An Overview of OR Models for Biomass Supply Chains

Birome Holo Ba, Christian Prins and Caroline Prodhon

ICD-LOSI, Troyes University of Technology, 12 rue Marie Curie, CS 42060, 10004 Troyes, France

Keywords: Biomass Logistics, Supply Chain, Modelling, Simulation, Optimization.

Abstract: The biorefineries of the future will critically depend on efficient supply chains to guarantee continuous

flows of biomass while minimizing logistic costs and environmental impacts. OR techniques can be very

useful to help decision makers to model, evaluate and optimize such complex and large-scale supply chains

at the design stage. This paper provides an overview of the OR models for this recent research domain and

proposes a core-model (mathematical program) for the tactical decision level.

1 INTRODUCTION

The actual biorefineries designed for first-generation

biofuels (like bioethanol from wheat, maize or sugar

cane, or biodiesel from rapeseed or sunflower) raise

criticisms concerning possible pressures on other

crop usages like human food or animal feed

production. This is why the biorefineries of the

future will try to combine various types of biomass,

by valorizing discarded fractions of current crops,

like cotton straw, and using the enormous potential

of plants, like switchgrass and short rotation woods,

to produce non-food crops. Moreover, beyond

biofuels, all these agricultural and forestry resources

will provide renewable raw materials for a broad

range of other products, such as chemicals, fibers,

lubricants, construction materials, etc.

The European Commission has put forward a

proposal for a Directive to achieve by 2020 a 20%

share of renewable energy and a biofuels’ usage

with a target of 10% in transport (European

Commission, 2008).

While research on interesting vegetal species and

biorefinery processes is well developed, the actors

concerned realized only recently that the Achilles'

heel of the planned systems could be the logistic

part. For instance, each type of biomass is produced

during a short period in the year while biorefineries

have a more regular activity. Hence, an efficient

supply chain must be implemented to play the role

of a buffer in between and supply the biorefineries

without shortage. Moreover, as the biomass itself is

relatively cheap, the economic equilibrium of the

whole system critically relies on logistic costs. OR is

an adequate tool to derive quantitative models for

these biomass supply chains, evaluate their

performance and optimize criteria like the total cost

of the chain, the energy consumption and the GHG

(greenhouse gas) emissions.

The goal of this contribution is to depict the OR

models proposed for biomass supply chains, for

readers having a general OR culture but not

specialists in biomass issues. This work is extracted

from a preliminary study conducted by the same

authors in the GENESYS French national project on

the lipids biorefinery of the future. This study has

surveyed more than 150 research articles on biomass

logistics but, due to limited space, only some

representative papers will be cited here, to provide

the interested readers with good entry points. The

papers are selected among recent research papers

considering different decision time frames (i.e.,

strategic, tactical, operational, and integrated) and

proposing some general approaches to model

biomass supply chains.

2 BIOMASS SUPPLY CHAINS

A complete biomass supply chain includes various

activities like cultivation, harvesting, pre-processing

(e.g., drying, baling, granulation), transportation,

handling, storage, conversion processes in the

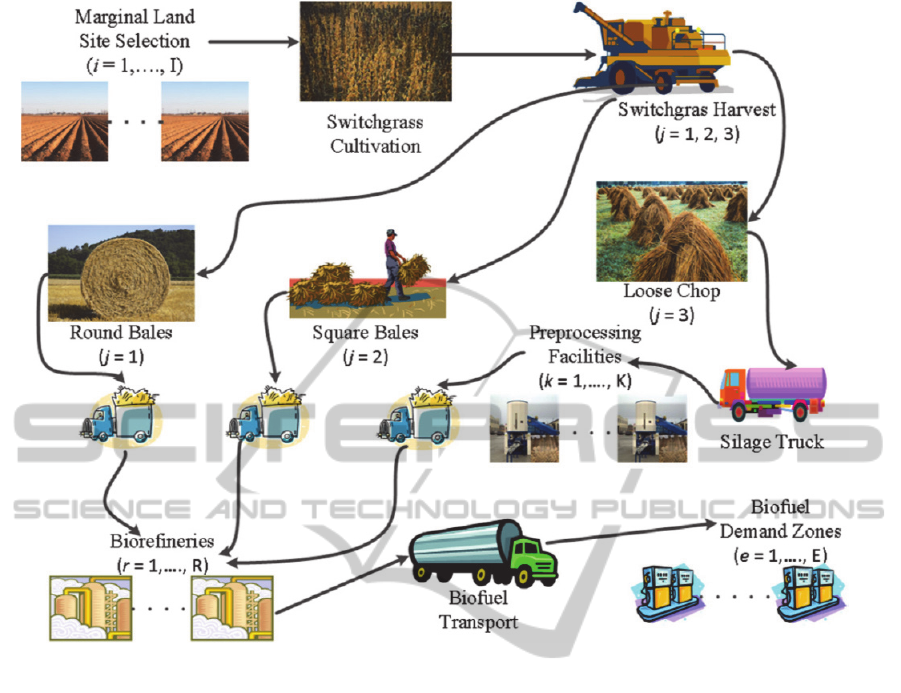

biorefineries, and distribution to end-users. Figure 1

from Zhang et al., (2013) shows a nice example for a

single biorefinery producing ethanol from a plant

called switchgrass. Although a few authors have

tried to model the whole chain (for instance Feng et

174

Ba B., Prins C. and Prodhon C..

An Overview of OR Models for Biomass Supply Chains.

DOI: 10.5220/0004777001740182

In Proceedings of the 3rd International Conference on Operations Research and Enterprise Systems (ICORES-2014), pages 174-182

ISBN: 978-989-758-017-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: Example of supply chain to produce bioethanol from switchgrass (Zhang et al., 2013).

al., (2010) for forest products), a global optimization

is still extremely difficult because very different

actors intervene in the two main parts of the chain,

before and after the biorefineries. Therefore, like in

the vast majority of studies, we consider in the

sequel a supply chain that goes from the fields to the

doors of biorefineries. It is assumed that this chain is

driven by demands issued by refineries for several

types of biomass and that these needs must be

satisfied, if possible.

The structure of the chain in Figure 1 suggests a

network model with the following node types (recall

that from now on we stop at the biorefineries):

Input nodes or production nodes, where biomass

is produced and harvested;

Output nodes or consumption nodes, where

biomass is consumed (biorefineries);

Intermediate nodes, the main ones being storage

sites, pre-processing facilities, transshipment

nodes (railway stations for instance) and simple

transit nodes (villages traversed).

Compared to an industrial supply chain, several

differences must be underlined:

Biomass supply chains cover a vast collection

territory, with many scattered cultivation areas;

Long planning horizons are involved, because

most crops have a one-year cultivation cycle;

Inputs (biomass productions) and outputs

(biorefinery activities) are desynchronized;

Because of degradations, the crops cannot wait

and must be harvested quickly when ready.

Pre-processing activities lead to a longer preser-

vation (dry forms, granulates, pellets) and/or easier

and cheaper transportation (increase in density). For

instance, harvested switchgrass has a density of 60-

80 kg/m

3

, which becomes 140-180 for a bale and

700-800 for granulates (Sokhansanj et al., 2009).

Simple preprocessing like baling is often done

directly on the field by harvesters, like in Figure 1.

Biomass supply chains can also be described in

terms of activities that involve various resources:

Harvesting Activities. They are possible in a

limited period at input nodes, when the crop is

ready, and they compete for a limited fleet of

machines like harvesters or balers. The yield is

not perfect, with a typical 10 to 20% loss.

AnOverviewofORModelsforBiomassSupplyChains

175

Storage. Storage is required in practice to

synchronize the biomass production calendar

with the production planning of the biorefineries.

It can take place in the fields or forests as simple

stacks, in intermediate storage sites or at the

entry of biorefineries.

Pre-processing. Baling is a simple form of pre-

processing, which can be done directly on the

field by a quader-baler. Stronger compressions

and other transformations are possible, but using

heavier equipments and/or dedicated sites.

Transport. Road transport is often preferred, due

to limited accessibility of some production sites

like forests. However, other modes like trains

can be used. In many cases, the fleet of vehicles

is limited and the number of travels per period is

restricted by various constraints like vehicle

range or driving time regulations.

A real biomass supply chain can be much more

complex than the simple example of Figure 1 : other

activities can be distinguished (e.g., material

handling); several types of biomass and a multi-

period horizon can be added; the locations of some

facilities can be left as decision variables, etc.

Hence, biomass supply chain designers need

modeling tools to cope with this complexity. Before

coming to a total cost, they must understand the

dynamics of the chain and fix many variables, like

the amounts harvested (which type of biomass,

where, when, in which amount), the flows in the

network (amounts transported), the advisable stock

levels, the resources consumed (machines, vehicles,

energy, manpower). Subtle tradeoffs must be found:

for instance, deciding either to densify on the field,

using light equipment, or to get a higher density at a

remote dedicated facility, at the expense of an

additional transportation step.

Like in production management and industrial

logistics, the decisions can be classified into three

levels, according to the time horizon concerned:

Strategic decisions include for instance the

selection of accepted biomass types, the location

and size of biorefineries, storage sites and pre-

processing plants, the transportation modes, the

long-term supply contracts. In general, a single-

period horizon of one year or a multi-period

horizon of a few years is considered.

Tactical decisions correspond to production

planning in industry. A multiperiod horizon of a

few months is involved, with a time period

varying from one day to one month. Examples:

amount of each type of biomass harvested in

each period at each production node, vehicle

fleet size, definition of safety stock levels, etc.

Operational decisions correspond to scheduling

in industry. Contrary to the tactical level, the

order and starting times of tasks are specified.

Examples: vehicle routing and scheduling,

detailed harvesting operations, idle times.

Even if some studies address the operational level

(e.g., truck scheduling in Han and Murphy, 2012),

research on biomass supply chains focuses on the

strategic and tactical decision levels. Indeed, the

goal is to provide decision makers with tools to

model a chain before its implementation, and not to

develop software for day-to-day operations.

Anyway, the data for detailed operations are never

known at the design stage.

Three main approaches presented in the sequel

are used to model biomass supply chains: simple

decision support systems, performance evaluation

tools, and optimization techniques.

3 SIMPLE SYSTEMS

The simplest decision support systems rely on

spreadsheets and geographical information systems

(GIS). Their apparent simplicity must not hide the

underlying need for many accurate data, e.g.,

biomass production statistics, cost estimates for all

steps and (for the GIS) geographical maps.

A good example of spreadsheet-based system is

described by Delivand et al., (2011) to assess the

supply of rice straw in Thailand. A detailed cost

analysis of a typical rice straw logistic process for

two baling options (small or large rectangular bales)

in three regions shows that the difference in logistic

costs is finally marginal, due to the higher ownership

and operating costs of the equipment for using large

rectangular bales. However, the fuel consumption is

substantially lower for large bales, which induces a

significant reduction of transport costs.

GIS are more powerful and perform non-trivial

calculations for the user. The centroid of a polygon

describing a cultivation area can be easily computed,

e.g., to estimate the Euclidean distance between this

area and a plant. In case of accessibility problem in a

forest, the GIS can find the closest road.

Brechbill et al., (2011) determine up-to-date

biomass production costs using recent prices for all

important cost components including seed, fertilizer,

herbicide, mowing/shredding, raking, baling,

storage, handling, and transportation, from the fields

to the plant gate. The role of the GIS used (ArcMap)

is to map production and supply data over selected

geographical locations.

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

176

GIS are also used as nice visualization tools on

top of simulation or optimization software. For

instance, Frombo et al., (2009) present a GIS-based

Environmental Decision Support System (EDSS) to

define planning and management strategies for the

optimal logistics for energy production from woody

biomass. The EDSS is organized in three modules

(GIS, data management system, optimization). In

particular, through a GIS-based graphic interface, a

decision maker can visualize the forest parcels of the

territory under concern, select those parcels that can

be used, calculate the distance from each parcel to

the first available road and to the conversion plant

location, and set the parameters related to costs and

technical issues. Then, the optimization module can

be run and the results stored in the database and

displayed on a map.

4 PERFORMANCE VALUATION

The aim of performance evaluation techniques is to

compute performance indicators for real systems

characterized by a complex structure, dynamic

aspects, random variables and/or objective functions

whose each computation is time-consuming (for

instance when these functions have no analytical

formula). The main performance evaluations tools

are simulation methods, stochastic processes like

Markov chains and queuing systems, and Petri nets.

The ones used for biomass logistics are mainly

simulation models. In general, a network-like model

composed of graphical objects (workstations,

queues, random event generators) is defined using

the modelling language of a commercial simulation

software like Arena, then the software simulates in a

few minutes a long period of activity of the real

system.

Sokhansanj et al., (2006) developed a dynamic

Integrated Biomass Supply Analysis and Logistics

model (IBSAL) to simulate the collection, transport

and storage operations and the flow of biomass (corn

stover) from fields to a biorefinery daily throughout

the year. The model includes weather conditions

such as rain and snow which influence the moisture

content and the dry matter loss of biomass through

the supply chain. IBSAL predicts the number and

size of equipment to meet the rate of harvest and

biorefinery demand schedule for feedstock, and also

calculates the costs, energy input and emissions.

IBSAL is very popular as one of the most

sophisticated simulation models, reproducing a

multi-period supply chain with hundreds of

production areas, but with one type of biomass only.

Kumar et al., (2007) applied it to study the logistics

of switchgrass and compare several options for the

collection and transport. IBSAL was also used to

analyze the logistics of different cultures in different

regions (Mani et al., 2006) and (Stephen et al.,

2010). An extended simulation model, called

IBSALMC (IBSAL Multi Crop) was derived from

IBSAL by Ebadian et al., (2011). This model was

developed to evaluate a chain supplying multi-

agricultural raw materials for a proposed cellulosic

ethanol production in Canada.

Ravula et al., (2008) designed a simulation

model to study transport in the logistic network of

cotton, as a possible model for more general biomass

transportation systems. In general, cotton is

collected and compressed into large blocks, known

as modules of cotton transport. Then the cotton

modules built by several farmers are transported to a

gin for processing. Considering a continuous supply

of cotton modules, the originality of this study is to

solve a zero-one knapsack sub-problem which is

solved to optimality to estimate the number of trucks

required in each period. In fact, this work belongs to

the rare publications combining simulation and

optimization.

Zhang et al., (2012) also selected a simulation

approach to take into account the main activities of

the supply chain of biomass, including harvesting,

processing, transportation and storage. Their model

considers the cost of raw materials delivered, energy

consumption and GHG emissions as criteria for

measuring system performance. Compared to the

authors previously cited, this work includes the

distribution sub-network, i.e., beyond the refinery.

Compared to mathematical programming

models, the main advantages of simulation

approaches are the following:

A fine-grain modelling is possible, tackling for

instance resource conflicts, queues of vehicles

waiting for loading in the fields, biomass

production variations or delays due to

unexpected climatic conditions, etc.

System dynamics can be appraised.

Stochastic events are possible.

The operational level can be handled.

Large and complex chains can be modelled.

Practitioners like this kind of models, that they

can easily understand and even modify.

However, simulation models have also some limits:

The running time can be huge for large supply

chains or long time horizons.

No optimization is possible: the user defines the

input parameters and obtains the corresponding

AnOverviewofORModelsforBiomassSupplyChains

177

performance indicators.

In practice, it is possible to evaluate only a few

scenarios to select the best one. For instance, if a

biorefinery is not yet located, a simulation model

can be used to compare a few possible locations,

while ad-hoc variables in a mathematical

program can lead to an optimal location.

5 OPTIMIZATION MODELS

5.1 Principles and Main Works

The formalism used in optimization models is quite

different. The decisions must be described in terms

of variables while the constraints to satisfy are

expressed as equations which link these variables.

Most works consider mixed integer linear programs

(MILP) with a single objective function.

Tembo et al., (2003) are worth citing as one of

the first complete models. They developed a multi-

region, multi-period MILP handling alternative

feedstock, feedstock production, field losses,

harvests, storage, storage losses, transport, bio-

refinery size, and biorefinery location. To take into

account the fluctuations in biomass availability, one-

month time slots are considered. The solution

minimizing logistic costs indicates the best locations

and sizes of warehouses, the storage policies, the

flow of biomass in the logistic network, the planning

of annual crops, the required vehicle fleet, and the

optimal location of the biorefinery.

More recently, Ekşioğlu et al., (2009) proposed

another MILP model that uses agricultural and

woody biomass to produce ethanol. Their multi-

period model prescribes strategic decisions such as

the location, number and size of refineries and

collection sites, and tactical decisions like material

flows. The objective is to minimize over one year a

sum of costs concerning biomass (harvest, storage,

transport, conversion) and the distribution of

ethanol. Ekşioğlu et al., (2010) extended this study

to different modes of transport. The objective was to

identify locations for refineries, transportation

modes to use, transport planning and biofuel

production scheduling to minimize the total cost for

delivering the fuels to end-customers.

Zhu et al., (2011) designed also a MILP for a

single product (switchgrass) supply chain, involving

strategic decisions about the design of the supply

chain and tactical decisions over an annual schedule.

The planning horizon is discretized into one-month

time slots. The MILP takes into account biomass

seasonality, harvesting and transport operations,

energy consumption, and residue handling. The

model determines the best location and capacity for

new warehouses, an effective policy for storage, the

flows of switchgrass transported in the logistic

network, the timing of annual harvest and the best

configuration from a set of candidates bio-refineries.

Zhu and Yao (2011) extended the previous work to a

biorefinery accepting three types of biomass

(switchgrass, corn stover and wheat straw). An

original aspect of their study is that additional

biomass can be purchased from external sources.

The previous papers consider as objective

function a linear combination of various costs,

which is not considered as a true multi-objective

optimization. Multi-objective approaches in Pareto's

sense are all very recent. For instance, Santibañez-

Aguilar et al., (2011) investigated a multi-objective

optimization model for the optimal planning of a

biorefinery, considering various types of production

technologies, raw materials and products. The model

was applied to a case study of a refinery in Mexico.

It simultaneously maximizes the profit and

minimizes the environmental impact.

A few authors have studied non-linear

programming formulations, although they can be

quite hard, computationally speaking. A good

example can be found in Shabani and Sowlati

(2013), who designed a nonlinear mixed integer

program (MINLP) to optimize the supply chain of a

biomass power plant in Canada. Biomass

procurement, storage, energy production and ash

management are considered at the tactical level to

maximize the profit. The model provides estimates

of the amount of biomass to be purchased, stored

and consumed in each month, over a one-year

planning horizon.

The mathematical models solved by commercial

solvers are still limited to small networks in terms of

nodes, contrary to simulation models for instance.

However, still very few authors have proposed

metaheuristics to tackle larger problems. For

instance, Vera et al., (2010) compared a Binary

Particle Swarm Optimization (BPSO) metaheuristic

and a genetic algorithm (GA) to efficiently

determine the optimal location of a biomass power

plant, avoiding a greedy exhaustive search which

would be too time-consuming. The proposed

approach allows to get the location, plant size and

supply area that offer the best profitability from the

investor's perspective.

Optimization models offer the following

advantages compared to simulation:

Optimal decisions can be taken;

Tactical and strategic levels are easily tackled;

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

178

Commercial solvers with a high-level modelling

language are available.

But they have still some drawbacks:

The model is difficult to modify for end-users.

The running time may be excessive when integer

variables or non-linearity are involved.

Commercial solvers fail on large instances and

dedicated algorithms must be designed, e.g.

metaheuristics or decomposition approaches.

Handling stochasticity and multiple objectives is

not obvious, although ad hoc extensions exist.

5.2 A Detailed Example

To fix ideas, we propose a tactical model of biomass

supply chain, inspired by the different models from

the literature but more general and flexible. We

allow both a multi-period planning horizon , a set

of biomass types (e.g., corn straw, switchgrass), a

set of biomass forms or "products" (e.g., straw

bales, straw pellets, switchgrass briquettes), a set of

production zones , a set of storage sites , a set of

transformation (pre-processing) sites and a set of

biorefineries .

The supply chain structure is described by a

digraph with a node-set ∪∪∪ and

an arc-set . models the real road network but

simple transit nodes are removed and each arc ,

stands for a path from node to node in the actual

network, with a length

pre-computed by a

shortest path algorithm. The chain considered covers

a biomass basin corresponding to one French

department, so any implicated arc is traversed in a

single period. It is assumed that each production

node, storage node and preprocessing node is

dedicated to a single product (several products are

easily handled by placing several nodes at the same

location). Our model involves the following data.

For each type of biomass ∈:

set of products for this biomass, e.g.,

bales and pellets from wheat straw.

For each product ∈:

type of biomass of origin, e.g. wheat straw

for straw bales and straw pellets;

density in tons/m

3

;

dry fraction, e.g. 0.8 for 20% humidity.

For each production zone ∈:

delivered product;

harvest window (set of consecutive periods);

amount available in tons;

harvesting capacity in tons/period;

harvesting cost in €/ton.

For each storage site ∈:

stored product;

storage capacity in tons;

storage cost in € per ton and per period.

For each preprocessing site ∈:

input product;

output product (same biomass of origin);

weight conversion factor (e.g., 0.9 if 10

tons on input yield 9 tons on output);

transformation capacity in tons/period;

transformation cost per ton.

For each refinery ∈:

set of accepted biomass types in ;

demand for biomass type in period ,

in dry tons.

For each arc , ∈ :

arc length in km;

transportation cost in € per ton of product .

Variables (amounts in tons)

0,∀∈,∀∈

∶ amount harvested per

zone and period;

0,∀∈,∀∈: stock level for each

storage node and period;

0,∀∈,∀∈: amount of input product

treated for each transformation node and period;

0,∀

,

∈,∀∈,∀∈: flow for

each arc, product and period.

The minimization of the different costs of the chain

can be modeled by the linear program given on next

page, in fact a kind of multi-commodity, minimum

cost flow problem (declarations of variables are not

recalled).

The objective function (1), to be minimized, is

the total cost of operations, composed of four terms:

harvesting costs, storage costs, preprocessing costs

and transportation costs. Constraints (2) to (4)

concern production zones: equations (2) mean that

the sum of product flows leaving the zone is equal to

the amount harvested, equations (3) ensure that this

amount does not exceed harvesting capacity, while

equations (4) state that the total amount harvested

while the crop is ready cannot exceed crop

availability. Constraints (5) guarantee the inventory

balance at each storage site while constraints (6)

prevent storage capacity overflows. Constraints (7)

mean that the amount processed at each

AnOverviewofORModelsforBiomassSupplyChains

179

preprocessing plant corresponds to the sum of

incoming flows. Constraints (8) say that this amount

is equal to the sum of outgoing flows after

preprocessing. The capacity of preprocessing plants

is respected via constraints (9). Finally, biorefineries

are handled by constraints (10), which state that the

demands expressed in dry weight for each accepted

biomass type and each period are satisfied.

This model is very flexible because the user may

interleave freely storage nodes and transformation

nodes between the input layer (production zones)

and the output layer (refineries).

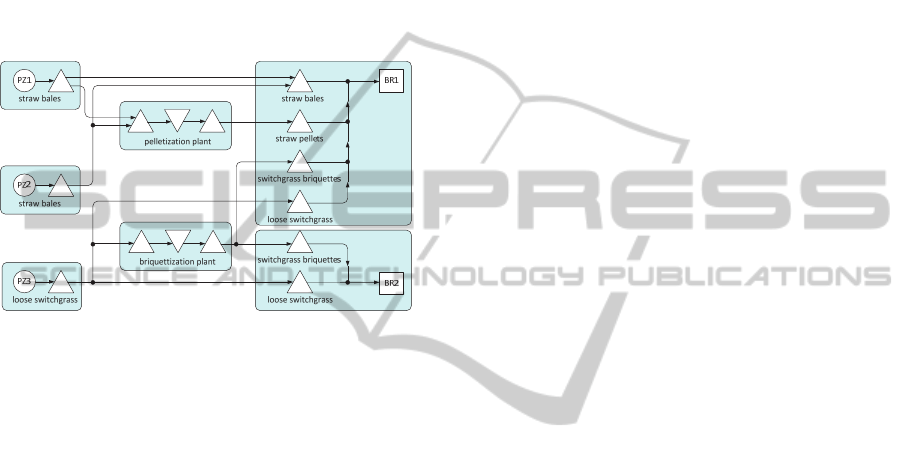

Figure 2: Example of supply chain tackled by our model.

Figure 2 shows an example of possible network

with seven sites: three production zones, two

preprocessing plants and two biorefineries (BR),

respectively symbolized by circles, inverted

triangles and squares. All these sites have local

stocks depicted by triangles.

Production zones PZ1 and PZ2 supply straw

already packed into bales while PZ3 yields loose

switchgrass. Refinery BR1 accepts straw and

switchgrass, but refinery BR2 switchgrass only.

Straw bales can be sent directly to BR1, or to the

first preprocessing plant for pelletization.

Switchgrass can be shipped to BR1 and BR2, or to

the other preprocessing plant to give briquettes. Both

plants have local stocks on input and output.

The core-model has been tested on such

examples, using the OPL-STUDIO modeling

environment from IBM (based on CPLEX) and

providing some preliminary results.

6 CONCLUSIONS

This short review indicates that interesting

optimization problems are raised by the design of

biomass supply chains. Compared to industrial

logistics, many input nodes scattered over vast

territories have to continuously supply output nodes

with biomass produced by slow-growing crops,

which leads to large-scale models.

min

∙

∈

∈

∙

∈∈

∙

∈∈

∙

∙

∈,∈

(1)

∀ ∈ ,∀ ∈

:

,,,

∈

(2)

∀ ∈ ,∀ ∈

:

(3)

∀ ∈ :

∈

(4)

∀ ∈ ,∀ ∈ :

,

,,

,

∈

,,

,

∈

(5)

∀ ∈ ,∀ ∈ :

(6)

∀ ∈ ,∀ ∈ :

,,

,

∈

(7)

∀ ∈ ,∀ ∈ :

∙

,,

,

∈

(8)

∀ ∈ ,∀ ∈ :

(9)

∀ ∈ ,∀ ∈

,∀∈:

∙

∈∈

(10)

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

180

Our analysis of literature has shown that the

genericity of proposed models is still insufficient.

Very few can cope simultaneously with several

types of biomass, a multi-period horizon, strategic

and tactical decisions. We are also surprised by a

majority of articles that neglect storage nodes,

contrary to our model.

Moreover, most authors belong to laboratories of

agriculture, chemistry or energy. Their models are

often solved on small instances, using commercial

software. OR scientists can contribute to the field by

designing dedicated methods based on relaxation or

metaheuristics to solve larger instances in acceptable

running times, and by designing more advanced

models which could incorporate further criteria such

as economic, environmental and social measures,

and further features as uncertainty and sustainability

issues. The next step of our work is to enrich our

model to make it more generic and scalable, and to

study decomposition techniques, relaxation methods,

and a metaheuristic for large problems.

ACKNOWLEDGEMENTS

This work was carried out, in partnership with the

SAS PIVERT, in the frame of the French Institute of

Excellence in the field of Low-Carbon Energies

(IEED) PIVERT (www.institut-pivert.com) selected

as an Investment for the Future ("Investissements

d’Avenir"). This work was supported, as part of the

Investments for the Future, by the French

Government under the reference ANR-001.

REFERENCES

Brechbill, S. C., Wallace, E. T., Klein, E. I., 2011. The

Economics of Biomass Collection and Transportation

and Its Supply to Indiana Cellulosic and Electric

Utility Facilities. BioEnergy Research, 4, 141–152

Delivand, M. K., Barz, M., Gheewala, S. H., 2011.

Logistics cost analysis of rice straw for biomass power

generation in Thailand. Energy, 36(3), pp. 1435–1441.

Ebadian, M., Sowlati, T., Sokhansanj, S., Stumborg, M.,

Townley-Smith, L., 2011. A new simulation model for

multi-agricultural biomass logistics system in

bioenergy production. Biosystems Engineering,

110(3), 280–290.

Ekşioğlu, S., Acharya, A., Leightley, L. E., Arora, S.,

2009. Analyzing the design and management of

biomass-to-biorefinery supply chain. Computers &

Industrial Engineering, 57(4), 1342–52.

Ekşioğlu, S., Li, S., Zhang, S., Sokhansanj, S., Petrolia,

D., 2010. Analyzing the Impact of Intermodal

Facilities to the Design and Management of Biofuels

Supply Chain. Transportation Research Record, 2191,

144-151.

European Commission. Proposal for a Directive of the

european parliament and of the council on the

promotion of the use of energy from renewable

sources. COM(2008) 19 final. Brussels.

Feng, Y., D’Amours, S., Lebel, L., Nourelfath, M., 2010.

Integrated bio-refinery and forest products supply

chain network design using mathematical program-

ming approach. Report 2010-50, CIRRELT, Montréal.

Frombo, F., Minciardi, R., Robba, M., Rosso, F., Sacile,

R.., 2009. Planning woody biomass logistics for

energy production: A strategic decision model.

Biomass and Bioenergy, 33(3), 372–383.

Han, S. K., Murphy, G. E., 2012. Solving a woody

biomass truck scheduling problem for a transport

company in Western Oregon, USA. Biomass and

Bioenergy, 44, 47–55.

Mani, S., Tabil, L. G., Sokhansanj, S., 2006. Effects of

compressive force, particle size and moisture content

on mechanical properties of biomass pellets from

grasses. Biomass and Bioenergy, 30(7), 648–654.

Ravula, P., Grisso, R., Cundiff, J., 2008. Cotton logistics

as a model for a biomass transportation system.

Biomass and Bioenergy, 32(4), 314–32.

Santibañez-Aguilar, J. E., González-Campos, J. B, Ponce-

Ortega, J. M., Serna-González, M., El-Halwagi, M.

M., 2011. Optimal planning of a biomass conversion

system considering economic and environmental

aspects. Industrial & Engineering Chemistry

Research, 50(14), 8558–8570.

Shabani, N., Sowlati, T., 2013. A mixed integer non-linear

programming model for tactical value chain

optimization of a wood biomass power plant. Applied

Energy, 104, 353–361.

Sokhansanj, S., Kumar, A., Turhollow, A., 2006.

Development and implementation of integrated

biomass supply analysis and logistics model (IBSAL).

Biomass and Bioenergy, 30(10), 838–847.

Sokhansanj, S., Mani, S., Turhollow, A., Kumar, A.,

Bransby, B., Lynd, L., Laser, M., 2009. Large scale

production, harvest and logistics of switchgrass

(Panicum vigatum L.) – current technology and

envisioning a mature technology. Biofuel, Bioproduct,

Biorefinery, 3, 124-141.

Stephen, J. D., Sokhansanj, S., Bi, X., Sowlati, S., Kloeck,

T., Townley-Smith, L., Stumborg, M. A., 2010. The

impact of agricultural residue yield range on the

delivered cost to a biorefinery in the Peace River

region of Alberta, Canada. Biosystems Engineering,

105(3), 298-305.

Tembo, G., Epplin, F. M., Huhnke, R. L., 2003.

Integrative investment appraisal of a lignocellulosic

biomass-to-ethanol industry. Journal of Agricultural

and Resource Economics, 28(3), 611-633

Vera, D., Carabias, J., Jurado, F., Nicolás, R., 2010. A

honey bee foraging approach for optimal location of a

biomass power plant. Applied Energy, 87(7), 2119–27.

Zhang, J., Osmani, A., Awudu, I., Gonela, V., 2013. An

AnOverviewofORModelsforBiomassSupplyChains

181

integrated optimization model for switchgrass-based

bioethanol supply chain. Applied Energy, 102, 1205–

17.

Zhang, F., Johnson, D. M., Johnson, M. A., 2012.

Development of a simulation model of biomass supply

chain for biofuel production. Renewable Energy, 44,

380–391.

Zhu, X., Li, X., Yao, Q., Chen, Y., 2011. Challenges and

models in supporting logistics system design for

dedicated-biomass-based bioenergy industry.

Bioresource Technology, 102(2), 1344–51.

Zhu, X., Yao, Q., 2011. Logistics system design for

biomass-to-bioenergy industry with multiple types of

feedstocks. Bioresource Technology, 102(23), 10936–

10945.

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

182