Distributed Product Development of a Fuel-Injection

System Using Multi-Agent

Zuhua Jiang

1

, Shiwei Fu

2

, Burkhard Lege

3

1

School of Mechanical Engineering, Shanghai Jiao Tong University,

Huashan Road 1954

Shanghai 200030, P. R. China

2

Kingdee international Software Group

Shenzhen 518057, P. R. China,

3

Konstanz University of Applied Sciences, Brauneggerstr 55

D-78462 Konstanz, Germany

Abstract. Multi-agent modeling has emerged as a promising discipline for

dealing with decision making processes in distributed information system

applications. One of these applications is the modeling of distributed design and

analysis processes which can link up various designs and simulation processes

to form a virtual consortium on a global basis. This paper proposes a

multi-agent cooperative framework for the development of a

fuel-injection-system including a fuel-injection-system and consisting of more

than 90 parts. The meta-model of management agent and actor agent for the

development of the fuel-injection-system is presented, and the architecture of

the distributed multi-agent system for the development of a

fuel-injection-system is discussed. The prototype system and some key agents

in the distributed product development are introduced.

1 Introduction

Design is increasingly becoming a collaborative task among designers or design

teams that are physically, geographically, and temporally distributed [1]. The

complexity of some products, e.g. the fuel-injection-system, makes it hard for a single

designer to complete the whole design task. The development of a

fuel-injection-system includes the product design, the structural analysis and the

performance simulation. Design is a team effort in which groups of designers with

different intent and background knowledge work together.

The characteristics of the development of a

fuel-injection-system are independent

team work and global control, as well as necessary negotiation between the teams.

Most tasks can be worked on in different teams respectively. But all results should be

controlled for the adherence to the given technological requirements and cost

Jiang Z., Fu S. and Lege B. (2006).

Distributed Product Development of a Fuel-Injection System Using Multi-Agent.

In Proceedings of the 2nd International Workshop on Artificial Neural Networks and Intelligent Information Processing, pages 45-53

Copyright

c

SciTePress

estimation during the long development period. In addition a lot of negotiation efforts

will be undertaken among the different teams to solve many kinds of conflicts.

Multi-agent systems are the product of a recent evolution in the field of software

engineering that is leading towards the development of decentralized, distributed

software systems composed of autonomous entities that interact and share information

with one another. A

NUMBA [2] presents a multi-agent system for collaborative design

in the construction sector. This system supports interaction and negotiation between

the different agents that represent various participants that are usually engaged in a

typical collaborative project design. Autonomy and co-operation are the important

behavioral attributes in multi-agent systems [3]. The approach is perfectly suited for

the development of a system for the distributed development of fuel-injection-systems

where expertise from different sources, and in different physical locations, is

encapsulated in separate modules that must then be integrated to address a user

inquiry. This paper is to investigate the feasibility of such an approach and to develop

a prototype system.

2 Meta-Model of Agent in the Distributed Fuel-injection-system

Development using Multi-agent

An agent is capable of (1) perceiving and acting at a certain level, (2) communicating

in some ways with other agents, (3) attempting to achieve particular goals or perform

particular tasks, and (4) maintaining an implicit or explicit model of its own state and

the state of its world [4]. Brustoloni’s taxonomy of software agents [5] begins with a

three-way classification into regulation agents, planning agents, or adaptive agents. A

regulation agent reacts to each sensory input as it comes in, and always knows what to

do. It neither plans nor learns. Planning agents plan either in the usual AI sense

(problem solving agent) or by using case-based reasoning or operations

research-based methods. The adaptive agents not only plan, but also learn. LIU [1]

present some agents in the architecture of a multi-agent design environment, which

includes design tool agent and communication agent.

Because designer is the active, and the computer and software are only the tools to

support design activities, some basic design tools and communication tools are used

as the fundamental support part of agent, not an independent agent in this paper. Two

classes of agents are defined and used in the system for the development of fuel

pumps: management agents and actor agents. Management agents are responsible for

the control and negotiation in the design process. The actor agents include among

others the design agent, the analysis agent, the simulation agent and. These agents are

situated on the different layers. The hierarchical relation limits the authority of the

agents in this environment. All kinds of computer tools will be used for the actor

agents and management agents to support communication and database management,

as well as system maintenance.

2.1 Meta-model of the Management Agent

Management agents are located on the server and manage the local or the whole

46

development group. The actions of the management agent usually include the decision

making process and the possibility to perform inquiries about as well as control and

supervise the lower layer agents. The task-oriented problem solving relation is a kind

of dynamic organized relation that is formed when agents complete the separate tasks

for a common design goal. The relation among agents is dynamically changed. As

soon as the tasks are fulfilled, the relation is dissolved voluntarily. All the

management agents in the fuel-injection-system development contain a design planer,

processor monitor, conflict negotiator and version controller. The meta-model of the

Management Agent is presented in Fig.1.

When a new task is defined, the new problem solving relation may be formed by a

group of new agents [6]. The design task will be split up and distributed to many actor

agents by the design planer according to the product development process and the

relation among the actor agents. This dynamic set of tasks and agents and their

relation among each other are watched and recorded by the process monitor.

Whenever a design event happens, the event monitor of process monitor will be

triggered.

Fig. 1. Meta-model of the Management Agent.

Co-operation between agents has been presented as one of the key concepts which

differentiates multi-agent systems (MASs) from other related disciplines and

application such as expert systems, distributed computing and distributed

object-oriented databases. Such a co-operation is essential for agents to achieve either

group related or individual objectives. However, co-operation between agents is often

challenged by a limitation of the resources. In such cases, negotiation is a major

approach to achieve the co-operation, in which agents attempt to reach a joint

decision between the teams of developers on matters of common concern which they

are in disagreement and conflict about. The conflicts between competitive

individualism and co-operative collectivism are resolved through negotiation [3]. The

activities during the design stages involve a lot of negotiation and exchange of

information between these design groups.

Several different negotiation mechanisms can be used in MAS, which mainly

include rule-based and case-based, as well as game theory and behavioral theory [7].

Here, the rules bases and case bases are used to be the guidance for human

interactions by the way of interaction between different agents. A solution must be

reached agreeable to all agents otherwise deadlock and failure occurs.

Collaborative design is a process that helps to find satisfying solutions. All the

design history records of design tasks performed in the past are managed by the

version controller. All the design information is stored in the data base of the

management agent. The knowledge in the knowledge base (KB) of a management

agent includes the entire design process knowledge map, as well as the rules bases

and case bases for negotiation in the local group. When an agent is added to or deleted

from the group, the corresponding knowledge of management agent will be modified.

47

2.2 Meta-model of the Actor Agent

The majority of agents in the fuel-injection-system development are design agents.

The analysis agent and the simulation agent also take part in the product development.

The design agents and analysis agents, as well as simulation agent, are included in the

actor agent, which is managed and controlled by the management agent. But every

actor agents is a kind of domain-dependent and semi-autonomous agent, it has its

design capacity and task. The meta-model of the actor agent is presented in Fig.2.

All the actor agents have a pre-processor, a core processor and a post-processor.

The core-processor in the actor agent has the following abilities:

z Doing routine works just like key part design and performance simulation, as

well as the dynamic analysis of an assembly and the structural analysis of key

parts by FEM.

z Maintaining and interpreting knowledge related to itself and other agents.

z Interacting with designers, catching the interest and habit of the designers and

recording this information in its knowledge base (such as recording the

completed cases).

An actor agent gets the information from its management agent with its sensors

and then translates it to the internal description of the situation. The pre-processor will

standardize the data from the management agent. Supported by the knowledge base

and model base, as well as data base, the core function processor will design, analyses

or simulate the given tasks. The post-processor will transfer the data from the core

function processor, and submit the report to its management agent.

Post-

Processor

Data Base Knowledge Base

Pre-

Processor

Core

Processor

model Base

Fig. 2. Meta-model of the Actor Agent.

3 Architecture of the Distributed Fuel-injection-system

Development Using Multi-agent

There are several research projects that focus on the application of agent and

multi-agent systems for collaborative design. The ACE project [8] undertaken at the

US Army Corps of Engineers construction Engineering Research Laboratories

(USACERL), investigated how to support collaboration among members of the

design team by providing an infrastructure for a community of cooperative design

agents that assist the users. The PACT project [9] demonstrates the applications of

agents in collaborative distributed design problems in which the project team

members are distributed over multiple sites, cut across various engineering disciplines,

and deploy different heterogeneous subsystems. There are several common ways of

structuring the agent community within MAS. The choice of structure will impose

48

relationships between agents that will fundamentally affect the way they communicate

and negotiate. A

NUMBA [2] concludes four ways of structuring the agent community,

which is

− organizational structuring

− contracting,

− multi-agent planning and

− peer to peer negotiation.

Here the organizational structuring way is used, because only in this architecture

there is one agent that has a global overview of the full task.

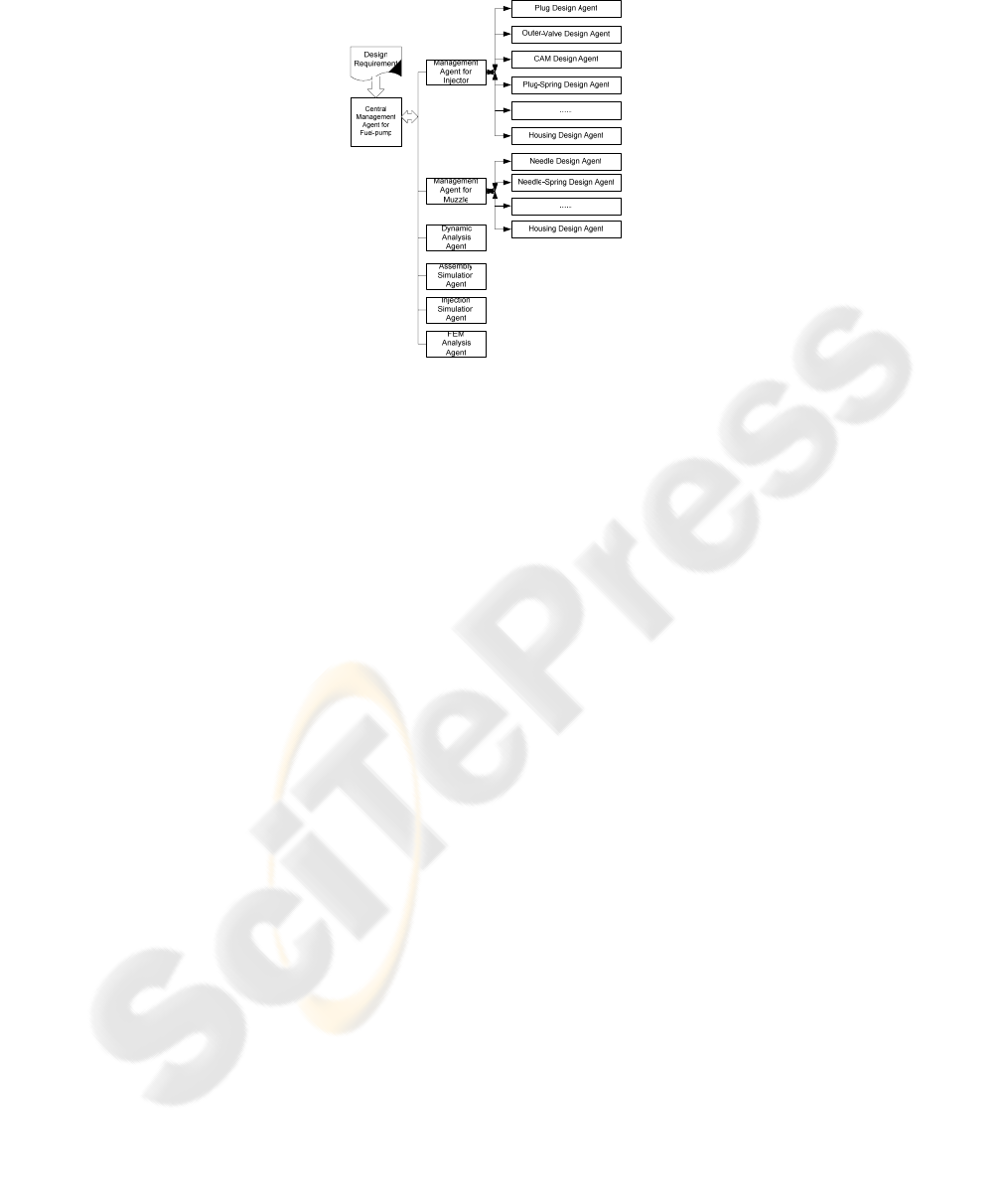

The central management agent controls the whole development process in the

system. After getting the design requirements, the central management agent will plan

the development process, and activate and link some agents in some domains. It will

also it monitor and negotiate the product development procedure in order to achieve

an appropriate cooperative development system. All the design conflicts from lower

lever agent will be solved according to the given technical and financial requirements,

until a satisfactory solution is achieved.

The actor agent is a kind of domain-dependency agent. It has some special

knowledge and abilities and can help designers in a special domain. The actor agent

files knowledge of the way how to design certain products based on the individual

strategies and preferences of the different human designers involved. It is constructed

to “understand” the representation of a design state, and contributes in a manner that

leads to successful solutions. The strategies used by the agent are based on

deterministic algorithms. In the current implementation, most agents are

semi-autonomous, but are triggered by the messages from the management agent. The

architecture of the fuel-injection-system development using a multi-agent system is

presented in Fig.3.

The product design contains the design and configuration of muzzle and injector.

The product design focuses on the key parameter calculation, and the product

configuration focuses on the detailed design using similar product cases from the case

base.

The assembly simulation is used to query the interference information for the

product structure. The dynamic analysis and the analysis by FEM are used to check

the maximum force to the key parts when the product is working, using special

simulation software.

Performance simulations contain the information about the injection performance

simulation and the matching simulation. The injection simulation is used to check the

injection process and some performance regulation, and matching simulation is used

to evaluate the match effects with diesel.

The management agent for the injector controls the design action of the plug

design agent, the outer-valve design agent, the CAM design agent, the plug-spring

design agent and housing design agent. It also solves the design conflicts among these

design agents. The management agent for muzzle has similar functions as the

injector’s agent.

49

Fig. 3. the architecture of distributed fuel-injection-system product development using

multi-agent.

4 Prototype System for the Development of a

Fuel-injection-system using Multi-Agent

Fuel-injection-system development process includes three stages, which are the

concept design stage, the configuration design stage, and the analysis stage. Some

tasks can be performed concurrently, if the working condition and relative parameters

of the actor agent is prepared well. The co-operation among different agents is

controlled by the management agent using message.

4.1 The Concept Design Stage

According to the technical requirement from the customer, the design task will be

split by the central management agent into several subtasks and be sent to the

collaborative agents. At the concept design stage, most design work will be done by

the design agents. But it is controlled by the management agent for the injector and

the management agent for the muzzle.

In the design process for the injector, the diameter of the plug is a key parameter.

After the diameter of the plug is confirmed, the design agent for the plug-spring and

the design agent for outer-valve can start to work. The design agent for CAM can

select the basic profile for motion. All these arithmetic tasks will be communicated to

the management agent for the injector.

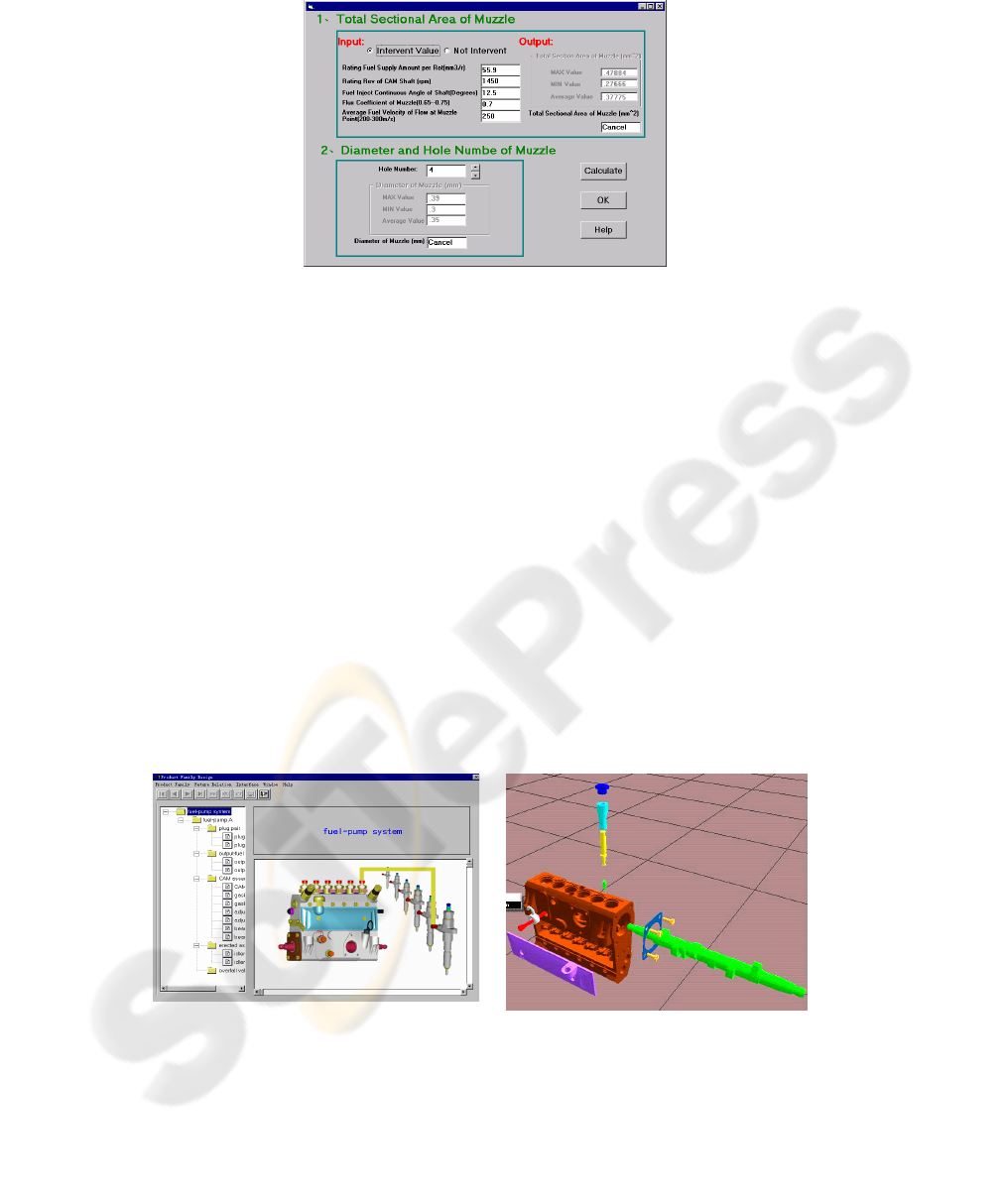

In the design process for the muzzle, the diameter and the number of holes for the

muzzle is confirmed firstly. Then the design agent for the needle spring can begin to

calculate its size and select its heat processing method, and the design agent for the

housing can calculate many parameters inside the muzzle house. Fig. 4 is one of

interface of the management agent for Muzzle.

50

Fig. 4. The Management Agent for the Muzzle.

4.2 The Configuration Design Stage

All the design agents take part in the configuration design stage. Each team member

with a different area of expertise will be primarily concerned with his own area of

interest. All design agents will take part in the new product development, and will

have to meet minimum design standards as defined with their internal knowledge

bases. The case-based design method is often used to support designing many parts.

But all the results will be verified by many standards and criteria. If the technical

performance can not be satisfied, the parameters of part will be re-designed using

some formula or rules. All the information of the successful part case will be saved in

the case base. Fig. 5 is an interface of design agent, also it display the BOM (Bill of

Material) and prototype of product.

After all the parts are modeled using CAD software, for example Pro/Engineering,

the assembly work can be done according to the structure style from the concept

design stage. The assembly simulation agent can check the space violation and some

conflicts in the assembly process (Fig. 6). When the assembly agent finds constraint

violation, it will inform collaborative agent to solve problem by coordination among

the design agents.

Fig. 5. The Configuration design for

fuel-injection-system.

Fig. 6. The simulation of assembly process.

51

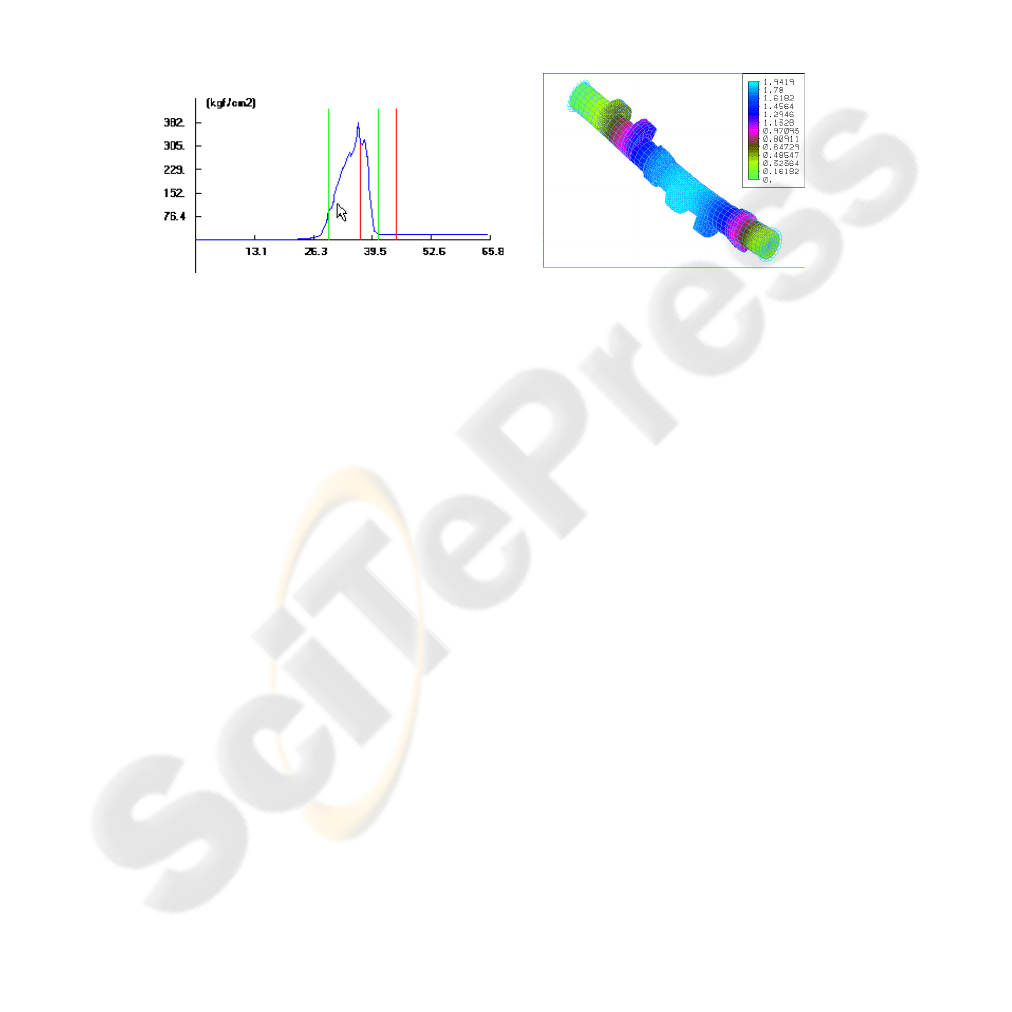

4.3 The Analysis Stage

In the analysis stage, the injection performance analysis is important, because the

injection process will affect the work process of the diesel combustion. The dynamic

analysis for the injector and the muzzle will be performed, and their results are used

for the FEM analysis of some key parts.

The injection simulation agent will calculate many kinds of injection

performances during the dynamic injection process, including the pressure of the fuel

at the point of the injector and at the outlet of the pump, as well as injection agile and

the displacement of the needle during an operating cycle (Fig.7). The whole injection

process can be simulated, and all the performances can be drawn using charts.

pump- end- pr essur e

rotating angle of camshaf t

Fig. 7. One of the simulation results of the fuel

injection.

Fig. 8. FEM analysis result of the cam

shaft.

If the injection performance is satisfied by the user, the modeling work for the

movement of injection can be done by the dynamic analysis agent. All the forces and

torques what the user want can be calculated, and its movement can be simulated.

Using the forces and torques from mechanical dynamic analysis, as well as some

constrains to structure, the stress of some key parts can be calculated by the FEM

analysis agent. Fig. 8 is to introduce one of the FEM analysis result of the cam shaft.

Each agent can also communicate directly with its management agent by the

internet. All the agents exchange design data and knowledge via a local network or

the internet via the management agent.

6 Conclusions

A key aspect of collaborative working between the multi-disciplinary teams involved

in the complicated product development is to facilitate the flow of information across

the heterogeneous software tools in use. This paper aims to investigate the use of

intelligent agents to facilitate collaborative design and focuses initially on the

development and design of a fuel-injection-system. This approach overcomes the

problem of geographically distributed teams.

Designers and design agents play the important role in the fuel-pump system

development. Actor agent is present to cover the function of regular part design and

assembly simulation, as well as dynamic analysis and performance simulation.

Management agent is used to control and negotiate the design process and parameter

52

transfer. All the computer and software are used to be the fundamental part of actor

agent and management agent, not the independent agent.

Organizational way of structuring the agent community is used to manage the

product development and to realize the design task. The actor agents are controlled

and triggered by the messages from the management agent. Some agents are

semi-autonomous, and some co-operation activities are limited. Pro-activeness is not

discussed in this paper, and actor agent can not exhibit goal-directed behavior by

taking the initiative.

Acknowledgements

The author is most grateful to National Nature Science Foundation of China (No.

2003CB317005) and Shuguang Program of Shanghai Educational Committee (No.

05SG15) for financial support that made this research possible. The author also thanks

the Konstanz University of Applied Science for the support of the cooperation

between the two universities in Shanghai and Konstanz.

References

1. Hong liu, Mingxi Tang, John Hamilton Frazer, Supporting dynamic management in a

multi-agent collaborative design system, Advances in engineering software, 35(2004),

493-502

2. C. J. Anumba, O. O. Ugwu, L. Newnham, A. Thorpe, A multi-agent system for distributed

collaborative design, Logistics Information Manage, 2001, 14(5/6), 355-366

3. C. J. Anumba, Z. Ren, A. Thorpe, O. O. Ugwu, L. Newnham, Negotiation within a

multi-agent system for the collaborative design of light industrial buildings, Advances in

engineering software, 34(2003), 389-401

4. K. S. Barber, J. Kim, Toward flexible tolerant intelligent manufacturing: sensible agents in

shop-floor control, artificial Intelligence in Engineering Design Analysis and

Manufacturing, 14(2000), 337-354

5. Brustoloni J C, Autonomous agents: characterization and requirements, Carnegie mellon

technical report CMU-CS-91-204, Pittsburgh: Carnegie Mellon University, 1991

6. Liu H., Lin Z. K., A collaborative design approach in MADS, Proceedings of the Fourth

International Conference on CSCW in Design 1999, 297-303.

7. Kraus S., Multi-agent negotiation under time constraints, Artificial Intelligence, 1995,

75(2),297-345

8. McGraw K. D., Lawrence P. W., Morton J. D., Heckel J., The agent collaboration

environment: an assistant for architects and engineers, Proceedings of the Third Congress

on Computing in Civil Engineering, Anaheim, California, June 17-19, 1996, 739-745.

9. Cutkosky M. R., Englemore R. S., Fikes R. E., Genesereth M. R., Gruber T. R., Mark W. S.,

Tenebaum J. M., Weber J. C., PACT: an experiment in integrating concurrent engineering

system. In: Huns M. N., Singh M. P., editors, Readings in Agents, San Mateo: Morgan

Kaufmann Publishers, 1998 56-65

53