SAFE CONTROLLERS DESIGN FOR HIBRID PLANTS

The Emergency Stop

Eurico Seabra and José Machado

Mechanical Engineering Department / CT2M, Enginnering School, University of Minho, 4800-058 Guimarães, Portugal

Keywords: Safe Controllers, Emergency Stop, GEMMA, Hybrid Plants.

Abstract: This paper presents and discusses a case study that applies a global approach for considering all the

automation systems emergency stop requirements. The definition of all the functioning modes and all the

stop tasks of the automation system is also presented according the standards EN 418 and EN 60204-1. All

the aspects related with the emergency stop are focused in a particular way. The proposed approach defines

and guarantees the safety aspects of an automation system controller related with the emergency stop. For

the controller structure it is used the GEMMA formalism; for the controller entire specification it is used the

SFC and for the controller behavior simulation it is used the Automation studio software.

1 INTRODUCTION

This work is inserted in a bigger project being

developed at the School of Engineering of

University of Minho (Portugal) - involving four

Departments of the School: the Mechanical

Engineering Department, the Electronics

Department, the Informatics Department and the

Industrial Engineering Department - related with

application of several techniques in order to obtain

safe controllers for Automation Systems.

The same team of this project has developed

another project, before this one, where it were

studied aspects relied to plant modeling of timed

systems and its influence on the Simulation and

Formal Verification of Automation Systems

Controllers (Machado et al, 2008), (Seabra et al,

2007), (Machado and Seabra, 2008).

In the actual study it is intended to study and

develop some techniques in order to obtain safe

controllers for hybrid plants. The first results are

presented on this paper where it is presented the

aspects relied with the emergency stop of

automation systems and all the aspects to considerer

when there are defined the functioning modes and

the stop tasks of an automation system (EN 418).

Also, the controller, in general, will need to comply

with Safety of machines requirements (EN 60204-1).

For the Safety controllers design, there are

applied some techniques like synthesis techniques

(Ramadge and Wonham, 1987) or analysis

techniques (Frey and Litz, 2000) in order to be

accomplished the desired specifications for the

automation system behavior. Between these

techniques there are considered, in more detail, in

this paper the analysis techniques.

Considering some aspects and techniques inside

of the analysis techniques group the most important

are: Identification (Klein, 2004), Simulation (Baresi,

2002) and Formal Verification (Rossi, 2004). This

approach is based on Simulation Techniques and it

is considered, on the first hand, a discrete controller

and the hybrid plant are modeled as being discrete.

This simplification will allow us to obtain, faster and

with the same rigor, some results relied with the

emergency stop behavior for the automation system.

The Emergency Stop is one of the most

important aspects attending to the safety of people,

goods and equipments that interact with the

automation system.

In order to obtain safe controllers, it must obey at

some rules (EN 418, 1992), (EN 60204-1, 1997):

- a fault in the software of the control system

does not lead to hazardous situations;

- reasonably foreseeable human error during

operation does not lead to hazardous

situations;

- the machinery must not start unexpectedly;

- the parameters of the machinery must not

change in an uncontrolled way, where such

change may lead to hazardous situations;

172

Seabra E. and Machado J.

SAFE CONTROLLERS DESIGN FOR HIBRID PLANTS - The Emergency Stop.

DOI: 10.5220/0002249501720177

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-674-001-6

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

- the machinery must not be prevented from

stopping if the stop command has already

been given;

- no moving part of the machinery or piece

held by the machinery must fall or be

ejected;

- automatic or manual stopping of the moving

parts, whatever they may be, must be

unimpeded;

- the safety-related parts of the control system

must apply in a coherent way to the whole

of an assembly of machinery and/or partly

completed machinery;

As guarantee that the developed controller will

react always according the expected behavior, it is

only necessary to model the controller and the plant

as being discrete. Indeed, our system has a hybrid

plant, but the properties of behavior that we intend

to guarantee, for our system, are only related with

discrete behavior.

For more complex properties – dealing with

hybrid behavior of the automation system – it will be

necessary to model the controller and the plant as

hybrid. This will be done on a next step in this

complex research project, using formalisms and

tools well adapted for these tasks, like, for instance,

Stategraphs (Otter et al, 2005) to model the

controller and Modelica programming language

(Elmqvist and Mattson, 1997) to model the plant.

On this study, presented on this paper, we use the

GEMMA (ADEPA, 1992) for the controller

structure, the SFC (IEC 60848, 1998) as controller

specification formalism and the Automation Studio

software (Automation Studio, 2004) for the

simulation tasks of the controller specification. With

this set of formalisms and tools we demonstrate that

it is all we need for guarantee all the desired

behavior for the automation system when the

emergency stop command is actuated.

In this first approach it is intended to conclude

about the more important behavior properties related

with the emergency stop of the automation system

and the use of the formalisms, and tools, previously

described (GEMMA, SFC and Automation Studio)

allow us to obtain the desired results in a fast and

expedite way.

One of the limitations of this first approach is

that the hybrid plant is model as discrete, but this

simplification allows the fast obtaining of results

related with discrete desired behaviors, being the

efforts of modeling more simple and fast.

As we presented before, this step on a more

complex approach is only the first step considered in

order to guarantee the desired behavior in case of

occurrence of the “Emergency” command.

To accomplish the proposed goals, in this work,

the paper is organized as follows. In Section 1, it is

presented the challenge proposed to achieve in this

work. Section 2 presents the case study plant related

with an automatic system for filling and

encapsulating bottles. Further, it is presented the

base controller specification and the total controller

structure that includes the emergency stop. Section 3

is exclusively devoted to the emergency stop

techniques discussion. Section 4 presents and

discusses the emergency stop adopted solution and

the total controller specification. Finally, in Section

5, the main conclusions and some future directions

to follow in this project that is now starting at the

School of Engineering of University of Minho.

2 SYSTEM DESCRIPTION

The case study corresponds to an automatic machine

of filling and encapsulating bottles (Fig. 1). This is

divided in three modules, transport and feeding,

filling and encapsulating. To increase the

productivity, is used a conveyor with several alveoli

for the bottles to allow the operation in simultaneous

of the three modules.

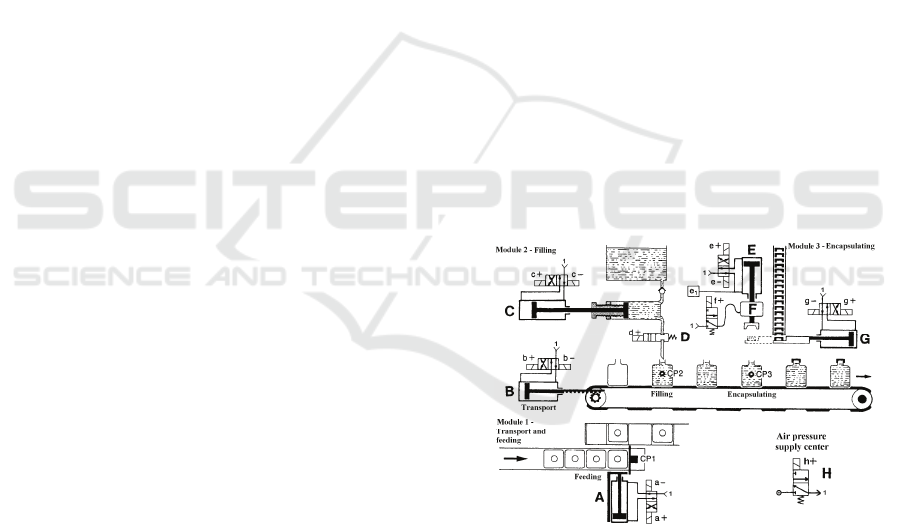

Figure 1: Case study plant.

The transport and feeding module is constituted by a

pneumatic cylinder (A) that is the responsible for the

bottles feeding of the conveyor and another

pneumatic cylinder (B) that executes the

step/incremental advance of the conveyor.

The filling module is composed by a volumetric

dispenser, a pneumatic cylinder (C) that actuate the

dispenser and an on/off valve (D) to open and close

the liquid supply.

SAFE CONTROLLERS DESIGN FOR HIBRID PLANTS - The Emergency Stop

173

The encapsulating module has a pneumatic cylinder

(G) to feed the cover, a pneumatic motor (F) to

screw the cover and a pneumatic cylinder (E) to

advance the cover. The cylinder (E) moves forward

until the existent cover, it retreats with this cover

during the retreat of (G), continuously it moves

forward again with rotation of the motor F to screw

the cover.

2.1 Base Controller Behaviour

Specification

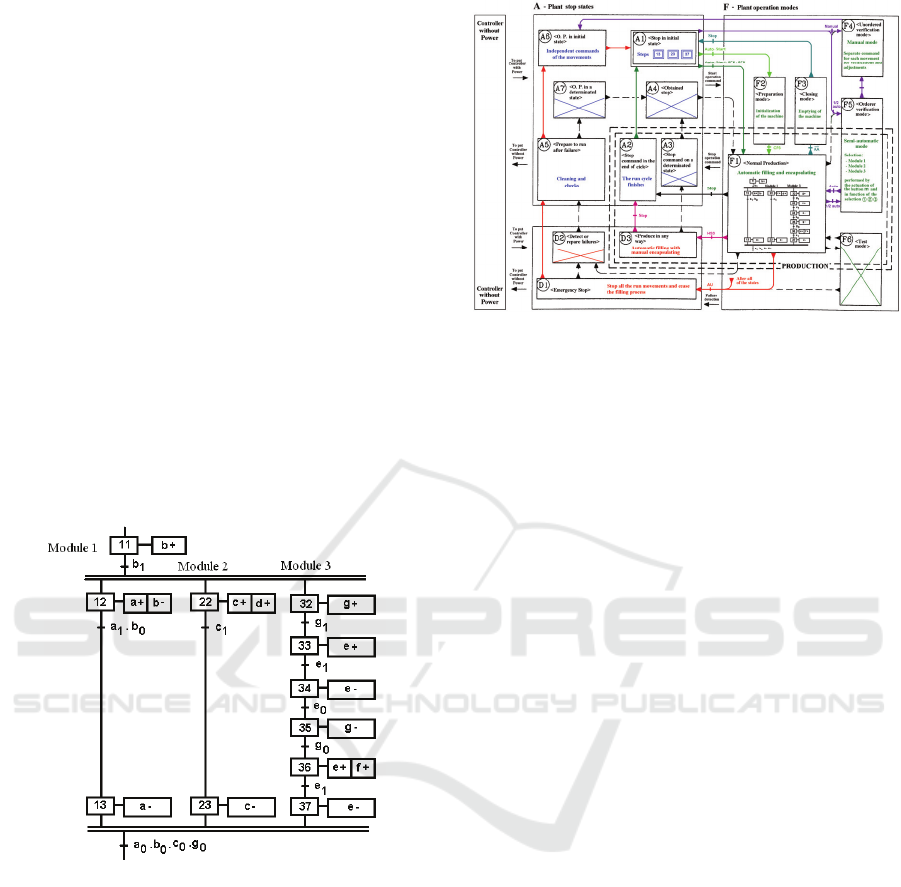

Figure 2 shows the base SFC of the system

controller, corresponding only to the "Normal

production” mode. The basic sensors involved are:

two end-course-sensors for each cylinder (example:

cylinder A, sensor a0 and a1, respectively, retreated

and advanced) and a sensor of pressure e1, which

detects the point of contact/stop of the cylinder E in

any point of its course.

The valve D and the motor F don't have position

sensor because they are difficult to implement.

Figure 2: Base SFC specification controller.

On the other hand, in order to obtain the total

SFC controller, which includes all the operation

modes required for the correct operation of the

system, was used the graphic chart of GEMMA

because it allows the definition of the run and stop

machine tasks.

2.2 Total Controller Behaviour

Structure

Figure 3 shows the GEMMA graphic chart

developed for the case study presented. The

considered tasks are described to proceed:

Figure 3: GEMMA of the plant controller.

A1 – The task A1 "Stop in the initial state"

represents the task of the machine represented in the

Figure 1.

F1 – Coming of the task A1, when it occurs the

start command of the machine, it happens the change

for the task F1 "Normal production” (Filling and

automatic encapsulating) with the consequent

execution of base SFC presented in the figure 2.

A2 – When it happens the stop command of the

machine the run cycle finishes in agreement with the

condition described at the task A2 “Stop command

in the end of cycle”.

F2 – When the machine is "empty" (without

bottles) it is necessary to feed bottles progressively,

being the machine ready to begin the normal

production (task F1) when it has bottles in the

conveyor positions of the production modules 2 and

3, respectively. This operation is defined by the task

F2 “Preparation mode”.

F3 – The "Closing mode" of the task F3 allows

the reverse operation, that is, the progressive stop of

the machine with the exit of all of the bottles

(emptying of the machine).

D3 – When the encapsulating module is out of

service it can be decided to produce in any way, that

is, to perform the bottle filling in an automatic way

and posterior manual encapsulating, this is main

purpose of the task D3 "Production in any way".

D1 – In the case of a situation emergency to

occur, the task D1 “Emergency stop" is executed.

This stops all the run actions and closes the filling

valve to stop the liquid supply.

A5 – After the emergency stop (task D1), the

cleaning and the verification are necessary: this is

the purpose of the task A5 "Prepare to run after

failure“.

A6 – After the procedures of cleaning and

verification they be finished becomes necessary to

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

174

perform the return to the initial task of the machine,

as described at the task A6 "O.P. (operative plant) in

the initial state".

F4 – For example, to the volume regulation of

the bottle liquid dispenser and adjustment of the

bottles feeder, a separate command for each

movement is required, according to the task F4

"Unordered verification mode”.

F5 – For detailed operation checks, a

semiautomatic command (only one cycle) it is

necessary to check the functioning of each module:

task F5 "Ordered verification mode".

To be possible the GEMMA evolution becomes

necessary existing transition conditions for the run

and stop operation modes, described previously.

These transition conditions will be accomplished

using GEMMA, as presented to proceed:

- To allow the progressive feeding demanded in

the preparation way (F2) and the progressive

discharge required in the closing way (F3) it will be

necessary to consider sensors that detect the bottles

presence under each one of the modules 1, 2, 3,

respectively, CP1, CP2, CP3 (Fig. 1);

- Also, it will be necessary a command panel that

supplies the transition conditions given by an

operator (Fig. 4).

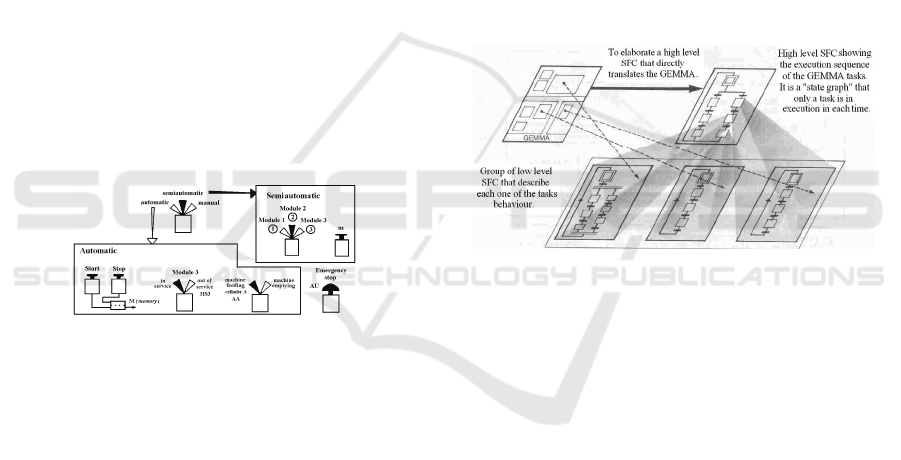

Figure 4: Command panel of the system controller.

In the command panel, there is a main switch

that allows selecting the “automatic”,

“semiautomatic” and “manual” operations modes.

To the "automatic" option correspond:

- Two buttons "start" and "stop" whose action is

memorized in memory M;

- A switch HS3 to put "in service" or "out of

service" the module 3;

- A switch AA to control the bottles feeding

permission (cylinder A), to allow the emptying of

the machine.

These switches/buttons, and sensors CP1, CP2

and CP3, are the transition conditions of the tasks

A1, F1, F2, F3, A2 and D3, as shown in Figure 3.

The "semiautomatic" option corresponds to the

task F5 "Ordered verification mode", that allows

with the actuation of button (m), to check one cycle

operation of each modules, selected by the

"semiautomatic" switchc,d, or e.

The "manual" option corresponds to the tasks F4,

A5 and A6, which required a separate command

from each movement using a direct command on the

directional valves.

Finally, the AU button (Emergency stop) allows

pass to task D1 starting from all of the tasks.

The implementation of total controller's

specification, based on GEMMA presented in figure

3, it can be realized using the following two

alternative methods:

- Multiple SFC – develop one SFC for each task;

- Single SFC – develop one SFC for all tasks.

The multiple SFC methodology is represented in

figure 5, it includes a high level SFC that translates

the GEMMA (main routine) and multiple SFC that

correspond to each task (subroutines).

On the other hand, the single SFC method

corresponds to the implementation of all GEMMA

tasks behaviour in a total SFC. This was the method

used in the presented case study (see section 4).

Figure 5: GEMMA implementation with multiple SFC.

3 EMERGENCY STOP

The emergency stop must always change the

controller task and it should be obligatorily available

in any state of the SFC controller.

The types of emergency stops are divided in two

main groups:

- Without emergency sequence - the actuation of

the emergency button stops the system/automatism

through the inhibition of the outputs and/or for stop

the evolution of SFC.

- With emergency sequence - the actuation of the

emergency button starts a particular predefined

procedure.

3.1 Without Emergency Sequence

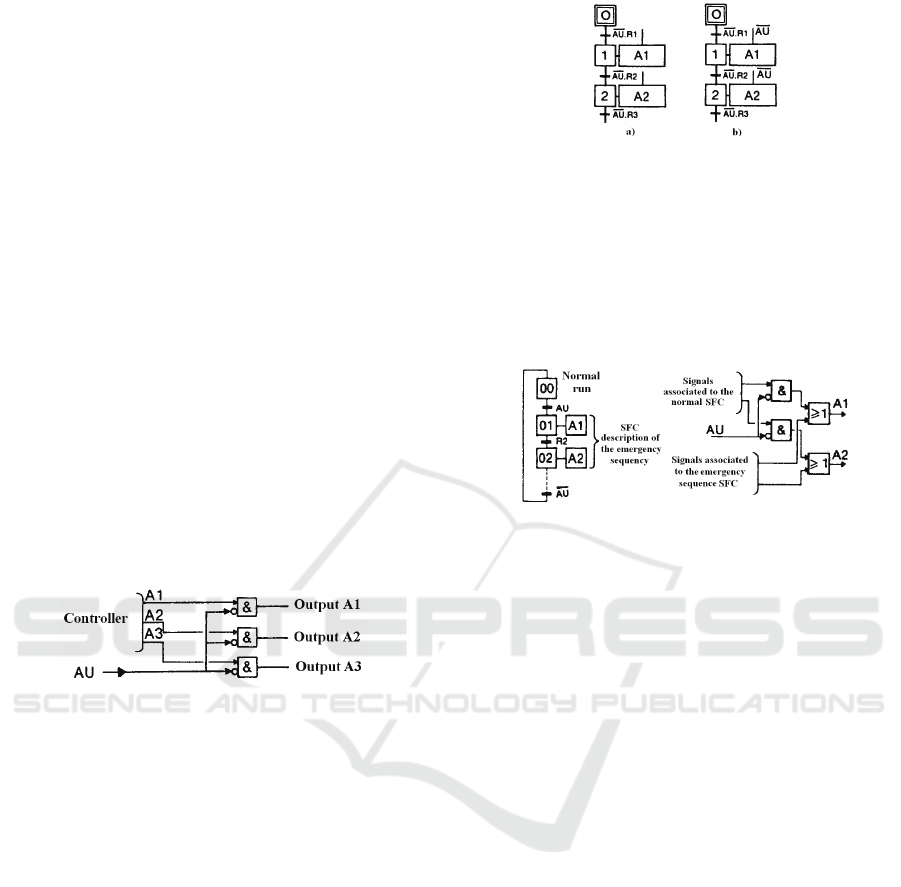

The emergency without emergency sequence can be

performed in three alternative modes:

- Outputs inhibition;

- Evolution stop,

SAFE CONTROLLERS DESIGN FOR HIBRID PLANTS - The Emergency Stop

175

- Outputs inhibition and evolution stop.

In the case of outputs inhibition the actuation of

emergency button doesn’t stop by itself the

evolution of the SFC controller, but it inhibits the

outputs associated to their stages, as shown in the

figure 6. The outputs eventually ON (state 1) they

are turn OFF (state 0), as well as, usually the

evolution of SFC is stopped by the non fulfilment of

the receptivity’s.

This can be obtained through the insert of

inhibition functions in the interface with the machine

plant. In this case, after the occurrence of an

emergency stop, the actuators command should be

particularly well studied in agreement with the type

of expected response.

For instance, for the cylinders directional valves:

- One stable state valve (single control with

spring return), if it be demanded a cylinder return for

a given position.

- Two stable state valve (double control), if it be

demanded a stop at the end of the cylinder

movement.

- Valve with three positions (double control and

spring return), if it be demanded a cylinder stop in

the actual position.

Figure 6: Functional diagram of outputs inhibition.

In the other hand, in the case of evolution stop

the condition AU is present in all of the SFC

receptivity’s (Fig.7a). With the actuation of

emergency button AU, no receptivity can be

validated and, this way, the controller SFC cannot

steps forward. With the AU shutdown a new cycle

evolution is allowed.

It is of highlighted that in this situation, the

outputs associated to the active stages stay validated.

This way, the start movements can continue, which

be able to result in dangerous situations and/or to get

to a situation that originates a future blockade of the

SFC evolution.

Finally, also it is possible to use in simultaneous

the two described types of emergency stop without

emergency sequence, outputs inhibition and

evolution stop (Fig. 7b). This situation is the more

used in practice, when if it doesn't turn necessary the

use of an emergency sequence. Seen that has the

advantage of allowing, after the emergency button

shutdown, the pursuit of the evolution of the system

starting from the same instant in that it was stopped.

Figure 7: a - Evolution stop; b - Evolution stop and

outputs inhibition.

3.2 With Emergency Sequence

This type of emergency implies the introduction of

an emergency sequence. Through the activation of

the emergency button AU an emergency sequence

can be added to the normal run SFC (Fig. 8).

Figure 8: Introduction of an emergency sequence.

4 EMERGENCY STOP ADOPTED

SOLUTION

The emergency stop adopted for the case study

presented was obtained according the standards EN

418 and EN 60204-1.

According to the behaviour of the case study was

selected the emergency stop with emergency

sequence. The considered requirements that should

be accomplished by the emergency sequence are:

- Stop all of the movements;

- Stop the filling operation.

To obtain these procedures it was crucial the

selection of the type of the directional valves

appropriate to accomplish in simultaneous the

requirements of the emergency stop and the plant

behaviour.

The directional valves specifications used were

the type of control (single solenoid control with

spring return or double solenoid control) and number

of ways/ports.

The first security requirement referred, related

with the stop of the movements, was obtained by

stopping the air compressed supply to the directional

valves of the cylinders A, B, C, E, G and of the

motor F. For that, as shown in figure 1, the air

supply will be centralized and controlled through a

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

176

directional valve 3/2 way normally closed with

spring return (H).

The second security requirement, related with

the stop the filling operation, was performed through

the turn OFF of the filling directional valve 2/2 way

normally closed with spring return (D).

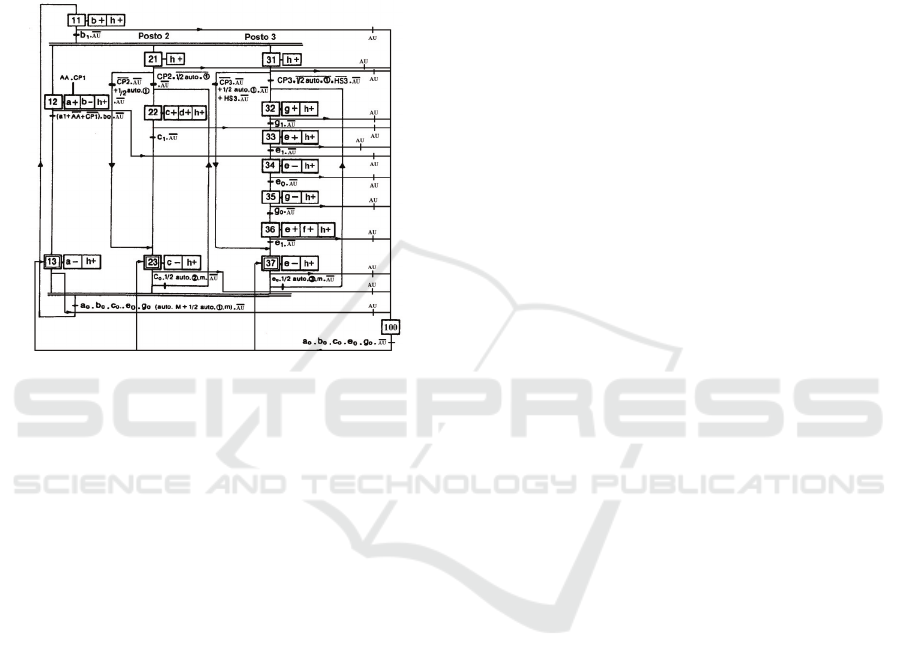

The figure 9 shows the total controller SFC

specification based on the GEMMA implementation

with the single SFC method (see section 2.2).

Figure 9: Total SFC controller specification with

emergence sequence.

All the controller specification, presented on the

previous figure, was simulated on Automation Studio

Software. The obtained results leaded to the conclusions

that all the requirements defined on the Emergency Stop

Standards, were accomplished.

Further, the specification was translated to Ladder

Diagrams according to the SFC algebraic formalization

and implemented on a Programmable Logic Controller

(PLC) adopted as the controller physical device. This part

of the developed work is not detailed on this publication.

5 CONCLUSIONS

It was presented, on a systematic way, the adopted

techniques for the emergency stop behavior

specification of automation systems.

The ways to translate the GEMMA graphical chart

to the low level specification was also presented and

discussed.

The standards (EN418, EN60204-1) related with the

stop emergency specifications were considered and

all the requirements were accomplished.

The obtained results, by simulation with Automation

Studio software, show that the adopted approach is

adequate.

Further work will be devoted, in one hand, to the

application of formal methods to verify some

important system’s behavior (taking into account the

discrete behavior of the system) and, in other hand,

the application of modeling techniques for hybrid

systems and respective tools for simulation and

formal verification.

REFERENCES

ADEPA, 1992. GEMMA (2nd Edition) – Guide d`Étude

des Modes de Marches et d`Arrêts.

Automation Studio, 2004. Famic Technologies inc.,

Automation Studio 5.0,

http://www.automationstudio.com.

Baresi L., Mauri M., Pezzè M., 2002. PLCTools: Graph

Transformation Meets PLC Design. Electronic Notes

in Theoretical Computer Science, Vol. 72, No. 2.

Elmqvist E., Mattson S., 1997. An Introduction to the

Physical Modelling Language Modelica. ESS'97.

Passau, Germany.

EN 418, 1992. Safety of machinery. Emergency stop

equipment, functional aspects. Principles for design.

European Standard.

EN 60204-1, 1997. Safety of Machinery - Electrical

Equipment of Machines - Part 1: General

Requirements-IEC 60204-1. European Standard.

Frey G., Litz L., 2000. Formal methods in PLC

programming. IEEE Conference on Systems, Man and

Cybernetics, SMC 2000, Nashville, October 8-11.

IEC 60848, 1998. Specification language GRAFCET for

sequential function chart. ed. 2.

Klein S., 2005. Fault detection of discrete event systems

using an identification approach. PhD Thesis,

University of Kaiserslautern.

Machado, J., Seabra, E. A. R., 2008. Real-Time Systems

Safety Control considering Human-Machine Interface.

ICINCO’2008, May 10-14, Funchal, Madeira,

Portugal,. 6p.

Machado, J., Seabra, E. A. R., Campos, J., Soares, F. O.,

Leão, C. P., Silva, J. C. L., 2008. Simulation and

Formal Verification of Industrial Systems Controllers.

Symp. Series in Mech.; Vol. 3, pp.461-470.

Otter M., Årzén K., Dressler I., 2005. TaskGraph - A

Modelica Library for Hierarchical Task Machines.

Modelica 2005 Proceedings.

Seabra, E. A. R., Machado, J., Silva, J. C. L., Soares, F.

O., Leão, C. P., 2007. Simulation and Formal

Verification of Real Time Systems: A Case Study.

ICINCO’2007, Angers, France; May 9-12, 6p.

Ramadge P. J. and Wonham W. M., 1987. Supervisory

control of a class of discrete event processes. SIAM J.

Control Optimization, 25(1), pp. 206-230.

Rossi O., 2004. Validation formelle de programmes

Ladder Diagram pour Automates Programmables

industriels. PhD Thesis, École Normale Supérieure de

Cachan.

SAFE CONTROLLERS DESIGN FOR HIBRID PLANTS - The Emergency Stop

177