A SAFETY SYSTEM FOR DYNAMIC VACUUM LIQUID

NITROGEN PIPELINE

For World Class Manufacturing Operation in Semiconductor Industry

Vinayak Divate

Spansion (thailand) Limited,Industrial Engineering , 229 Moo4 Changwattana Road Pakkred Nonthaburi Thailand 1120

Pichit Saengpongpaew

Spansion (thailand) Limited,Industrial Engineering , 229 Moo4 Changwattana Road Pakkred Nonthaburi Thailand 1120

Keywords: Liquid Nitrogen (Ln2).

Abstract: Liquid nitrogen is a colourless, odourless, extremely cold liquid and gas under pressure. It can cause rapid

suffocation when concentrations are sufficient to reduce oxygen levels below 19.5%. Contact with liquid or

cold vapors can cause severe frostbite. One volume of liquid nitrogen will expand to produce 696.5

equivalent volumes of gas. With this background Ln2 is being used in Semiconductor industry especially in

testing operation. The cold tests are taken on products at a temp up to -40C to -60C. The Ln2 is used in

testing machine to reduce test handler chamber temp. The chamber temp is required to maintain at -40 C

with allowance of + or – 3C to get accurate results. So this paper describes how Dynamic Vacuum ln2

pipeline system can be maintained smartly to get maximum benefits with minimum unscheduled shutdown

in semiconductor industry. This paper also gives the details about the safety system developed at

SPANSION Thailand limited for handling of ln2 through Dynamic vacuum ln2 pipeline system.

1 INTRODUCTION

In semiconductor industry Ln2 is handled in two

ways. 1) PLC (Portable liquid cylinders) is filled

from main cylinder and then PLC is moved from

filling station to tester machine. 2) Direct Ln2

pipeline system from main cylinder to Test chamber.

There are many advantages of direct pipeline system

over PLC, provided the ln2 requirement is more than

100KCum./month. Filling of PLC cylinders from

main tank involves loss of Ln2. The liquid turns into

gas. There are handling issues like weight of PLC,

quality of vacuum at PLC so on. So it is always

better to transfer Ln2 through piping system,

provided usage is more than 100KCum./month . Or

if the manufacturing requires to fill more than 15

PLCs /day with 200Kg /PLC. The Ln2 is handled in

various ways. The boiling point of ln2 is -195.8C.

So, it is very difficult to handle Ln2 in a liquid state.

In cold testing operation the handler chamber

required to get Ln2 in a liquid state. If ln2 is

provided in a gas state there is no heat absorption at

test chamber and it is considered as a loss of ln2. So

there are various methods of supplying of ln2. The

first and oldest type of supply system used simple

copper or stainless steel pipe wrapped with wood

insulation. Wood was later replaced by mica, then

shortly after polyurethane foam. Foam insulation is

highly inefficient and cumbersome, much of the

liquid nitrogen traveling through the pipe turns to

gas and pipe diameters with insulation are often over

8 inches. These large, bulky, inefficient piping

systems were relatively cheap to install, but the loss

of liquid nitrogen makes them to be very expensive

in the long run. Vacuums are one of the best ways to

eliminate heat conduction, so finally a dynamic

vacuum piping system was developed. This piping

system uses a pipe inside a pipe. To maintain a

thermo-arresting vacuum, the ultimate insulator,

between the two layers a vacuum pump is attached

to the line. The vacuum pump works continuously

twenty four hours seven days a week.

The dynamic vacuum piping system dramatically

decreased heat loss, and therefore was a much more

148

Divate V. and Saengpongpaew P. (2006).

A SAFETY SYSTEM FOR DYNAMIC VACUUM LIQUID NITROGEN PIPELINE - For World Class Manufacturing Operation in Semiconductor Industry.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 148-153

DOI: 10.5220/0001210401480153

Copyright

c

SciTePress

efficient system. While the dynamic system is much

more effective than foam, materials and installation

cost much more, and the time and maintenance

required for the pumping system is highly cost

ineffective due to electricity consumption.

Table 1: HAZOP table.

Guide

Word

Deviation Ln2

line

needs

to

stop?

Consequences Causes Suggest

ed

Action

More 120psi

Pressure

at PG1

No

need

Alarm will be

at 120 psi

VENTS

are off

no

handler

ON

Start

handler ,

check

VENT

There are four principal areas of hazard related to

the use of

Ln2. These are: flammability, high pressure gas,

materials, and personnel. All categories of hazard

are usually present in a system concurrently, and

must be considered when introducing a Ln2 system

or process The high pressure gas hazard is always

present when ln2 is used or stored. Since the

liquefied gases are usually stored at or near their

boiling point, there is always some gas present in the

container. The large expansion ratio from liquid to

gas provides a source for the build-up of high

pressures due to the evaporation of the liquid. The

rate of evaporation will vary, depending on the

characteristics of the fluid, container design,

insulating materials, and environmental conditions

of the atmosphere. Container capacity must include

an allowance for that portion which will be in the

gaseous state. These same factors must also be

considered in the design of transfer lines and piping

systems A very brief contact with ln2 at -195.8C

temperatures is capable of causing burns similar to

thermal burns from high temperature contacts.

Prolonged contact with these temperatures will

cause embitterment of the exposed members because

of the high water content of the human body. The

eyes are especially vulnerable to this type of

exposure, so that eye protection is necessary.

1.1 Designing Safety System for

Dynamic Vacuum Pipeline

The HAZOP study is done for Dynamic vacuum

pipeline system but it is done before installation of

pipeline. HAZOP: It is a hazard and operability

study. The Hazops procedure involves taking a full

description of a process and systematically

questioning every part of it to establish how

deviations from the design intent can arise. Once

identified, an assessment is made as to whether such

deviations and their consequences can have a

negative effect upon the safe and efficient operation

of the manufacturing plant. If considered necessary,

action is then taken to remedy the situation. This

study helps to design the safety system required for

Dynamic vacuum ln2 pipe line system. An essential

feature in this process of questioning and systematic

analysis is the use of keywords to focus the attention

of the team upon deviations and their possible

causes. These keywords are divided into two sub-

sets:

Primary Keywords which focus attention upon a

particular aspect of the design intent or an associated

process condition or parameter. Secondary

Keywords which, when combined with a primary

keyword, suggest possible deviations. The entire

technique of Hazops revolves around the effective

use of these keywords, so their meaning and use

must be clearly understood by the team. Examples of

often used keywords are listed below. Primary

words: Incase of Dynamic vacuum pipeline system

is Pressure, Vacuum, Temp, and Flow etc.

Secondary words: More, less, In the HAZOP study

we have to write a report on Purpose, Objective, and

Scope of study, Team members, and Data collection

by team members in following format. Showed in

Table 1.

But it has been observed that the users do not install

sufficient safety system while installation of

Dynamic vacuum pipeline system. For long term

success of Dynamic vacuum pipe line, it is very

clear that control over vacuum, and pressure are very

important. Usually, the manufacturers design

Dynamic vacuum pipeline system with many safety

release valves (SRV) to stop over pressurization.

Usually these valves are present at both sides of any

ln2 valve. Typically SRV operates at 120PSI,

170PSI as per requirement. But it is a one kind of

breakdown maintenance. It means, if the pressure

goes more than 120PSI the SRV fires. But one

important point is ignored and that it the firing of

SRV happens inside production floor. The ln2 gets

fired with smoky jet with loud cranking noise. It is

big disturbance to all operators around the line. It

also may decrease the percentage of O2 in

atmosphere. So, the operators need to go away from

work place causing production disturbance. Any

production disturbance can cost thousands of dollars.

So it is required to control the pressure with different

perspective. The Dynamic vacuum line should have

an additional safety system which should alarm on

over pressurization. The SRV is needed but that

should be the last choice. The control over vacuum

A SAFETY SYSTEM FOR DYNAMIC VACUUM LIQUID NITROGEN PIPELINE - For World Class Manufacturing

Operation in Semiconductor Industry

149

is also very important. Usually the manufactures

gives vacuum meters to monitor vacuum in the line.

But additional alarm system should be there to get

an alarm as soon as the vacuum is out of control.

Usually the vacuum slowly reduces if there is failure

of sealing. The gaskets or sealing fails over time

because of wear and tear. The user can make

necessary arrangement by controlling vacuum zone

valves. To describe a safety system let consider a

Dynamic vacuum pipe line system. The typical

picture is shown.

1.2 Designing of Dynamic Vacuum

Pipeline System

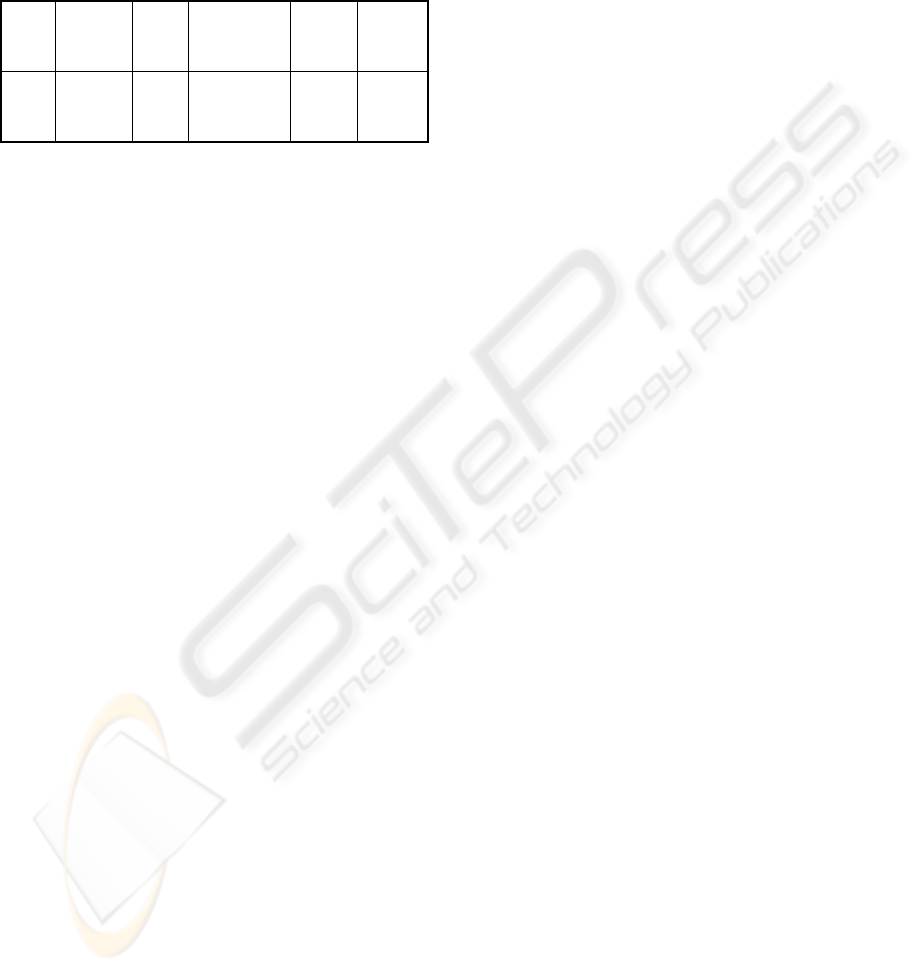

A typical Dynamic vacuum system fig1 is designed

to illustrate. The main tank is located at A, ideally

there should not be any pressure regulator on the

Dynamic vacuum pipeline; the pressure regulator

either expands or restricts the area of cross-section

and creates gas from liquid. Our main aim is to

provide 100% liquid nitrogen to test chamber. It can

not be 100% but we should tray to design a system

which can capable of supplying approximately

100% liquid. There is a main valve at A. The VENT

1 is installed to remove gas from liquid. The main

cylinder can not be a reservoir of 100% Ln2. So,

VENT1 is used to remove gas from liquid when

liquid flow from main tank to test chamber. Sub

main valves B and C are pneumatic actuated valves.

These vales can be opened and closed with N2 gas

supply ON and OFF. There are two more sub main

valves at F and D .These valves are installed to get

maximum flexibility. The flexibility of pipeline is

explained at the end of this article.

These are manual. VENT3 and VENT2 are

connected at the end of each line to achieve closed

loop pipe line. All generated gas in pipe line is

thrown away. PG1, PG2, PG3 are the pressure which

are installed just before end of line. They must be

installed just before end of line so that you can get

Figure 1: diagram of Dynamic Vacuum ln2 direct line.

ICINCO 2006 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

150

normalized pressure of that pipe section.VG1, VG2,

VG3 are installed at the end of pipeline so that we

can get a minimum vacuum achieved at the end of

line. It ensures that the recorded vacuum is certainly

present in that pipe section. The computerized

control

system is installed to control pneumatic valves at B

and C. It also monitors the signals from pressure

gauges and vacuum gauges.

2 SAFETY CONTROL SYSTEM

The safety control system has three parts A)

Monitoring and evaluation B) Audit review and

improvement and C) Emergency plan. To satisfy all

three requirements, two types of safety control

systems should be installed after installation of

Dynamic vacuum ln2 line. 1) Monitoring and

evaluation: It means the Dynamic vacuum system

should be real monitored for vacuum and pressure

parameters along the pipeline. The monitored results

should be compared or evaluated real time with set

limits. If there is any gap appropriate alarm system

should be ON real-time automatically. 2) Audit

review and improvement: For audits the old data is

required. So, the safety system should be capable of

producing the old data. There must be secured data

base and all vacuum and pressure parameters must

be stored real-time for future reference. Audits must

be done; Process capability index like Cpk must be

calculated automatically. C) Emergency plan: The

system should stop the supply of Ln2 from the main

tank in case of emergency. The emergency limits

must be evaluated and set with control system.

With this requirement the two kinds of safety

systems must be there along with Dynamic vacuum

pipeline system.

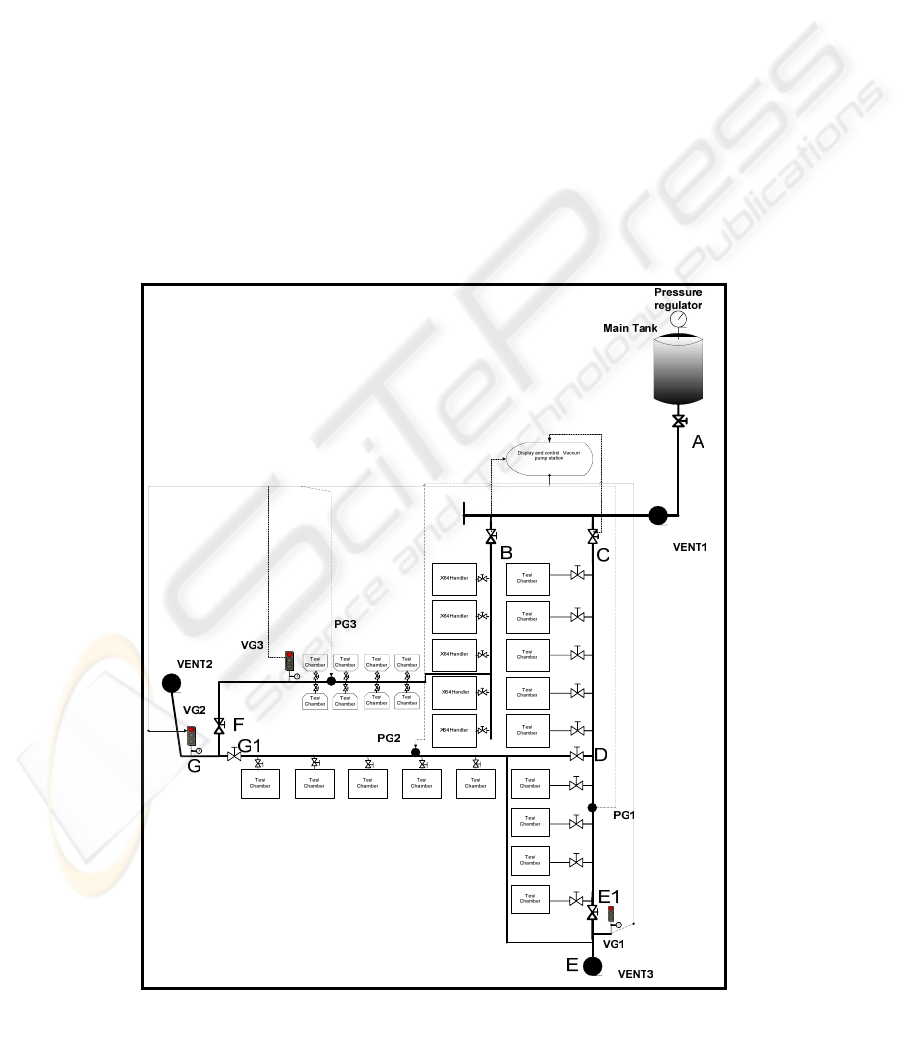

Analog control and alarm system. Shown in fig2;

As we know pressure and vacuum are the key

parameters; so, hardware should be selected in such

a way that it gives analog and digital signal. Usually

vacuum or pressure probe senses the pressure; it is

then collected by a meter which creates digital and

analog signal. Now let consider figure for the the

Dynamic vacuum pipeline system mentioned in fig3.

VG1, VG2, VG3 are the vacuum meters which send

analog and digital signal to control panel. The signal

transfer is explained in fig. We can set two limits in

vacuum meter lower and upper. So let us consider a

Dynamic vacuum pipeline whose vacuum is

controlled at 1mtor. The vacuum meter is set at

15mtor to give lower alarm and 30mtor to give

upper alarm. In normal working condition vacuum

meter should show reading 1mtor with some

allowance. But if there is any problem and vacuum

decreased to 15mtorr then vacuum meter sends

analog signal to control panel to activate lower

alarm. If the vacuum further decreased to 30m tor

the vacuum meter sends an upper alarm.

The control panel is equipped with relay circuit as

shown in fig 2. If it receives lower alarm then it will

make buzzer ON and a yellow light will start

blinking. If vacuum meter gets upper alarm it

actuates circuit to get Buzzer ON, red light starts

blinking it shuts off the solenoid valve which is

operated on gas .The valve shuts down. If you see

figure 5 and if VG1 senses the upper alarm then the

corresponding signal will go to controller; the

controller will actuate the signals to solenoid valves

at B and C. It will shut down the flow of Ln2 to all

Dynamic vacuum pipe line.

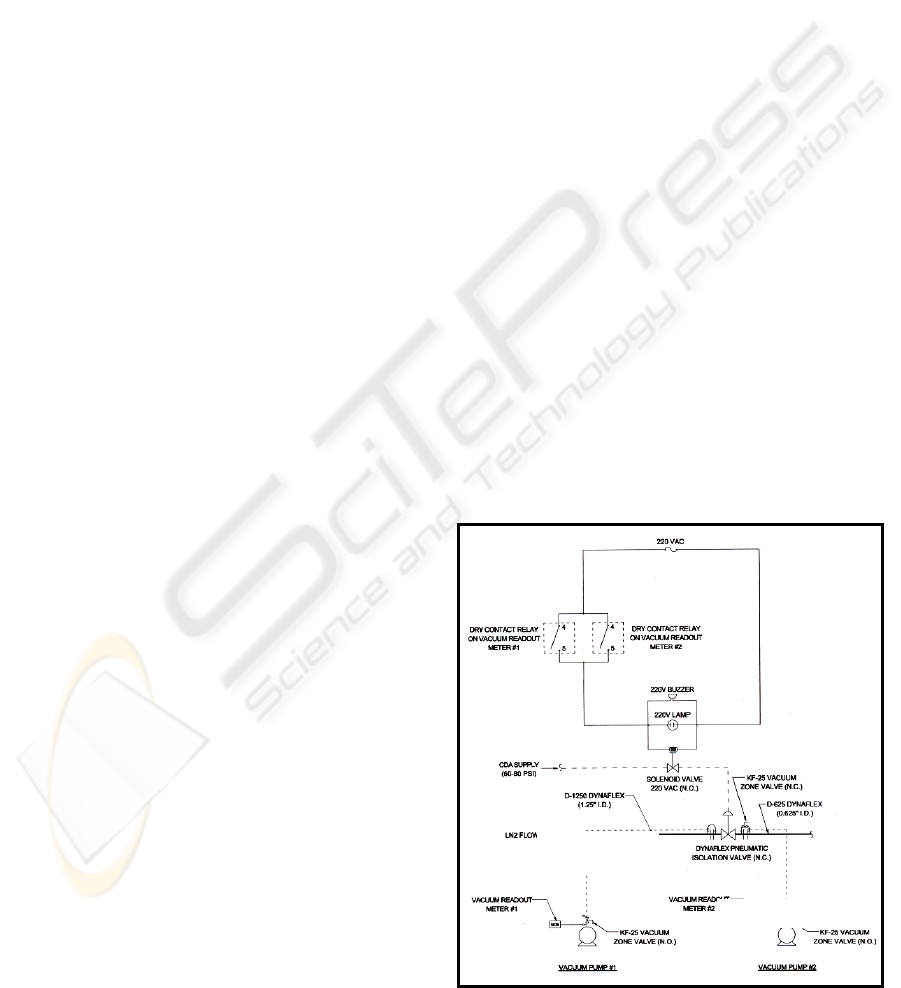

Digital Computerized Alarm and Control System.

Incase of digital control system see figure 3 & 4.

The vacuum and pressure meters give corresponding

digital signal. The signal comes by RS232. But

usually the computers are placed at controlling room

far from production floor. So we need to convert

signal from RS232 to RS422 to achieve better

accuracy. RS232 can be used when the computer is

not more than 50m away from vacuum or pressure

sensor. In above case RS422signal again converted

to RS232 at computer. The computer is installed

with multi COM cards. So a computer is capable of

receiving 15 signals from vacuum or pressure meters.

Figure 2: Analog control system.

Isolation Valve

Zone

Valve

Zone Valve

Zone

Valve

Pipe line

A SAFETY SYSTEM FOR DYNAMIC VACUUM LIQUID NITROGEN PIPELINE - For World Class Manufacturing

Operation in Semiconductor Industry

151

Now in above case customized software is designed

and developed which is capable of capturing the data

at COM ports. The data is stored in a secured data

base for future reference. So the software is capable

of sending and receiving data from sensors. The Cpk

is automatically calculated to get online process

capability index. The software is capable of plotting

real time data on statistical process control charts. It

is shown in the fig4

3 FLEXIBILITY OF DYNAMIC

VACUUM PIPE LINE

This is one more concept which must be taken into

consideration while designing of Dynamic vacuum

ln2 line. It is little costly to design a flexible line but

in long term it gives a lot of benefits. This concept is

especially useful when the manufacturing requires

zero down time. If the line is flexible, we can use the

line partially, avoiding total 100% shutdown.

COMPUTRIZED DIGITAL CONTROL SYSTEM

RS422 TO RS232

CONVERTOR

VG1

RS232

Computer with multiplw COM RS232 ports

Camera1

PG3VG2PG1

VG3VG2

Camera2 Camera3

RS232

RS422

Convertor

Sensor

Figure 3: Digital control safety system.

So, if the above Dynamic vacuum pipeline is

considered shown in fig 1. The pipeline is divided

into three parts Part A.

Figure 4: UI digital monitoring and data storage.

Table 2: Flexibility of Dynamic Vacuum line.

Sr .

No

Part of

Dynamic

vacuum

line

Number of

Outlets

Flexibility

1

Part 1-B

to F 13

13

If problem is in part1,

then close valve at B and

F;

Part 2 and 3 will get Ln2

from Valve C with

closed

2

Part 2 – C

to D to E

9

9

If problem is in Part 2 ,

Close the valves at C and

E1, D. The ln2 will come

to Part 1 and 3 from

valve

B to F to E giving closed

loop.

3

Part 3-D

to G 5

5

If the problem is in

Part3, Close the valve at

D, G1

still part 1 and 2 will

work as closed loop

pipeline.

4 RECOVERY ON BREAKDOWN

OF DYNAMIC VACCUUM LN2

PIPE LINE

In semiconductor industry the breakdown of any

utility system is a big crime. The testers are highly

expensive so, utilization of machines is very

important. Now if we consider break down of

Dynamic Vacuum system then it is more

troublesome as the Dynamic Vacuum ln2 line can

not be started unless the vacuum is back to normal

ICINCO 2006 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

152

level. So normally it takes 8 to 9 hrs for a section of

pipe of 100 feet by three vacuum pumps. In

SPANSION Thailand this problem is solved by

experimenting with Dynamic Vacuum line. In

SPANSION Thailand the vacuum pumps and

vacuum zone valves are arranged in such a way that

the 100 feet Dynamic Vacuum line can be

vacuumized by three pumps within 2 hrs. It is

achieved as follows.

a) N2 gas supply is arranged at four points

along Dynamic Vacuum line.

b) Three vacuum pumps at three equal

distances along 100 feet are suitable

installed. Vacuum zone valves are directed

in such a way that all pumps will pump

approximately 33 m of 100feet Dynamic

Vacuum line.

c) At starting, make all three pumps ON and

we have to purge N2 gas at liquid line and

vacuum line for 15 mins to remove

humidity.

d) Stop purging N2 gas at vacuum line and

pump vacuum for another 30 mins .

e) Stop N2 gas purging at liquid line and open

Ln2 to make all line cold enough to close

all micro holes along 100 feet Dynamic

Vacuum line for five mins at pressure 70psi.

f) The liquid is very cold and closes all micro

holes, the vacuum pumps gives very good

performance as there is no humidity.

g) Now pump for another 1 hr 10 mins ,

vacuum with partial ln2 in liquid line and

vacuum line with no humidity .

h) We can achieve vacuum at desired level of

50 to 60 mtorr in two to three hours. Now

we can open a liquid line fully to give ln2

to handlers.

Old method V/s New method

0

100000

200000

300000

400000

500000

600000

700000

800000

123456789

Time(hrs)

Vaccuum (mtorr)

old method : 100 feet pipe line for three pumps

New method :100 feet with three vaccuum pump.

Figure 5: Recovery on Breakdown.

5 CONCLUSION

We can say that Dynamic vacuum pipeline system is

the best choice if requirement of Ln2 is large at

manufacturing. Secondly the user must install or

invest sufficient money in customized development

of safety systems. The vacuum and pressure control

are the key elements .The two kinds of safety

systems must be installed, analog and digital. Both

systems give a lot of benefits in maintaining a

Dynamic vacuum ln2 line 24 hours 7 days week ON

without any accident. Analog system should be set at

two levels of alarm system. The first alarm is

precautionary alarm and the second alarm is for

system shut down. Digital system must be equipped

with good database design, customized user

interface, real time system for monitoring the signals.

The pressure at throughout Dynamic vacuum line

should be maintained as low as possible. It should be

controlled at main tank with tank mechanism. The

pressure regulators are loss making devices so,

should be avoided. The line should flexible enough

so that there will not be total shutdown of system. In

semiconductor industry recovery from system

breakdown should be in minimum time so proper

contingency plan and Dynamic Vacuum system

must be installed accordingly.

REFERENCES

http://www.vbsflex.com/dynamic vacuum .html

http://www.isograph-software.com/hazover.htm

Spansion Thailand EHS specs

Objectifying Real-Time Systems/Book and Disk by John

Ellis

Real-Time Systems Design and Analysis by Phillip A.

Laplante

A SAFETY SYSTEM FOR DYNAMIC VACUUM LIQUID NITROGEN PIPELINE - For World Class Manufacturing

Operation in Semiconductor Industry

153