Plant Level Framework for Material Flow in a Nuclear Reprocessing

Facility

Hyo Jik Lee, Won Il Ko and Han Soo Lee

Korea Atomic Energy Research Institute, Daedeok-daero 989-111, Yuseong, Daejeon, 305-353, Republic of Korea

Keywords: Plant Level Framework, Spent Nuclear Fuel Reprocessing, Pyroprocess, Mass Balance, Discrete Event

Dynamic System.

Abstract: A plant level framework has been developed for a nuclear recycling facility. A plant level model generally

consists of multi-tiered models. The bottommost tier is a unit process model regarding electro-chemical

phenomenon. The middle tier is an operation model regarding mechanical handling of the process

equipment. The topmost tier is a systemic integration in the level of the plant. Even though a unit process

model is fundamental to build higher tier models it takes time to make a model with high fidelity. Therefore,

a different strategy for a plant level model building is suggested in this study. One of the important issues

that nuclear recycling process must consider is dynamic material flow, which could be done with the help of

a unit process model. However, from plant level aspect, it can be simply obtained from mass balance sheet

rather than understanding of electro-chemical behavior during process time. A plant level framework was

suggested to be able to include dynamic material flow even without a unit process model. Thus, a more

reliable unit process model can be added later selectively. The characteristic of the current framework was

addressed and evaluated for further improvement. The current version of the plant-level-framework could

provide many unforeseeable results which are difficult to obtain by intuition. Nevertheless, the next version

will include more function to provide various analyses linked with other nuclear related codes.

1 INTRODUCTION

Next generation nuclear fuel cycles require

innovative features such as an environmental load

reduction, safety, efficient recycling of resources,

nuclear proliferation resistance, economics, and so

on. From these viewpoints, a pyrometallurgical

processing of spent fuel is now considered as one of

the most promising options for future nuclear cycles

in Korea (Kim, 2006). KAERI has been developing

pyroprocess technologies, which could reduce the

increasing amount of spent nuclear fuel and

dramatically decrease the disposal load, through

recycling and destroying toxic waste such as the

long-life fission products in spent nuclear fuels (You,

2007).

Pyroprocessing technology has not been fully

demonstrated in terms of comercialization and

technology maturity. In order to navigate the right

direction of pyroprocessing technology development,

demonstration in an integrated facility is centainly a

tangible solution but is too costly and time

consuming to construct a fully integrated facility

including all unit process and remote handling

equipment. Therefore, technolgoy assessment and

breakthrough by modeling and simulation would be

preferable. Plant modeling and simulations are now

widespread among the manufacturing, semi-

conductor, steel and refinery industries. However,

they focus on layouts, assembling, automation and

remote control of the process flow.

Currently, there is niether commercialized nor

integrated pyroprocessing facility around the world.

KAERI is constructing an integrated demonstration

facility and thus expect to contribute to boost up

pyroprocessing technology and step toward

realization of spent nuclear fuel recyling.

Nevertheless, pyroprocessing technology is

confronted by many problems which are awaiting

solutions at the moment.

Expected potential benefits of modeling and

simulation in the field of nuclear reprocessing

system include the following: reduced cost of

process and facility development, optimized system

designs and reduce risk of material diversion.

Actually, modeling and simulation enhance

377

Jik Lee H., Il Ko W. and Soo Lee H..

Plant Level Framework for Material Flow in a Nuclear Reprocessing Facility.

DOI: 10.5220/0004056703770383

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 377-383

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

understanding of known systems, provide qualitative

and quantitative insights and guidance for

experimental work and produce qunatitative results

that replace difficult, dangerous or expensive

experiments (DePaoli, 2011).

The pyroprocessing contains various unit

processes and various types of nuclear materials that

flow in and out of those unit processes. It is a batch

type process in overall terms, i.e., reciept and

shipment of material among unit process, however,

unit process itself features continuous chemical or

electro-chemical process. Unit process may have a

different batch capacity and different processing

time. Also, there is feedback of output material on a

unit process into a prior unit process. In addition,

nuclear elements may take different routes as the

process goes on. Due to this complexity, it is

difficult to understand the dynamic behaviors of the

material flow in the pyroprocess. With this

background, this study was undertaken. Simple

material flow in the pyroprocess can be easily

understood by static mass balance. However, a

simple material flow based on the static mass

balance cannot give insight into any dynamic

behavior of the material flow because it cannot take

into account changes according to time and event.

An EXCEL-like software is widely used to

establish the static mass balance of the overall

process but it is very restrictive to implement a

dynamic material flow in the pyroprocess. In this

study, a modeling and simulation tool for discrete

event dynamic system (DES), ExtendSim was

utilized for the plant level framework of a dynamic

material flow. The pyroprocess was modeled as DES

in this work and then a dynamic material flow was

simulated under the framework.

2 R&D STATUS

2.1 The U.S.

Motivated by the challenges and needs in nuclear

energy systems that can be addressed bymodeling

and simulation, the Office of Nuclear Energy of the

U.S. Department of Energy hasarticulated a vision

for a Nuclear Energy Advanced Modeling and

Simulation (NEAMS) program.NEAMS is aimed

toward building on the success of recent programs in

advanced scientificcomputing, namely, ASCI and

SciDAC, with a focus on very different challenges.

Thesechallenges include the need for nuclear energy

systems to be licensed by regulators andmoving

advanced technologies out of the research

environment and into the hands of theengineers who

will design, build, and operate the new nuclear

energy systems. NEAMS will provide a

comprehensive solution and is organized into the

following five elements:

• Integrated Performance and Safety Codes (IPSC)

end-to-end codes to understand the detailed,

integrated performance of new nuclear systems

including the following: Nuclear Fuels, Reactor

Core & Safety, Separations and Safeguards, Waste

Forms and Near-Field Repositories.

• Fundamental Methods and Models

• Verification, Validation, and Uncertainty

Quantification

• Capability Transfer Enabling Computational

Technologies

Through the NEAMS-IPSC, the U.S. is devoting to

develop reprocessing plant level toolkit named

RPTk (Reprocessing Plant Toolkit), which uses open

source platform to accormodate legarcy codes

accross the U.S. (McCaskey, 2011). RPTk

implements a data flow architecture that is the

source of the system’s extensibility and scalability.

Data flows through physicochemical modules

sequentially, with each module importing data,

evolving it, and exporting the updated data to the

next downstream module. This is accomplished

through various architectural abstractions designed

to give RPTk true plug-and-play capabilities.

2.2 Japan

A decade ago, Japan developed an analysis code

(Okamura, 2002) using the object-oriented software

ExtendSim for the estimation of material balance for

the system design of the pyrochemical reprocessing

plants consisting of batch processes. This code can

also estimate the radioactivity balance, decay heat

balance and holdup, and easily cope with the

improvement of the process flow, and so on. The

study describes the outline of the code and

estimation of the material balance in the oxide

electrowining reprocessing system under

consideration of the solvent recycling time.

Howerver, it is difficult to find out current activity

with respect to modeling and simulation spent fuel

recyling facility in japan.

2.3 Korea

In order to analyze operational issues in a

pyroprocessing head-end facility, discrete event

modeling approach was applied (Lee et al., 2009).

Also, a code development study on the dynamic

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

378

material flow in the integrated pyroprocess was

carried out (Lee et al., 2011) under the discrete event

system environment. This paper addresses the plant

level framework in detail including the previous

dynamic material flow study.

3 REQUIREMENT

3.1 Nuclear Facility

A nuclear facility deals with radioactive material and

the recycling facility can have various types of

material since nuclear spent fuel consists of various

nuclear fissile elements. Specifically, integrated

pyroprocess facility has a lot of unit process

equipment, remote handling device and various

utility, which need to be appropriately maintained

and repaired for machine failure.

Receipt and shipment of nuclear material and

remote operation of process equipment are

considerately designed in terms of safety and

efficiency. Also, safeguards study to prevent nuclear

material diversion is critical issue in design stage.

Current version of plant level framework does not

include safeguards module, but later version will

consider including it.

3.2 Facility Code Requirement

Simulation code for pyroprocessing facility is

required to have the following features:

1. Modularity

Modularity means re-useable code. Some libraries or

blocks can be frequently re-useable within a plant

model. For example, dynamic mass balance

calculation algorithm is needed to calculate

processed quantity in any unit process during

simulation.

2. Flexibility

Flexibility means the code can be modifiable in easy

way. For example, if more reliable unit process has

been built, it can be replaced with old one without

many modifications of code. Also, additional

function or module could be attached in a way that

main framework or top tier model does change

minimally or does not change by taking interface

with additional module into consideration.

3. Database management

Database management is very important issue in

terms of nuclear element management. Recycling

facility starts with spent nuclear fuel having many

element, which changes its form, radioactivity and

amount according to process flow. There are three

types of data as follows: input data, output data, and

log data. Input data are for example, changeable

process conditioning parameters. It influences

simulation results. Output data can be simulation

results related data, for example, product amount,

buffer accumulation and waste generation. Data

logging is important to keep and store time

dependent information, and see and analyze those

after simulation. For example, status of unit process,

operation records, resource utilization and all output

data can be log data.

4. Interface with other platform code

There exist many legacy codes developed in other

software platforms. Specifically, unit process model

has been generally generated by using other

conventional platform such as C/C++, FORTRAN,

and matlab according to modeller’s preference.

Therefore, integration of different codes could be an

issue on plant-level-code development.

5. Reliability enhancement strategy

In order to enhance model and well estimate reality,

model validation must be performed with a lot of

experimental data. Throughout comparison with

various real cases, model could be enhanced.

Therefore, validation can be easily carried out by

visualization of analysis results.

3.3 Plant-level Code Configuration

Plant-level-model includes all lower models together

with various modules. The unit process model is

surrounded by unit operation model describing

feeding and takeout of material in that process and

then material streams among unit process are

completed by integrated operation model which can

describe the shipment of material.

Also, in the integrated modelling stage, resources

such as remote handling device, human, vessel and

storage are allocated to unit process according to

necessity and withdrawn after the task is finished.

All items taken out of and fed into unit process are

treated in the unit of batch capacity of unit process.

If two sequential unit processes have different batch

capacity, the item taken out of the first unit process

has to be changed to meet the batch capacity of the

next unit process. Material streams indicate where

items must flow into and thus connectors and lines

must be designed according to material streams.

Discrete event modelling might handle the above

issues without difficulty. The plant-level-model also

has to include three functions: analysis, database

management and visualization. They could be

modularized and developed in many ways. For

Plant Level Framework for Material Flow in a Nuclear Reprocessing Facility

379

example, DB can be remotely far from ExtendSim

and just linked with ExtendSim.

4 PLANT LEVEL MODEL

4.1 3-tiered Modelling Architecture

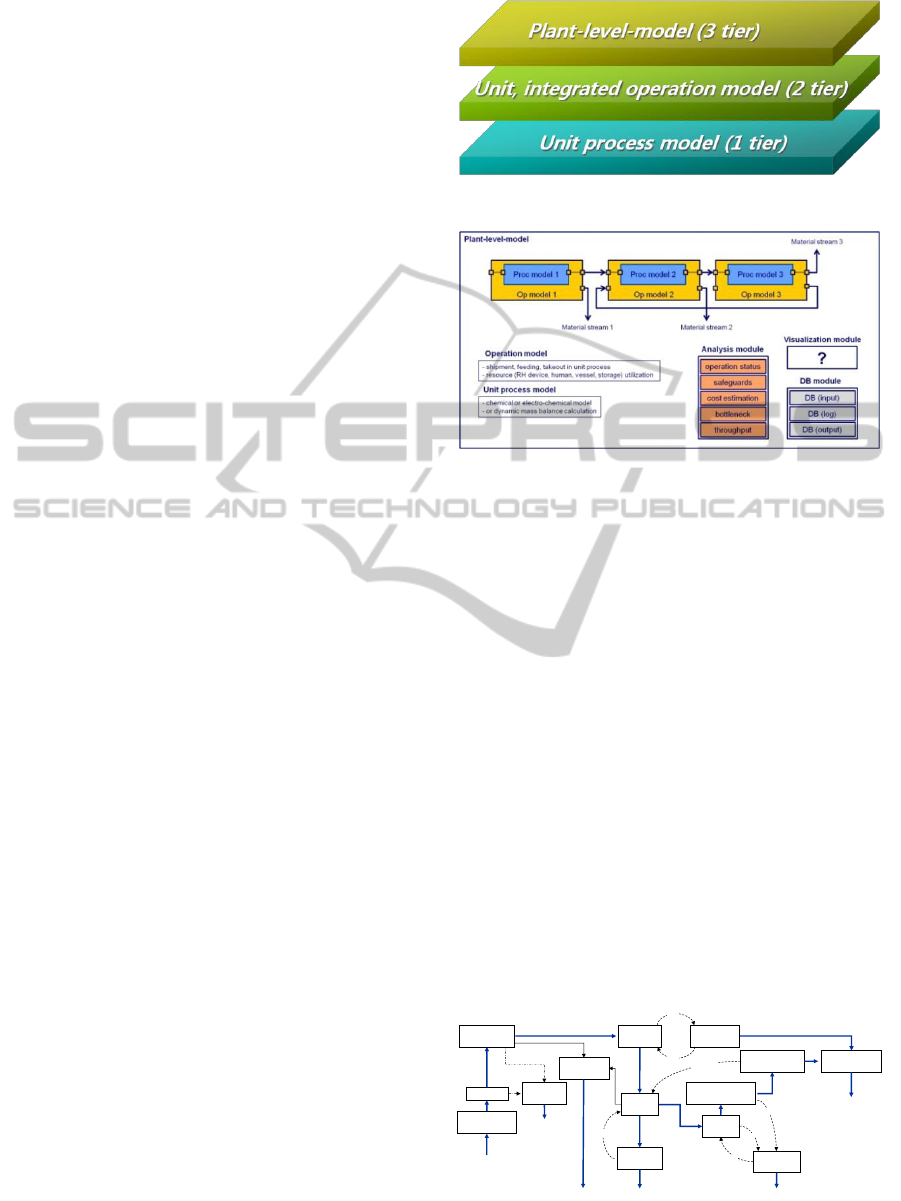

In order to build plant-level-model, 3-tiered code

development architecture was invented in KAERI.

The bottom tier is unit process modeling which

includes electro-chemical model influencing output

chemical composition. The middle tier includes unit

and integrated operation model which describes

operation behavior such as feeding, transporting and

other mechanical operations from unit or integrated

process ascpect, resptectively. The top tier is the

plant-level-model, which must have various analysis

modules, and DB module for SNF and isotope

inventory. It also have to show the results,

intuitively through well designed visualization

module.

4.2 Basic Framework

Without reliable unit process model, it is too

difficult to build upper tier model. Currently

electrochemical process is not well described by

model and must be enhanced further. It is alike

wasting time to wait until the reliable unit process

model is built. Furthermore, most part of the middle

and top tier model can be built without the unit

process model. Given feeding material composition

and its amount, unit process model presents

generally output composition of element after

electrochemical reaction. Noticing that expected

values of output composition could be set by target

values in an equilibrium mass balance sheet, the

calculation of dynamic mass balance per batch

operation in unit process might be alternative of unit

process model. Even though equilibrium mass

balance means total input and output mass balance

in each unit process at a certain time, it can be

broken down by unit of each batch operation

capacity of unit process according to each batch time

and it can be made to present dynamic mass balance.

The current version of plant level framework was

tested by using dynamic mass balance calculation

algorithm without unit process model. However, the

framework could selectively include the unit process

model or dynamic mass balance calculation

algorithm when the reliable unit process model is

prepared.

Figure 1: Three tiered code development architecture.

Figure 2: Configuration of plant-level-framework.

4.3 Dynamic Material Flow

Pyroprocess consists of a dozen of unit process and

various material streams among them as shown in

Figure 3. Material streams in pyroprocess are

classified into two categories: nuclear spent fuels

and two kinds of salt (LiCl and LiCl-KCl). First

feeding material of pyroprocess is spent nuclear fuel

from nuclear reactor in the form of assembly and

final product is volatile FP (fission product), metal

waste, ceramic waste, uranium metal ingot and TRU

(transuranium) for fast reactor fuel fabrication.

Every time process proceeds to next step, many

things (processed mass, buffer accumulation, the

number of batch operation, etc.) are changed

according to time. In order to capture such dynamic

characteristic related to material flow, discrete event

based dynamic mass balance calculation (Lee et al.,

2011) is needed in case where a target mass balance

is set by equilibrium state at a specific instance in

time.

Figure 3: Pyroprocess material streams.

U metal ingot

Chopping

Electro-

winning

Salt (LiCl+KCl)

Purification

Cathode

Processing

Salt (LiCl)

Purification

Oxide

Reduction

Cd

LiCl+KCl

LiCl

LiCl+KCl

LiCl

Cd

Distillation

Cd

Residual Actinide

Recovery

Cd

PWR SF

Assembly

Ceramic Waste

Processing

Disassembly

/rod extraction

Electro-

refining

SFR Fuel Fabrication

Metal waste

processing

Metal Waste

Ceramic

Waste

Off-Gas

Treatment

Volatile FP

Decladding

/Voloxidation

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

380

The following equation addresses the processed

amount of mass in process

given the voloxidation

equivalent batch capacity of process

and the

amount of shipment according to path from process

to process

.

where

: the processed amount of mass in process

,

and it depends on event.

: the voloxidation equivalent batch capacity

in process

, which means the mass of

material that the voloxidation process must

treat in order to supply the process

with

feed material for one batch of the process at

full capacity.

: the voloxidation equivalent batch capacity

in voloxidation process, i.e., voloxidation

batch capacity.

: the actual processed mass per batch in the

voloxidation process, which is equal or less

than

.

: the equilibrium processed mass in the

voloxidation process, which is the

processed mass by a certain time (generally,

one year).

: the number of shipment of product from

process

to process

and it depends on

event.

: the equilibrium mass transferred according

to path from process

to process

by a

certain time (generally, one year).

In the above equation, the voloxidation equivalent

mass is convenient when the operational relationship

among process is needed to define. The reference

process where equivalent mass is calculated can be

randomly selected but the preceding process is

preferred.

In the equation, by the law of conservation of

mass, the following property can be induced.

where

: the amount of shipment from process

to process

by a specific instance in

time, i.e. by the time when event

happens.

: the amount of hold-up remains in the

process

without leaving for the process

.

The above equation means the feeding and leaving

amount are the same without hold-up in unit process

in equilibrium state and it is the processed amount in

that process. However, before the equilibrium state,

the processed amount in unit process is equal to a

total of feeding material but not equal to a total of

leaving material.

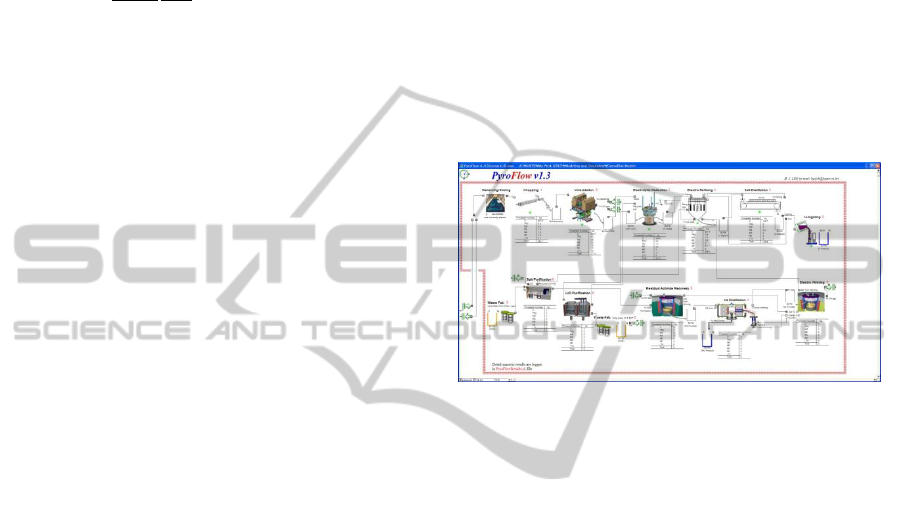

Figure 4: Top window of pyroprocessing plant model.

5 RESULTS AND DISCUSSIONS

5.1 Top Model Design

Figure 4 presents the top model just embrassing

operation model and dynamic mass balance

calculation algorithm. It shows basic information of

material flow by means of visualizaiton through

animation which indicates text and picture

information changes according to time.

Multi-tiered model architecture might be simply

represented on the model by hierarchy. Complex

details corresponding to lower tiers could be hidden

and on top window only a little information might be

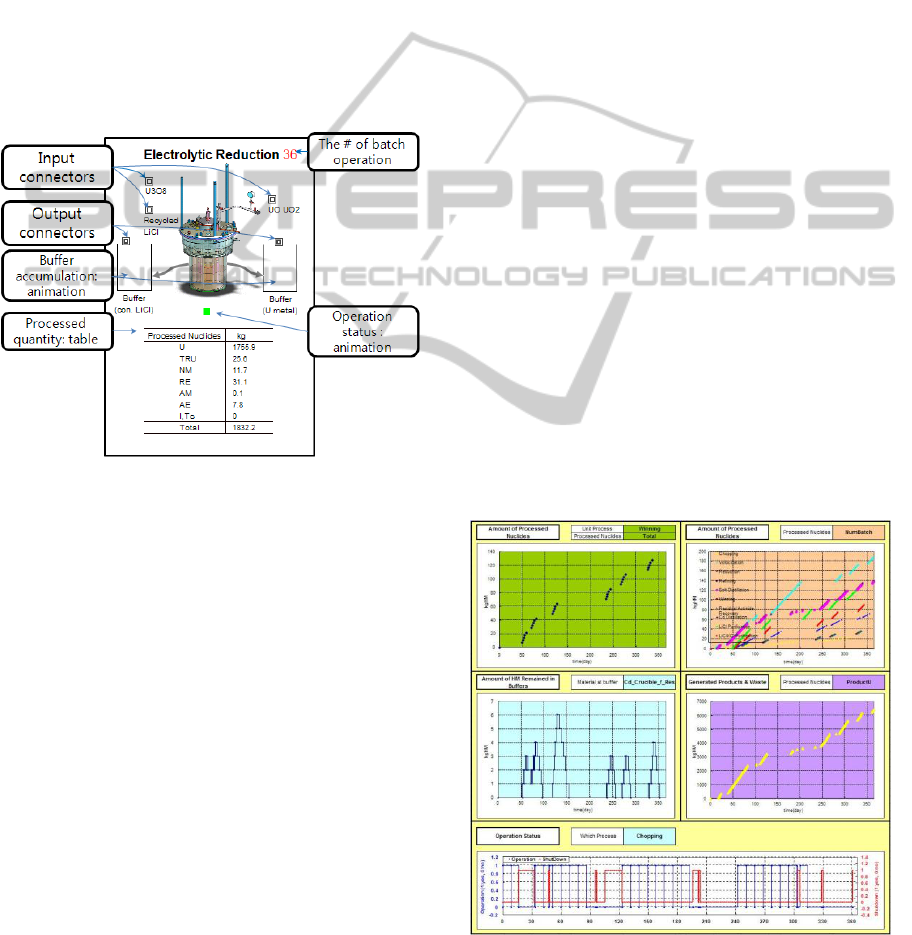

displayed. For example, electrolytic reduction

process wants U

3

O

8

powder and recycled or fresh

LiCl salt as feeding material, and pushes output

material into temporary buffers every batch

operation. Basic information that unit process block

includes is input connectors, output connectors,

buffer accumulation, processed quantity, the number

of batch operation and operation status as shown in

Figure 5.

The input and output connectors with names

indicate types of the feeding material and output

product, respectively. The buffer might be real or

Plant Level Framework for Material Flow in a Nuclear Reprocessing Facility

381

imaginary but most pyroprocessing unit is operated

in batch type so it is important to have sufficient

storage between unit processes to prevent being

stuck. The buffer accumulation is animated with the

level of tank. The table below the picture icon

indicates processed quantity of grouped element

which changes dynamically. On the right side of the

process name, the number of batch operations is

displayed up to now, which is also changed

dynamically according to event. The last information

of unit process block is operation status, which

classified into three kinds: in operation, in

breakdown and out of order. The above information

is much enough to deliver what happens in the unit

process to user during simulation.

Figure 5: Configuration of unit process block on the plant

level top window.

However, detailed numeric results obtained from

simulation might be stored in external database

management software such as EXCEL, ACCESS

and SQL. Specifically, log data describing history

statistics for simulation time should be stored in the

above mentioned DB SWs. Also, numeric results

must be shown in easy ways by using charts and

graphs. The more data are generated, the greater care

should be devoted to visualization in consideration

of what users should look at and how efficiently

results could be shown.

5.2 Function of Current Version

For more realistic simulation, it is assumed that unit

process is possible to be out of order. Besides, many

factors are assumed since real facility has not been

developed. Process time, failure rate, batch capacity,

the number of equipment and the arrival of spent

nuclear fuel are assumed on the basis of

experimental experience or achievable goal based on

the current level of technology, otherwise, set by

design goal.

In the current version of framework, results are

exported to EXCEL and displayed on charts in real

time since it is fast enough to treat limited data.

However, the more data might require more efficient

DB management SW other than EXCEL. Figure 6

shows results able to be displayed in the current

version. The processed mass of grouped element or

total heavy metal of spent fuel is displayed being

classified by unit process. The number of batch

operations tells us which process is late determining

process or bottleneck process during simulation time.

The buffer accumulation indicates that the facility

has a minimum size of buffer storage to temporarily

accommodate product to be sent to the next process.

Also, product and waste mean final output in the

pyroprocess, which will be sent to metal fuel

fabrication facility for recycling and to an interim

storage facility for disposal.

The framework will be more modularized in the

next version to include much more control function

and information and to be simplified in the top

window. Also, material flow will be broken down

from element level into isotope level, which means

over 1,000 isotopes must be tracked according to

time and event. In addition, the plant-level

framework will be enhanced to be linked with other

nuclear related codes for decay heat, isotope

composition, criticality and radioactivity calculation

if necessary. Regarding DB, restructuring might be

needed in order to manage more data at high speed.

Figure 6: Analysis results able to be obtained from current

version of plant level model.

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

382

6 CONCLUSIONS

Plant-level framework consisting of 3-tiered model

with some functional modules was suggested for

pyroprocessing facility. Current version of

framework includes basic function for material flow

analysis. One of important characteristic in the

current version is that dynamic mass balance

calculation is possible even without unit process

model. It can make us estimate integrated material

flow in the pyroprocessing facility. The plant model

framework will be improved to satisfy facility code

requirement and to provide various analysis linked

with nuclear related codes. Modelling and

simulation for pyroprocessing facility is expected to

save construction cost and reduce design error,

finally devote generation of design requirement for

engineering scale or commercialized scale facility.

ACKNOWLEDGEMENTS

This work was supported by Nuclear Research &

Development Program of National Research

Foundation of Korea (NRF) funded by Ministry of

Education, Science & Technology (MEST).

REFERENCES

DePaoli, David, 2011. Modeling and Simulation of

Nuclear Fuel Recycling Systems, Short Course of

“Introduction to Nuclear Chemistry and fuel cycle

separations.”

ExtendSim, http://www.extendsim.com

Kim, E. H., 2006. Current status on development of P&T

in Korea, In: Proceedings of the 9th Information

Exchange Meeting on Actinide and Fission Product

Partitioning & Transmutation, Nimes, France.

Lee, H. J. et al., 2009. Discrete event system simulation

approach for an operation analysis of a headend

process facility. Nucl. Eng. Technol. 41, 739-746.

Lee, H. J. et al., 2011, Discrete event dynamic system

(DES)-based modeling for dynamic material flow in

the pyroprocess, Annals of nuclear energy, 38, 860-

875.

McCaskey, A., Billings, J., Almeida, V., 2011. The

nuclear energy advanced modelling and simulation

safeguards and separations reprocessing plant toolkit,

ORNL/TM-2011/261.

Okamura, N., Sato, K., 2002, Computer code system for

the R&D of nuclear fuel cycle with fast reactor. IV.

Development of an object-oriented analysis code for

estimation of the material balance in the pyrochemical

reprocessing process, Cycle system technical report, 3,

1-10.

You, G. S. et al., 2007. Status of technology and policy of

nuclear spent fuel treatment in advanced nuclear

program countries and relevant research works in

Korea. Journal of the Korean Radioactive Waste

Society, 5, 339-350.

Plant Level Framework for Material Flow in a Nuclear Reprocessing Facility

383