INTEGRATING WORKFLOW EXTENSIONS INTO A

PROCESS-INTEGRATED ENVIRONMENT FOR CHEMICAL

ENGINEERING

Michalis Miatidis

1

and Matthias Jarke

1,2

1

Informatik V, RWTH Aachen, 52056 Aachen, Germany

2

Fraunhofer FIT, Schloss Birlinghoven, 53754 Sankt Augustin, Germany

Keywords:

Design Processes, Chemical Engineering, Workflow Management, Method Guidance, Process Integration.

Abstract:

Design is one of the most complex and creative tasks undertaken by chemical engineers. The early production

stages of chemical design require an adequate support because of their critical impact on the competitiveness

of the final products, as well as their environmental impact. In cooperation with researchers and industries

from the chemical engineering domain, we have created an integrated flowsheet-centered environment for the

support of the early stages of design. In order to address the global need for enterprise integration observed

in today’s highly competitive global economy, we had to make our system more aware of further organiza-

tional aspects of the executed processes. As a solution to this challenge, we integrated a number of workflow

extensions into our environment. These extensions enabled it to provide its method guidance further across

the inter- and intra-enterprise environment of our enacted processes, with the future goal of seamless inter-

operating with other external systems of the overall enterprise environment. In this paper, after capturing the

rationale behind the need for this integration, we successively describe the integrated environment and detail

the extensions employed. Finally, we illustrate our approach on a small case study from our experience.

1 INTRODUCTION

The support of chemical engineering design processes

is a very challenging task because of their creative na-

ture and critical role in the overall production. They

primarily include the original specification, simula-

tion and evaluation of several design alternatives of

a chemical product participating in a production life-

cycle. It can be argued that these early stages have a

great impact on most of the sensitive characteristics

of the whole production like the final product quality,

the cost of the overall investments and operations, as

well as the duration.

We address the demand for supporting the early

stages of design processes in chemical engineering in

the SFB 476 IMPROVE research project (Nagl and

Westfechtel, 1998). In this project, in cooperation

with chemical and plastics engineering experts, we

investigate the early phases of the polyamide6 pro-

duction, the so-called conceptual design and the ba-

sic engineering. To this end, we have developed

a process-integrated design environment that is able

to directly provide the engineers performing the de-

sign processes with situated fine-grained process sup-

port based on previous recorded experiences (Jarke

et al., 1999a). This environment is built on top of

PRIME (Process Integrated Modelling Environment)

(Pohl et al., 1999). PRIME process support is given

in the form of method guidance based on the inter-

pretation of method definitions of some well-known

parts of the processes. Through a process integration

mechanism, the behaviour of the participating tools is

automatically adjusted according to the method defi-

nitions that apply to the current situation.

The contemporary business trends are clearly to-

wards the need for a global integration, either within

a company (intra-integration) or among several enter-

prises (inter-integration) (Vernadat, 1996). In order to

keep our environment up to date with these changes

in the manufacturing world, we needed to reflect the

organizational nature of the enacted design processes

in our environment by further addressing the inter-

networking issue of the engineers provided with sup-

port throughout supply chains. In pursuit of this goal,

we have extended our initial approach with workflow

extensions that reflect the more coarse-grained enter-

prise nature of process execution.

In section 2 we detail the motivation for this inte-

gration by successively comparing the workflow man-

agement support with the method guidance and de-

scribing the integrated modelling approach that has

driven us. In section 3 we introduce our process-

integrated design environment built upon PRIME and

detail the extended metamodel adapted in pursuit of

the integration goal, and in section 4 we illustrate

our results on a small case study from the IMPROVE

255

Miatidis M. and Jarke M. (2005).

INTEGRATING WORKFLOW EXTENSIONS INTO A PROCESS-INTEGRATED ENVIRONMENT FOR CHEMICAL ENGINEERING.

In Proceedings of the Seventh Inter national Conference on Enterprise Information Systems, pages 255-260

DOI: 10.5220/0002522602550260

Copyright

c

SciTePress

project. Finally, in section 5 we provide some conclu-

sions and outlook to future work.

2 MOTIVATION

2.1 Workflow Management versus

Method Guidance

Both method guidance and workflow management

contribute to the support of processes being executed

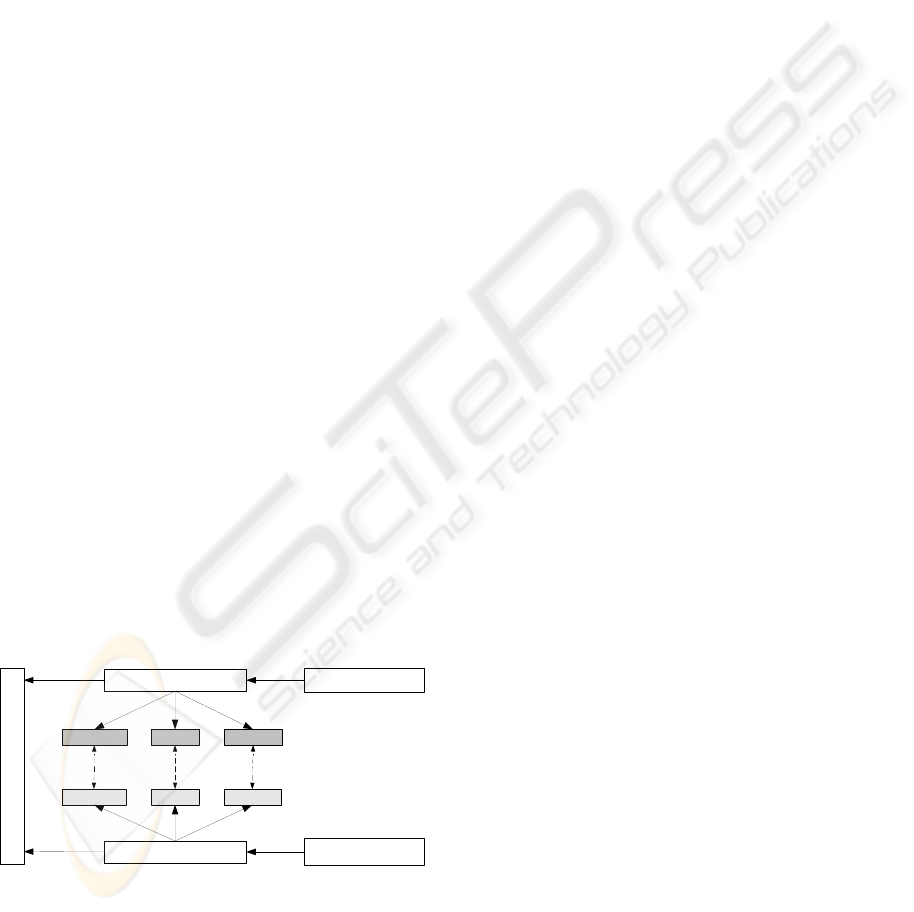

(figure 1). Nevertheless, each one of them supports

the executed processes at a different level of granu-

larity and from a different perspective. They differ in

three main aspects:

• The primary concern of workflow management

is the process-centric automated coordination of

the interworking of human actors at the execution

level. In contrast, method guidance aims at directly

supporting the human actors performing these ac-

tivities by defining their detailed methods of work-

ing.

• The products considered by workflow management

and method guidance vary in their granularity. The

process logic of a workflow model considers the

products at the level of documents. Method guid-

ance, on the other hand, cares of the product struc-

ture of these documents as they are considered in a

more fine-grained level by the method definitions.

• Workflow activities are bound to a number of re-

sources that perform some work on behalf of them

at runtime. These resources mainly contain the par-

ticipating human actors, tools and computer sys-

tems. Since method guidance is restricted to some

activity performed by a human actor at an engineer-

ing workplace, the main resources it considers are

the involved tools.

Workflow Management

Method Guidance

Workflow Management

System

Method Guidance

Environment

provides

provides

Process Execution

supports

supports

Products

ProductsActivities Resources

Methods Tools

Figure 1: Two levels of support to process execution.

The need to provide process support and automa-

tion to the execution of business processes, has lead

to the appearance of a variety of workflow manage-

ment and method guidance standards utilized by large

enterprise information systems. The area of work-

flow management stems from the traditional area of

office automation solutions. These solutions were ori-

ented to the automation of office processes performed

by human actors. Most of the modern approaches

have been widely applied in banks, insurance com-

panies etc to manage organisational issues of routine

processes most of the times with no or little human

intervention (van der Aalst and van Hee, 2002).

In the area of method guidance we can identify the

traditional handbooks that have dominated the indus-

trial practice, to the more modern separate guidance

tools displaying to the user a list of valid method de-

finitions that apply to his given situation, e.g. (Nu-

seibeh and Finkelstein, 1992).

None of the above solutions is able to provide a

fully integrated method guidance being at the same

time aware of the enterprise coordination issues, with-

out underestimating the non-determinism of the in-

volved processes. Workflow management systems

provide technical support for the automated coor-

dination of processes that are supposed to be pre-

cisely known in advance. Most of the researchers

of this field focus on the workflow management sup-

port and the possible ways of integrating it with the

higher level of project management or enterprise re-

source planning (ERP) e.g. (Cardoso et al., 2002),

(zur Muehlen and Rosemann, 2004) but neglect the

method guidance to the human actors performing the

processes. On the other hand, the existing method

guidance techniques are concerned with short-lived

methodologies that deal with individual activities or

participants and neglect other more managerial and

organisational activities. A gap clearly exists between

the two levels of support that has not been adequately

investigated in the literature and needs to be bridged.

2.2 Integrated Modelling Approach

Workflow management supports the executed

processes based on the explicit definition of a work-

flow model capturing the process logic. On the other

hand, method guidance is specified in process models

capturing the method definitions (methodology) for

performing a task. Thus, method definitions provide

a zoomed view of workflow activities and detail the

ways of working of the human actors performing

them. Also, the products and resources are seen

as black boxes on the task level and are zoomed to

their structure on the method guidance level. The

resources are actually considered only on their tools

by the method definitions. As a consequence, we

can defined three ‘semantic bridges’ among the

interrelated elements of the two levels:

1. A mapping relationship between a workflow activ-

ity and the methods providing guidance to the en-

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

256

gineers during that activity execution.

2. An isA relationship from the products (documents)

of the workflow model to their detailed view on the

method guidance level.

3. An isA relationship from the tools belonging to the

resources of the workflow model to their detailed

descriptions on the method guidance level.

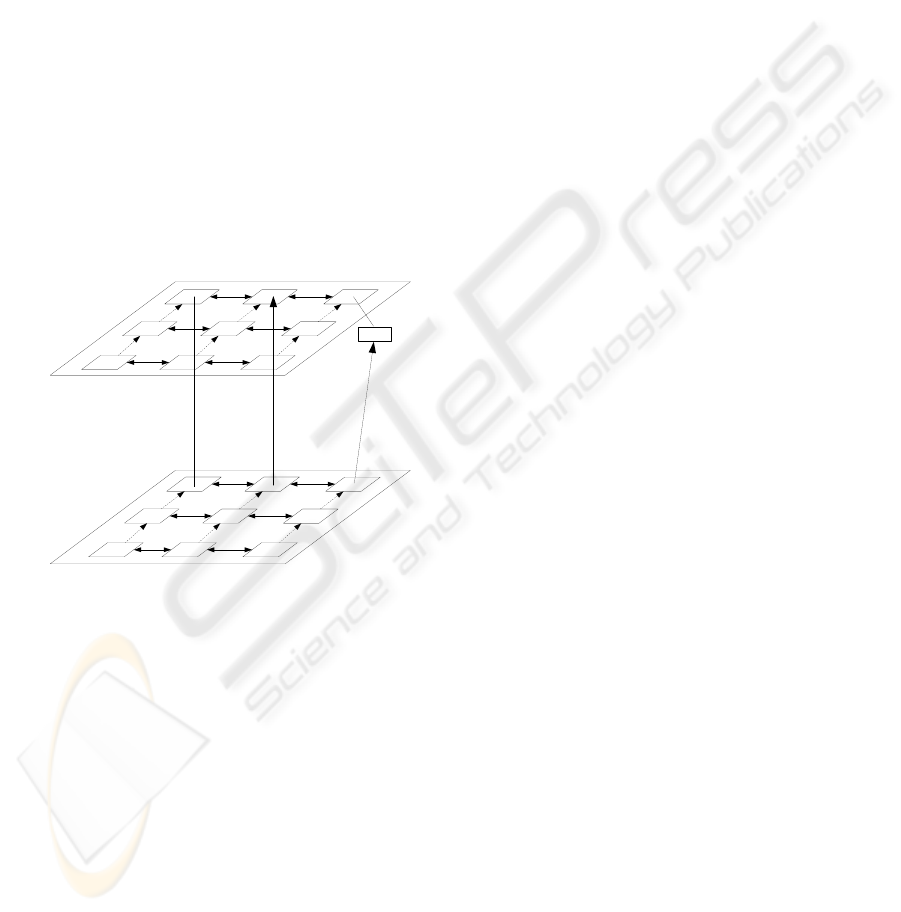

We have defined an integrated modelling approach

that is based on these semantic bridges and integrates

the interrelated concepts of the two levels of support.

In figure 2, a 3-dimensional view of this approach

is presented. The upper part represents the workflow

management level and the lower part the method guid-

ance level. On each one of them, we can identify the

contributed concepts. On the upper, we have the ac-

tivities, the products manipulated by them and the in-

volved resources. On the method guidance level, we

identify the engineering methods, the products they

change and the involved tools.

Workflow Management

Level

Method Guidance

Level

Metamodel

Model

Application

Activity

Product

Resource

Method Product

Tool

Metamodel

Model

Application

mapping isa isa

Tool

Figure 2: Integrated modelling approach.

In order to provide a generic modelling formalism

that is powerful enough to capture a wide range of

design scenarios and not restrict to just some specific

cases, we have followed the IRDS standard (ISO/IEC,

1990) and have created a three-layered hierarchy for

each level as shown in figure 2. The metamodel layer

plays the role of a generic kernel which is domain-

independent. Due to the generality of its underly-

ing concepts, it can be applied in different creative

domains of design. The model layer provides the

domain-specific knowledge of specific design scenar-

ios by instantiating the metamodel level entities. In

other words, the model layer provides a description

of the ideal world. The real world is captured on

the application layer. This layer instantiates concepts

of the model layer and captures traces of the actual

process execution. The two modelled levels are inte-

grated defining static relationships on the metamodel

level for each semantic bridge among the relevant el-

ements.

In the next section, we present the PRIME-based

design environment that has been extended accord-

ing to our integrated approach. Since PRIME was

already providing the fine-grained method guidance

support, we followed a bottom-up approach and ex-

tended its metamodel with elements from the coarse-

grained workflow management level according to the

three aforementioned semantic bridges.

3 PROCESS-INTEGRATED

DESIGN ENVIRONMENT

3.1 The PRIME-based

Flowsheet-centered Architecture

PRIME is able to provide integrated method guidance

to engineers based on the reuse of traced experiences.

The core component of PRIME is a process engine

that provides process support (automation, guidance

or enforcement) based on the interpretation of method

fragments and product object schemata, maintained in

a Process Data Warehouse (PDW) (Jarke et al., 2000).

The method guidance is provided to the user

through a process-integration mechanism (Pohl et al.,

1999) of the engineering tools. Process-integrated

tools are able to adapt their behaviour according to

the current enactment state and actual method defini-

tions (process sensitivity), provide support to the en-

gineers for direct invocation of method fragments and

return feedback information on service execution.

The capabilities of the process-integrated tools are

explicitly defined in tool models and are integrated

with process models providing the method guidance

definitions. Processes are modelled using a situation-

based contextual metamodel, initially proposed in the

NATURE project for the requirements engineering

process (Jarke et al., 1999b). A user is at any time

in a subjectively perceived situation made of a set of

states of the products undergoing the development. In

every situation, he has a given intention in his mind

and the conceptual bridge between a situation and the

valid intentions is called context. Contexts can be fur-

ther refined to executable, choice and plan contexts.

Executable contexts automate pieces of a process and

are usually realized by tool functions,choice contexts

describe the need of the engineer to make a decision

among several alternatives and plan contexts define a

systematic plan of steps that the engineer has to fol-

low. Tools are modelled with respect to their capabil-

ities (actions exposed and graphical user interface el-

ements) with a tool metamodel. The two metamodels

are integrated into the environment metamodel (lower

INTEGRATING WORKFLOW EXTENSIONS INTO A PROCESS-INTEGRATED ENVIRONMENT FOR CHEMICAL

ENGINEERING

257

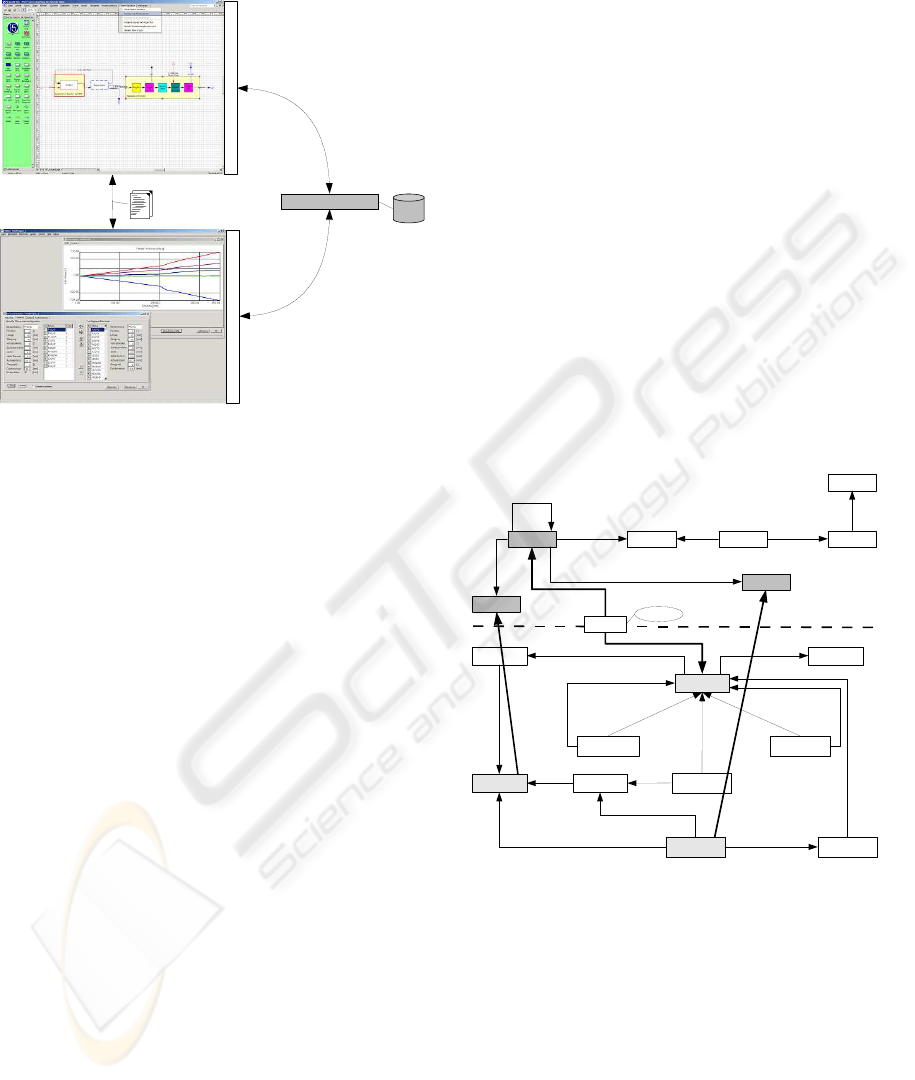

part of figure 4).

Process Engine

Flowsheet Editor

Flowsheet Editor

Process Integration Wrapper

PDW

Process Integration Wrapper

MOREX

Figure 3: Integration architecture.

We have built our integrated design environment on

top of a flowsheet-centered PRIME architecture. We

have realized a novel flowsheet editor (Bayer et al.,

2001) on the basis of the Microsoft Visio commer-

cial drawing tool. Through the process integration

mechanism, we have defined method fragments mod-

elling the basic interaction patterns of the engineers

while working on flowsheets. Some of the features

we stressed were the ability of displaying different re-

finement alternatives to the user and the simultane-

ous display of different refinement abstraction levels

in the same flowsheet view.

In order to make the data of the flowsheet acces-

sible from outside, integration with other domain-

specific tools was demanded. This exchange of infor-

mation among heterogeneous tools, is supported by

special integration tools (Becker et al., 2002) that, un-

der the supervision of the process engine, ensure data

consistency between documents. Figure 3 shows a

part of the actual integration architecture which inte-

grates the central flowsheet editor with the MOREX

(Schl

¨

uter and Haberstroh, 2002) compounding ex-

truder simulation tool. Contrary to our flowsheet ed-

itor, MOREX was loosely process-integrated as it al-

ready provides hard-coded method guidance to the

engineers and thus the process engine guidance was

limited.

3.2 Extended Metamodel

Our goal was to extend our original PRIME process

metamodel and integrate it with workflow elements

according to our aforementioned integrated modelling

approach. To this end, we adapted metamodel exten-

sions according to the Workflow Management Coali-

tion (WfMC) Standard (WfMC, 2001). WfMC has

developed specifications for standards that concen-

trate common characteristics of workflow manage-

ment products. As a result, these specifications im-

prove the opportunities for the effective integration

of commonly used workflow concepts and thus pro-

mote the interoperability with other workflow prod-

ucts. The resulting metamodel is shown in figure 4.

The existing NATURE metamodel is shown at the

lower part of the figure and is divided by a dotted line

with the adapted extensions shown at the upper part.

Following the WfMC reference metamodel, the

pieces of works that have to be done are captured in

the activity. An activity represents a logical unit of

work that requires the support of human and/or ma-

chine resources for its execution. An activity can be

arbitrary complex and be iteratively composed of oth-

ers until the basic activity level is reached. In our ex-

tended metamodel we call the activities tasks in order

to emphasize their assignment to human actors.

Task Role

asssigned to

Actor

plays

Team

member of

Enterprise

belongs to

consumes/

transforms/

produces

employs

Tool

Product

isa

isa

Mapping

Semanitcs

Context

Situation Intention

Plan

Context

Executable

Context

Choice

Context

isa

isa

isa

related situation related intention

composed of

provides alternatives of

Product

based on

applied

by

Action

changes

Tool

displays

intention of

Command

Element

provides

command element

provides

displays product

composed of

Figure 4: Extended environment metamodel.

A task provides the virtual world inside which

method guidance according to method definitions is

provided. Thus, it makes sense to create a seman-

tic mapping between tasks and NATURE-based con-

texts reflecting the methods. This mapping (first se-

mantic bridge) represents the methods that define the

legal ways of working of a human actor during the

enactment of a task. The mapping may also be carry-

ing some semantics for providing important shared

knowledge such as time scheduling information, a

partial order in the engineering contexts or even de-

fine the contexts that signal the beginning or the ter-

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

258

mination of the task execution.

While a task is being executed, it produces, con-

sumes and transforms products. The products pro-

duced by a task are characterized as output products

of the task, and the products consumed are character-

ized as input products. Input products of a task can be

either existing products from other project sessions or

output products of other predecessor tasks. On the

task level, the products are considered as documents

flowing from one task to the other. On the contextual

level, the structure of the products is detailed to allow

methods to change their properties. As a result, an

isA relationship exists among them (second semantic

bridge).

Each task requires a number of resources in order

to be carried out. Resources include primarily the hu-

man actors assigned to them, their enterprise settings

and the employed tools. Actors are indirectly associ-

ated to their assigned tasks via their roles. Roles are

distributed according to the knowledge background,

skills and assigned responsibilities of the actors play-

ing them. Actors can be divided into teams belong-

ing to enterprises, that work synergetically for the

achievement of a common goal. Since method guid-

ance is provided directly to a specific actor who is

performing a specific task at a specific workplace, the

resources considered on this level are restricted to the

involved tools. Similarly to the case of products, tools

on the method guidance level are detailed with re-

spect to their capabilities and an isA relationship is

also here deduced (third semantic bridge)

With the above metamodel extensions and the three

semantic bridges, we have managed to increase the

PRIME awareness of the more coarse-grained levels

of process execution. As a consequence, PRIME is

able to extend its method guidance mechanism for the

inter-activity support of different human actors. The

benefits of our approach are illustrated on a small case

study in the next section.

4 CASE STUDY

In this section, we detail a small example based on a

case study from the IMPROVE project that illustrates

the benefits of our approach. For the reasons of sim-

plicity and understandability, we use a small and sim-

plified fragment from our overall polyamid6 scenario.

Polyamid6 is produced from monomer chemical

plants. The design process consists of three promi-

nent process steps: reaction, separation and com-

pounding. We are going to focus on the compound-

ing phase. The compounding process modifies the

polymer in order to give it some desired characteris-

tics (such as heat resistance and mechanical stability).

Two expert roles contribute to this process: the com-

pounding expert and the 1D-simulation expert. The

main task of the compounding expert, is the concep-

tual configuration of the compounding extruder in-

side the process-integrated flowsheet editor. The re-

sulting configuration is further analyzed by the 1D-

simulation expert who simulates the compounding ex-

truder configuration based on physical and mathemat-

ical models.

Because of the integrated workflow extensions,

PRIME is able to further apply coordination and

method guidance outside of the frontiers of a specific

task. Process engine is aware of the interconnected

tasks and through the semantics of the mapping of

contexts to activities, contexts signaling the beginning

or the termination of a task can be known. Thus, in

the case of a need of control and data flow among two

activities, the terminating context of the first task, can

be coupled with the beginning context of the second

through a plan context and the data transfer can be

realized under the support of the process engine.

Export to MOREX

Export Extruder

Configuration

Import Extruder

Configuration

(plan context)

(executable context)

(executable context)

extruder configuration

composed of

mapped to

mapped to

mapped to

Design of

Compounding Elements

1D-Simulation of

Compounding Process

Compounding Expert

d

i

s

p

l

a

y

o

f

i

n

t

e

n

t

i

o

n

1D-Simulation Expert

Flowsheet Editor

MOREX

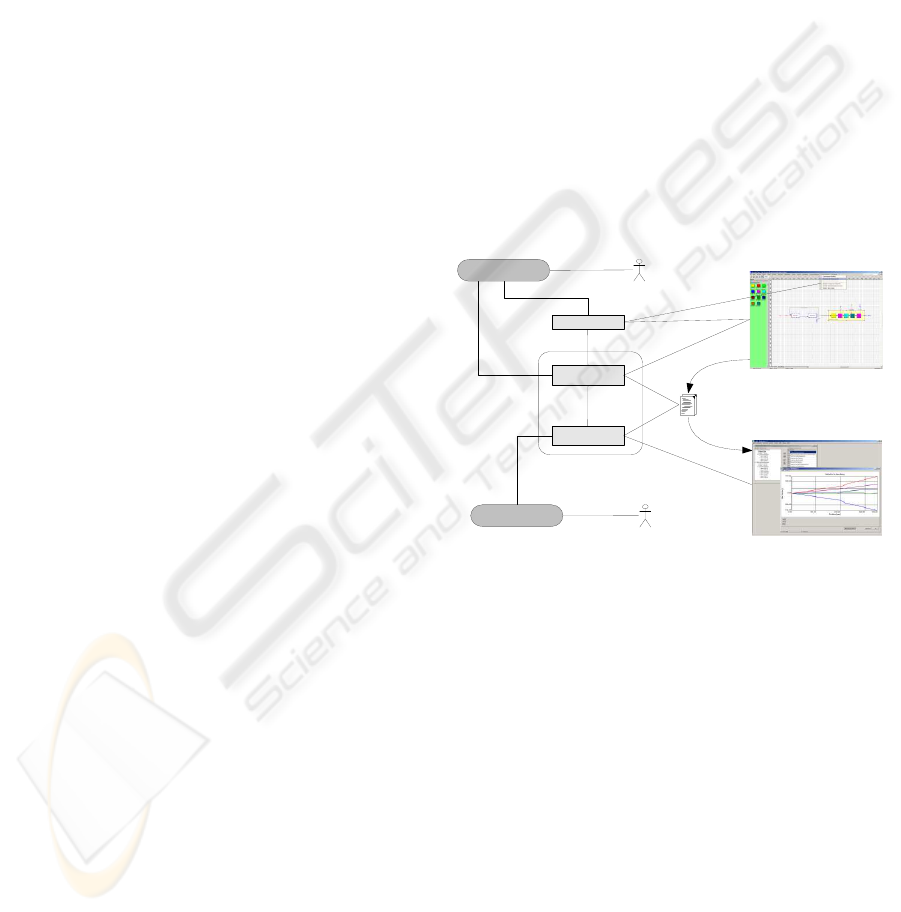

Figure 5: Example of inter-activity method guidance.

Figure 5 shows a UML-like diagram of the transi-

tion from the ‘Design of Compounding Elements’ task

of the compounding expert to the ‘1D-Simulation of

Compounding Process’ task of the 1D-simulation ex-

pert. The compounding expert is invoking the ‘Ex-

port to MOREX’ plan context through a menu item

in the flowsheet editor. This plan context defines the

strategy (steps) for the transition. The first step is

the executable context ‘Export Extruder Configura-

tion’, applied automatically by a flowsheet editor ac-

tion, that exports the extruder configuration to XML

format. The next step is the ‘Import Extruder Con-

figuration’ executable context applied by a MOREX

action in the workplace of the 1D-simulation role. It

receives the exported extruder configuration and im-

ports it in MOREX creating a new project configura-

tion. Now the expert can modify the properties of the

received extruder if needed and start the simulation.

INTEGRATING WORKFLOW EXTENSIONS INTO A PROCESS-INTEGRATED ENVIRONMENT FOR CHEMICAL

ENGINEERING

259

5 CONCLUSIONS AND

OUTLOOK

In this paper we presented the extensions applied to

a PRIME-based environment for supporting chemical

engineering design processes. Initially this environ-

ment was capable of providing intra-activity situated

method guidance i.e. at a specific engineering work-

place. Motivated by the integration trends in modern

enterprises, we developed a modelling approach ex-

tending our existing fine-grained process models and

integrating it with the more coarse-grained level of

workflow activities. This integration was achieved us-

ing the three introduced semantic bridges. As a con-

sequence, the gap between the workflow management

level and the method guidance level was narrowed. A

better understanding of the full granularity spectrum

of the executed processes was achieved and our en-

vironment was able to further provide inter-activity

method guidance to various engineers.

Our adapted integrated modelling approach, con-

centrates two viewpoints on our executed processes.

On the method guidance level, our contextual process

model captures method fragments and thus views

processes ‘in the small’. On the workflow manage-

ment level, on the other hand, a broader view is taken

decomposing processes to well-defined tasks. In the

near future, we are planning to investigate ways of

further capturing inside our underlying models the

intermediate level of methods as assemblies of our

stored method fragments (Ralyt

´

e and Rolland, 2001).

Further future work is planned to address the area

of interoperability of our integrated environment with

other external components of the IMPROVE inte-

grated design environment. In particular, we are in-

terested to integrate our fine-grained method guid-

ance environment with the AHEAD reactive adminis-

tration system developed for the coarse-grained man-

agement of design processes (Westfechtel, 2001).

Our main goal is to enable AHEAD to directly

call the PRIME process engine services such as di-

rect manager-triggered invocations of specific process

fragments and to get back notifications concerning the

execution status of activities.

ACKNOWLEDGEMENTS

This work was carried out in the Collaborative Re-

search Center 476 IMPROVE which is funded by

the Deutsche Forschnungsgemeinschaft (DFG). We

would like to thank Christoph Quix, Sebastian Brandt

and Marcus Schl

¨

uter for their valuable contributions

to our work.

REFERENCES

Bayer, B., Marquardt, W., Weidenhaupt, K., and Jarke, M.

(2001). A flowsheet centered architecture for concep-

tual design. In ESCAPE-11.

Becker, S., Haase, T., Westfechtel, B., and Wilhelms, J.

(2002). Integration tools supporting cooperative de-

velopment processes in chemical engineering. In Intl.

Conf. Integrated Design and Process Technology.

Cardoso, J., Bostrom, R. P., and Sheth, A. (2002). Work-

flow management systems vs. ERP systems: Differ-

ences, commonalities, and applications. Technical re-

port, University of Georgia.

ISO/IEC (1990). Information technology - information

resource dictionary systems (IRDS) - framework.

ISO/IEC international standard.

Jarke, M., List, T., and K

¨

oller, J. (2000). The challenge of

process data warehousing. In 26th Intl. Conf. on Very

Large Databases, pages 473–483.

Jarke, M., List, T., and Weidenhaupt, K. (1999a). A

process-integrated conceptual design environment for

chemical engineering. In ER, pages 520–537.

Jarke, M., Rolland, C., Sutcliffe, A., and D

¨

omges, R., ed-

itors (1999b). The NATURE of Requirements Engi-

neering. Shaker Verlag.

Nagl, M. and Westfechtel, B., editors (1998). Integration

von Entwicklungssystemen in Ingenieuranwendungen.

Springer-Verlag.

Nuseibeh, B. and Finkelstein, A. (1992). Viewpoints: A

vehicle for method and tool integration. In 5th Inter-

national Workshop on Computer-Aided Software En-

gineering.

Pohl, K., Weidenhaupt, K., D

¨

omges, R., Haumer, P., Jarke,

M., and Klamma, R. (1999). PRIME - toward process-

integrated modeling environments. ACM Trans. Softw.

Eng. Methodol., 8(4):343–410.

Ralyt

´

e, J. and Rolland, C. (2001). An assembly process

model for method engineering. In 13th International

Conference on Advanced Information Systems Engi-

neering.

Schl

¨

uter, M. and Haberstroh, E. (2002). Design of twin

screw extruders with the MOREX simulation soft-

ware. In PPS.

van der Aalst, W. and van Hee, K. (2002). Workflow Man-

agement. The MIT Press.

Vernadat, F. B. (1996). Enterprise Modeling and Integra-

tion - Principles and Applications. Chapman and Hall.

Westfechtel, B. (2001). AHEAD: A graph-based system

for modelling and managing development processes.

Informatik Forsch. Entw., 16(3):125–144.

WfMC (2001). The Workflow Management Coalition Spec-

ification (http://www.wfmc.org).

zur Muehlen, M. and Rosemann, M. (2004). Multi-

paradigm process management. In Proceedings of

CAiSE’04 Workshops - 5th Workshop on Business

Process Modeling, Development and Support.

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

260