin

Heidelberg.

Lee, C. K. H., Choy, K. L., Law, K. M. Y., & Ho, G. T. S.

(2012). An intelligent system for production resources

planning in Hong Kong garment industry. In IEEE Int.

Conf. on Industrial Engineering and Engineering

Management.

Liu, J., & Xu, W. (2013). Technical State Monitoring and

Evaluation of Aerospace Product Manufacturing

Workshop Based on Internet of Things. In Green

Computing and Communications (GreenCom), 2013

IEEE and Internet of Things (iThings/CPSCom), IEEE

Int. Conf. on and IEEE Cyber, Physical and Social

Computing.

Lvqing, Y. (2011). The analysis and design of machinery

production monitoring system based on Internet of

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

336

Things. Presented at the 2011 International

Conference on Electronics, Communications and

Control (ICECC).

Melo, M. T., Nickel, S., & Saldanha-da-Gama, F. (2009).

Facility location and supply chain management – A

review. European Journal of Operational Research,

196.

Meyer, G. G., Hans Wortmann, J. C., & Szirbik, N. B.

(2011). Production monitoring and control with

intelligent products. Int. Journal of Production

Research, 49.

Miorandi, D., Sicari, S., De Pellegrini, F., & Chlamtac, I.

(2012). Internet of things: Vision, applications and

research challenges. Ad Hoc Networks, 10.

Mula, J., Peidro, D., Díaz-Madroñero, M., & Vicens, E.

(2010). Mathematical programming models for supply

chain production and transport planning. European

Journal of Operational Research, 204.

Qu, B., Jing, X., Wang, X., Li, Y., & Liang, Y. (2012).

Design on Cucumber Traceability System Based on

the Internet of Things. In D. Li & Y. Chen (Eds.),

Computer and Computing Technologies in Agriculture

V. Springer Berlin Heidelberg.

Shengduo, L., & Jian, Z. (2012). Research and

Development of Management Platform for Precision

Ecological Agriculture Based on the Internet of

Things. In W. Zhang (Ed.), Software Engineering and

Knowledge Engineering: Theory and Practice.

Springer Berlin Heidelberg.

Stephan, P., Meixner, G., Koessling, H., Floerchinger, F.,

& Ollinger, L. (2010). Product-mediated

communication through digital object memories in

heterogeneous value chains. In 2010 IEEE Int. Conf.

on Pervasive Computing and Communications

(PerCom).

Tan, J., & Koo, S. G. M. (2014). A survey of technologies

in internet of things (Vol. Marina Del Rey, CA).

Presented at the 9th IEEE International Conference on

Distributed Computing in Sensor Systems, DCOSS

2014, IEEE Computer Society.

Vossiek, M., Miesen, R., & Wittwer, J. (2010). RF

identification and localization - recent steps towards

the internet of things in metal production and

processing. Presented at the 2010 18th Int. Conf. on

Microwave Radar and Wireless Communications

(MIKON).

Wang, H., & Chen, X. (2013). Internet of Things

Technology-Based Manufacturing Inventory

Management. In 2013 Int. Workshop on Computer

Science in Sports. Atlantis Press.

Wang, X., & Liu, N. (2014). The application of internet of

things in agricultural means of production supply

chain management. Journal of Chemical and

Pharmaceutical Research, 6.

Whitmore, A., Agarwal, A., & Da Xu, L. (2014). The

Internet of Things-A survey of topics and trends.

Information Systems Frontiers.

Wuest, T., Hribernik, K., & Thoben, K.-D. (2012). Can a

Product Have a Facebook? A New Perspective on

Product Avatars in Product Lifecycle Management. In

L. Rivest, A. Bouras, & B. Louhichi (Eds.), Product

Lifecycle Management. Towards Knowledge-Rich

Enterprises. Springer Berlin Heidelberg.

Yuan, L., Guo, Y., Jiang, J., & Nian, L. (2013). The

Research on Monitoring of Discrete Manufacturing

Process Based on Internet of Things. In Green

Computing and Communications (GreenCom), 2013

IEEE and Internet of Things (iThings/CPSCom), IEEE

Int. Conf. on and IEEE Cyber, Physical and Social

Computing .

Zhang, Y., Wang, W., Liu, S., & Xie, G. (2014). Real-

Time Shop-Floor Production Performance Analysis

Method for the Internet of Manufacturing Things.

Advances in Mechanical Engineering, 2014, e270749.

Zhiliang, F., Xin, W., Guangrong, Y., & Tao, D. (2013).

PDA-Based Application and Research for Workshop

Internet of Things. In Green Computing and

Communications (GreenCom), 2013 IEEE and

Internet of Things (iThings/CPSCom), IEEE Int. Conf.

on and IEEE Cyber, Physical and Social Computing.

Zuehlke, D. (2010). SmartFactory—Towards a factory-of-

things. Annual Reviews in Control, 34.

InternetofThingsApplicationsinProductionSystems

337