NEURAL NETWORK SYSTEM FOR WASTE-WATER

RECOGNITION

Radek Kuchta, Radimir Vrba

Department of Microelectronics, Brno University of Technology, Udolni 53, 602 00 Brno, Czech Republic

Keywords: Neural network, waste-water, DSP, PCA.

Abstract: This paper presents modern method of using neural network for waste-water recognition by using sensor

array. Each sensor in sensor array detects chemicals in waste-water with different sensitivity. Set of

measured data is digitized and recognized by a neural network. Measuring process doesn’t need any human

operator. The result gives the only information: contaminated or not contaminated.

1 INTRODUCTION

Many Internet service providers and online services

require you to manually enter information, such as

your user name and password, to establish a

connection. With Scripting support for Dial-Up

Networking, you can write a script to automate this

process.

Many manufacturing companies and manufacturing

plants produce a lot of impure waste-water. This

water is processed thru sewerage plant and after

cleaning it is delivered to the wide open space. It is

necessary to test quality regularly for quality

assurance. It is possible to use different methods of a

chemical analysis for these tests. The price and

necessity of human operators are the main

disadvantages.

The main motivation for sensor array based devices

developed is to design low cost, precise, mobile

devices for reproducibility of analyzing of impure

waste-water in real-time mode. These devices are

produced for classification and recognition of

liquids, gasses, foods and other substances.

2 SENSOR ARRAY APPLICATION

In many applications for chemical sensors,

information can be gathered not only from a steady-

state value of a sensor response, but also from the

kinetics of response. However, using steady-state

sensor value to classify different mixture liquid

chemicals results in losing of a great deal of

information in the sensor signal.

The main function of these devices is to identify and

quantify structure of chemicals. The system consists

of the array of electrochemical sensors. This array

contains sensors of various types. Each sensor

detects more than one chemical, some of them with

higher sensitivity, and some others with lower

sensitivity, depending on individual sensor

characteristics. Sensors are fixed in a temperature

stabilized vessel filled with measured liquid mixture.

Sensor response is digitized by an AD converter.

There are another temperature and humidity sensors

located in gas chamber, too. The set o digitized data

is forwarded to the bus-connected computer for final

recognition and analysis.

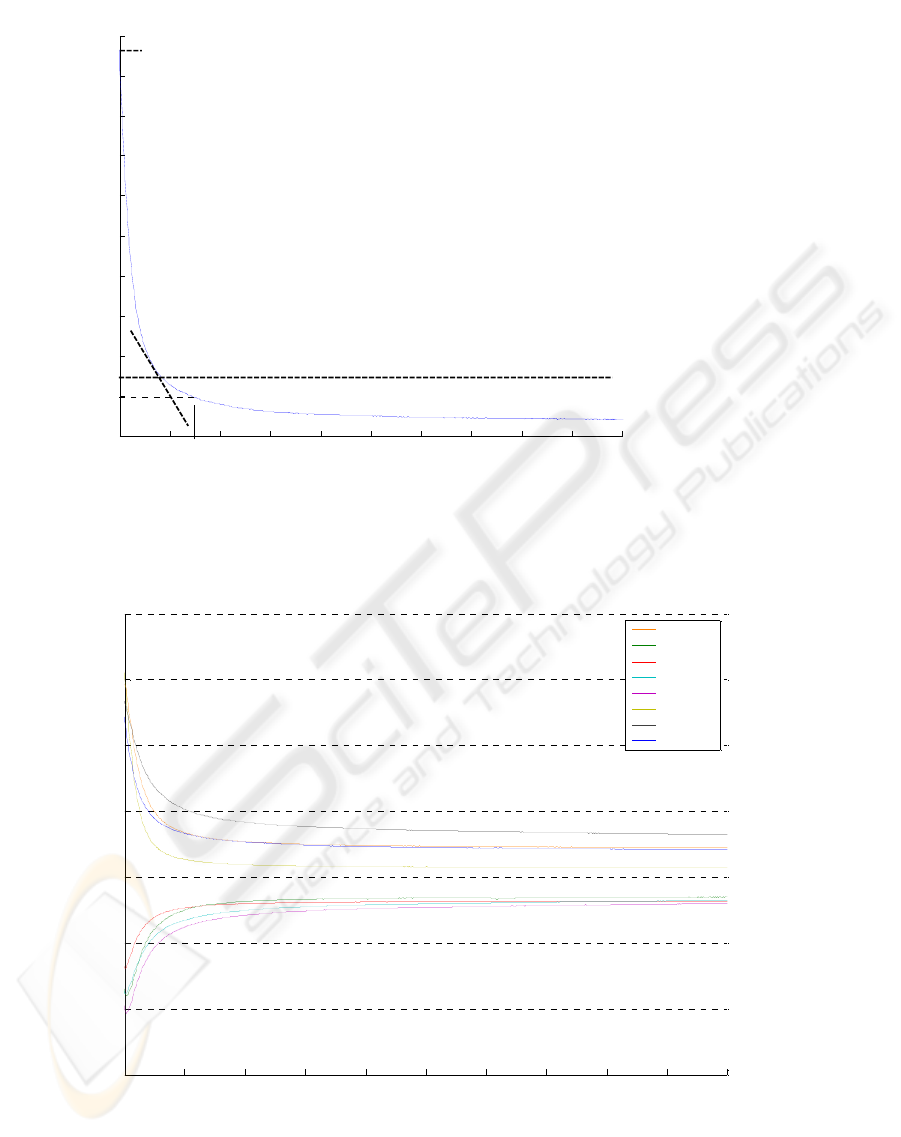

To recognize all chemicals of waste-water, it is

necessary to make analyses of all measured data. It

is possible to exploit several methods to reach

analyzed results. One of these methods is to extract

the main measured curve parameters by hand. Four

fundamental curve parameters (Vernat-Rossi, et al.,

1996) are depicted in Figure. 1: kmax for maximum

slope, max for maximum value, sr30 for the

response on time 30 s and mean for average value of

the whole set of points. This method is not much

competent, because the target is to design an

autonomous system, which works without operator’s

assistance.

199

Kuchta R. and Vrba R. (2006).

NEURAL NETWORK SYSTEM FOR WASTE-WATER RECOGNITION.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 199-202

DOI: 10.5220/0001208201990202

Copyright

c

SciTePress

Figure 1: Sensor response curve with fundamental analyzing parameters.

Figure 2: Sensor array response curve.

0 20 40 60 80 100 120 140 160 180 200

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

time [s]

sensor response [V]

sensor1

sensor2

sensor3

sensor4

sensor5

sensor6

sensor7

sensor8

0 20 40 60 80 100 120 140 160 180 200

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

time [s]

sensor response [V]

max

mean

kmax

t = 30 s

sr30

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

200

S

1

S

2

S

3

S

n

H

1

H

2

H

3

H

n

O

sensor array output layerhidden layer

sensor 1

sensor 2

sensor 3

sensor n

input layer

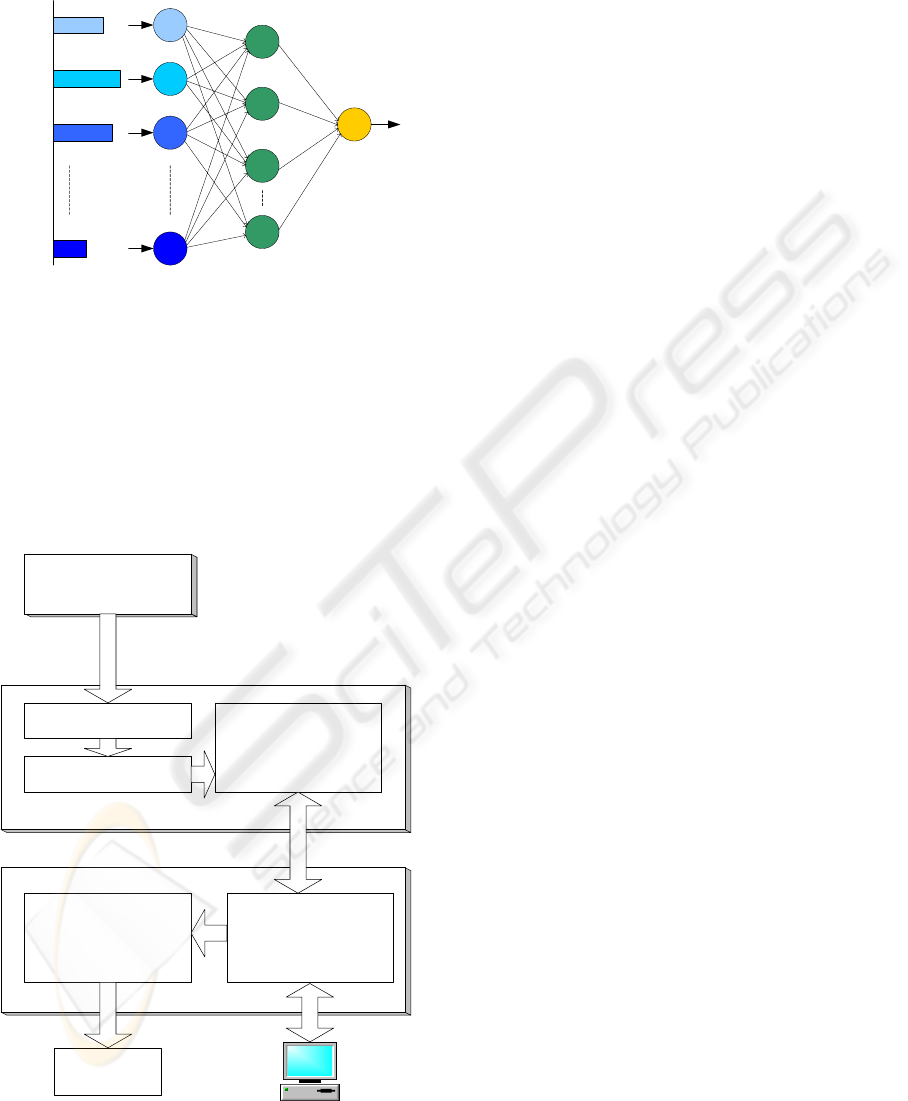

Figure 3: Block diagram of neural network processing

signals stimulated by n sensors.

Another method selects main typical points, then

tries to approximate measured values and finally

compares them with those derived from the

mathematical model. If too many features are used,

mathematical model will be huge and complex. For

this reason it is necessary to reduce number of points

which are used for recognition without losing

resolution.

processor part

sensor array

multiplexer

ADC

preprocessor unit

I/O portsneural network

LCD

display

PC

A

B

Figure 4: Block diagram of recognizing system.

If the sensor array contains eight different sensors

with various characteristics, their responses to

analyzed liquid mixture generate eight different

characteristics. The reason is that each sensor works

with different sensitivity to different chemical

components. Sensor array response curves are drawn

in Fig. 2. For description of these characteristics it is

possible to use e.g. four parameters, which describe

measured data with sufficient resolution. We know

the wage of measurement exactly in time which is

near stable-state. Therefore, from each curve, 4

fundamental parameters are extracted (Fig.1), and

for 8 sensors we collect totally 32 values.

These 32 parameters may form input values for

appropriate statistical method for data processing

and analysis.

3 NEURAL NETWORK

An artificial back-propagation neural network is

very often used for detailed recognition. There is a

block diagram of the neural network shown in Fig.

3. The input layer has the same number of neurons

like the number of input values. Number of neurons

in the output layer depends on the desired values. In

this application we usually want to know, if waste-

water is contaminated or not. It means that number

of the output neurons will by only one. The artificial

neural network will be realized by a microprocessor

or a DSP digital signal processor.

Block diagram of the system is shown in Fig. 4. The

system co-operates with external or internal sensor

array. Sensors´ responses are converted and digitized

in part A of the recognition system. Superimposed

signal noise is suppressed by a noise filter in part A,

too.

Recognition part and the neural network are situated

in part B of the system. The system is connected to a

personal computer via a standard (RS-232 or USB)

interface for measured data storing. Essential

information resulting the sensor signal processing is

displayed on embedded LCD display. In much more

details the results are available in a connected PC

frame.

4 CONCLUSION

For waste-water recognition several methods may be

exploiting. This paper presents the basic description

of a low cost method, which works in real-time

mode without device operator assistance. This

NEURAL NETWORK SYSTEM FOR WASTE-WATER RECOGNITION

201

method can be used to recognize liquid components

in a sewerage plant. It is based on sensor array, used

to measure concentration and composition of

chemicals. Neural network is used for final

recognition. The final result of recognition gives the

binary information: contaminated or not

contaminated, which is sufficient.

ACKNOWLEDGEMENTS

The research has been supported by the Czech

Ministry of Education in the frame of MSM

0021630503 MIKROSYN New Trends in

Microelectronic Systems and Nanotechnologies

Research Project, partly supported by Micro- and

nano-sensor structures and systems with embedded

intelligence (MINASES), GACR 102/06/1624

Project financed by the Czech Science Foundation

and under the contract GA102/03/H105

REFERENCES

Šnorek, M., Jiřina, M.: Neuronové sítě a neuropočítače.

Praha, Vydavatelství ČVUT 1996, ISBN 80-01-

01455-X

Bíla, J.: Umělá inteligence a neuronové sítě v aplikacích.

Praha, Vydavatelství ČVUT 1996, ISBN 80-01-

01275-1.

Sinčák, P., Andrejková, G.: Neurónové siete Inžiniersky

prístup (1. diel). Košice, ELFA Press 1996, (in

Slovak)

Sinčák, P., Andrejková, G.: Neurónové siete Inžiniersky

prístup (2. diel. Košice, ELFA Press 1996, (in Slovak)

Neruda, R.: Umělé neuronové sítě a jejich použití

v lékařských datech.

Xiaobo, Z., Jiewen, Z., Shouyi, W., Xingyi, H.: Vinegar

Classification Based on Feature Extraction and

Selection From Tin Oxide Gas Sensor Array Data.

International symposium on sensor science – I3S

2003, Paris (France), ISSN 1424-8220

Gardner, J.W.; Bartelet, P.N.: Electronic nose: Principles

and Applications. Oxford University Press 1999, 1-4,

pp. 185-207

Christophe, S. et al.: Potential of semiconductor sensor

arrays for the origin Authentication of pure valencia

orange Juices. Journal of Agricultural & Food

Chemistry 2001, 49, pp. 3151-3160,

Giuseppe, Z. et al.: Determination of organic acids, sugars,

diacetyl, and action in cheese by high performance

liquid chromatographic. Journal of Agricultural &

Food Chemistry 2001, 49, ISSN 2722-2726, Sensors

2003, 3 109

Vernat-Rossi, V., Garcia, C., Talon, R. et al.: Rapid

discrimination of meat products and bacterial strains

using semi-conductor gas sensors. Sensors and

Actuators B 1996, 37, pp. 43-48.

Vrba, R. et al.: ANTOPE Research of New Methods for

Instrumental Analysis of Toxicity for Integral

Measurement of Toxicity in Food Industry and Their

Confirmation by a Prototype of Analyzer of the

Toxicity of Pesticides. MPO FD 42K/253 R&D

Project, Research Report, FEEC BUT and MPO, 2002

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

202