A SURVEY OF CASE-BASED DIAGNOSTIC SYSTEMS FOR

MACHINES

Erik Olsson

Departmant of Computer Science and Electronics, Mälardalen University, Västerås, Sweden

Keywords: Case-Based Reasoning, Fault Diagnosis, Artif

icial Intelligence, Machine Learning, Neural Networks.

Abstract: Electrical and mechanical equipment such as gearboxes in an industrial robots or electronic circuits in an

industrial printer sometimes fail to operate as intended. The faulty component can be hard to locate and

replace and it might take a long time to get an enough experienced technician to the spot. In the meantime

thousands of dollars may be lost due to a delayed production. Systems based on case-based reasoning are

well suited to prevent this kind of hold in the production. Their ability to reason from past cases and to learn

from new ones is a powerful method to use when a failure in a machine occurs. This enables a less

experienced technician to use the proposed solution from the system and quickly repair the machine.

1 INTRODUCTION

This paper addresses case-based reasoning (CBR)

(Aamodt, Plaza. 1994) systems used for diagnosis of

machines. The paper is intended to give the reader a

survey of CBR systems in this area. The particular

systems in this survey were chosen because of their

well-documented CBR-part (Pous et. al. 2004) and

their application in the area of machine diagnosis.

All systems in this survey were created or reported

after about 1999 and are published in major

Proceedings and Journals such as the ECCBR and

ICCBR Proceedings and Journal of Intelligent and

Fuzzy Systems.

The paper is structured as follows: Section 2

gi

ves an overview of five CBR diagnostic systems

for machines. Section 3 discusses and compares

features of the systems. Section 4 gives a brief

conclusion of the systems.

2 THE SYSTEMS

This section describes five CBR systems for

diagnostics of machines. The first system is a

diagnostic system for locomotives. It collects fault

codes from locomotives and uses them for off-board

locomotive diagnosis. The second system diagnoses

electric circuits. It uses measurement data from the

circuit as features and matches them with similar

cases. The proposed solution is then adapted to the

new case. The third system monitors the health of

satellites by looking for anomalies in the down

linked data from the satellite. The fourth system

diagnoses industrial robots with the aid of acoustic

signals. The fifth system uses a combination of a

neural network and CBR to diagnose induction

motors.

2.1 ICARUS – A Diagnostic System

for Locomotives

Locomotives are large and complex machines that

are very difficult and expensive to repair. Due to

their complexity, they are often best served and

repaired by their manufacturer. The manufacturer

often have a long time service contract with their

customers and it is important for the manufacturer to

reduce the service costs as much as possible.

ICARUS (Varma, 1999) is a case-based

reasoning tool for off-board locomotive diagnosis.

Locomotives are equipped with many sensors that

can monitor their state and generate fault messages.

ICARUS is designed to handle the fault codes that

are generated by the locomotives.

Each fault code is saved in a fault database.

Connected to

each fault is a repair log taken from a

repair database. The fault log combined with the

repair log is a case in ICARUS.

Most repair logs contains a fault cluster. This

mean

s that many small faults occur before a repair is

performed. The cluster of faults is used as features

381

Olsson E. (2005).

A SURVEY OF CASE-BASED DIAGNOSTIC SYSTEMS FOR MACHINES.

In Proceedings of the Seventh International Conference on Enterprise Information Systems, pages 381-385

DOI: 10.5220/0002522003810385

Copyright

c

SciTePress

for case matching. Each cluster is assigned a weight

between 1 and 0. The value of the weight is set to

represent a clusters ability to isolate a specific repair

code. If a cluster is connected to only one repair

code it’s weight will be 1. If a cluster is connected to

evenly distributed repair codes in the case base it’s

weight will be lower. Clusters below a certain

weight threshold will be assigned zero weights.

The weights are used in the matching formula.

The degree of likeness between a new case and as

stored case is calculated as:

[

[][

]

]

∑∑

∑

× casenewweightsclustersofweights

casenewandstoredbetweencommoninweights

in clusters of case storedin

2

clusters

The repair code associated with the case with the

highest degree of likeness is the retrieved case.

The system vas validated with a case base

consisting of 50 repair codes. Each repair code was

associated with 3-70 cases. Each case was removed

from the case base and matched to all other cases in

the case base. If the repair code of the case was in

the top three nearest neighbouring cases, the match

was considered as a success. As a result the overall

accuracy of the system was 80%.

2.2 Diagnosis of Electronic Circuits

Diagnosis of electronic circuits is based on the

analysis of the circuit response to a certain input

stimuli. Input signals are generated and

measurements are acquired in certain nodes of the

circuit. A traditional way of doing this is to use fault

dictionaries. Fault dictionaries are based on selected

measurements on faulty systems. The comparison is

performed by a nearest neighbour calculation and

the closest case is taken as a diagnosis. The problem

with fault dictionaries occurs when a new fault is

found that cannot be matched with the ones already

stored in the dictionary. To deal with this a case-

based approach is suitable to be able to

automatically extend the dictionary with new faults

as they occur (Pous et. al. 2004).

The case consists of two parts. Part one is the

numeric part that contains the case identification

number and the measurements taken from the

circuit. The second part contains information about

the fault diagnosis.

Table 1: Case structure. The measurement part

Case id Measure1 Measure2 … MeasureN

Case i M1 M2 … MN

Table 2: Case Structure Fault Part

Class Comp. Deviation Hierarchy

Class i Comp. i X% L

i

M

i

The class corresponds to the class of component

that is diagnosed. The components are divided into

different classes if they have different accepted

deviations from their normal value. E. g. +/-10% can

be an accepted deviation for a class of components.

The component field contains the component

location. The deviation field contains the measured

deviation of the component. The hierarchy field

contains a description of witch level in the circuit

hierarchy the components is.

A normalized Euclidian distance function is used

to retrieve the cases from the case base and the k

nearest neighbours where k=3 is retrieved. The

solution is adapted to the new case by

transformational reuse (Aamodt, Plaza. 1994). A

learning algorithm is then applied to decide whether

the case should be saved as a new case in the case

base or not. E.g. if the diagnosis is correct there is no

need to retain the new case in the library. But if the

retrieved cases produce a misclassification of the

new case, the case might be added to the case base

according to the results of the learning algorithm.

The system has been tested with the DROP4

(Wilson, Martinez. 2000) and the All-KNN learning

algorithms. All cases are also equipped with weights

to improve the classification.

A measurement on a circuit is performed

resulting in the k=3 nearest neighbors in table 3.

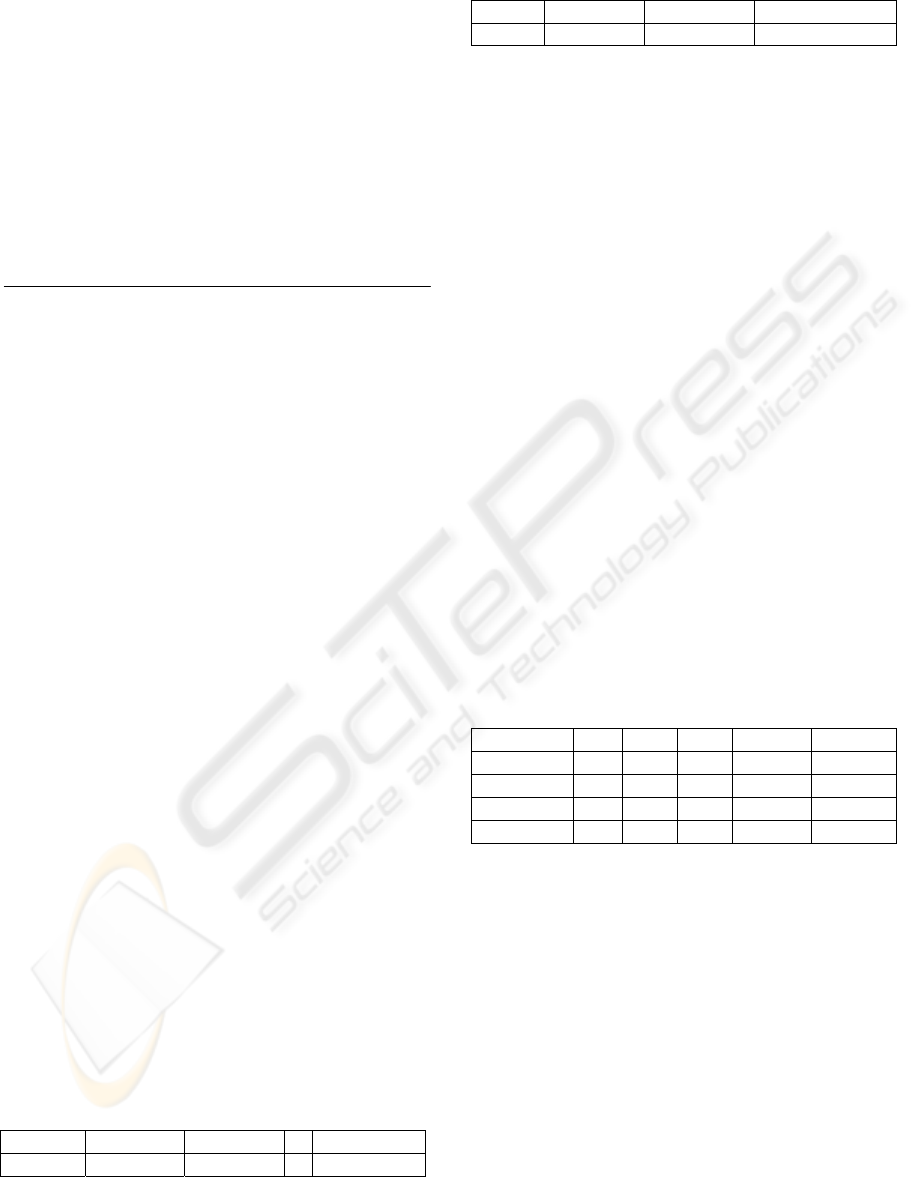

Table 3: An example of a case retrieval

M1 M2 M3 Comp Devi

New Case 0.6 0.7 1.2 C

1

75

Neighbor1 0.6 0.7 1.1 C

1

23

Neighbor2 0.7 0.4 1.3 C

1

24

Neighbor3 0.7 0.4 1.3 C

2

11

Neighbour 1 and 2 has the same component as

the new case but the deviation is smaller in both

cases. Neighbour 3 has a different component. The

new case will be selected as a component C

1

because

of its similarity in the measurements. The deviation

is far from normal so the case will be introduces in

the case base.

The system has been tested on a filter circuit that

is commonly used as a benchmark for electronic

circuits. The filter consists of several capacitors and

resistors. The average result with the All-KNN

retain algorithm was 89% and the average result

with the DROP4 retain algorithm was 88%.

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

382

2.3 Satellite Diagnosis

Satellites are monitored from the ground using down

linked data (telemetry). The case-based diagnosis

program can be resembled as an expert apprentice.

The program remembers the human experts actions

along with the context that is defined by the down

linked data. It then attempts to make it’s own

diagnosis when similar data appears in another

occasion (Penta, Khemani. 2004).

The features in the case are not state values taken

at a certain point of time. Because of the telemetry’s

streaming values the features are instead trends

extracted from the streaming data flow. The length

of the trend is different for different parameters. The

table below shows a sample case with two

parameters:

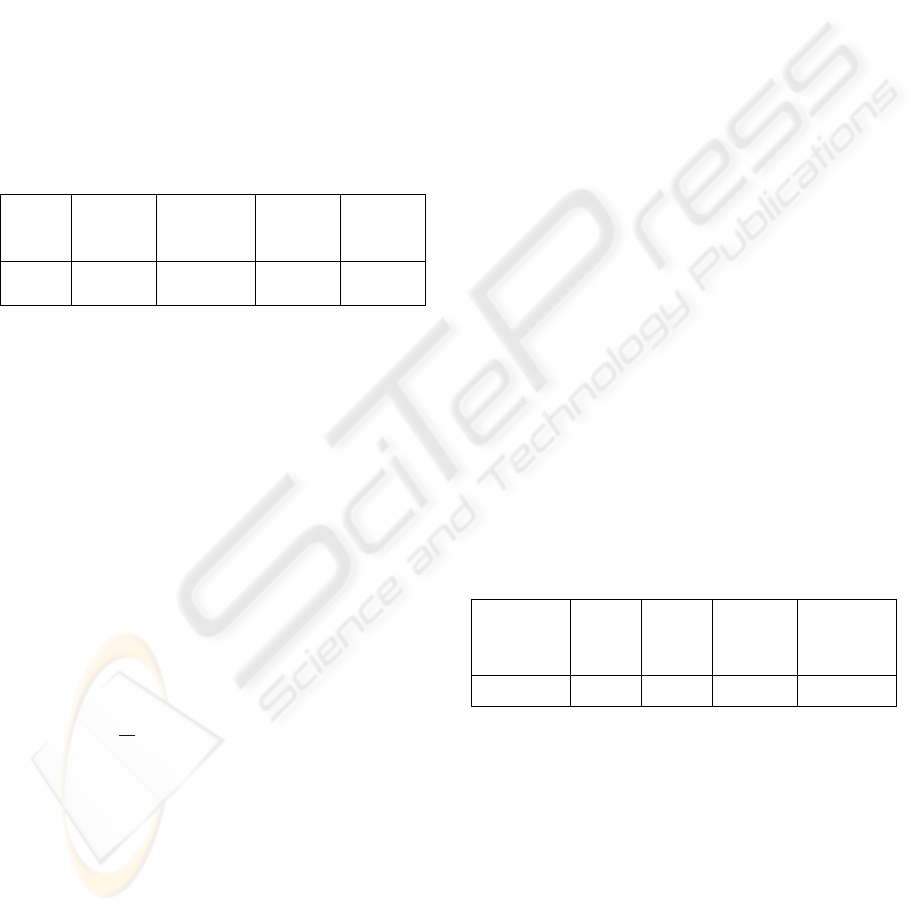

Table 4: Case structure of a satellite case (problem part)

Case

id

Length

of time

series

Sampling

rate

Lower

bound

Upper

bound

1234

2345

1000

2000

45

60

-3

0

10

10

A case is constructed from the streaming data at

a time called the case point. A case is constructed

looking back from the case point a certain length of

time. The attribute values are picked using a window

of the same length as the sampling rate. For each

window only one average value is saved as

representing that window. The length of the time

series corresponding to an attribute is l/s were l is

the length specified in the case schema and s is the

sampling rate.

The distance between two time series R, W is

calculated by dividing the time series into smaller

sequences R

i

, W

i

. An Euclidian distance calculation

between each R

i

, W

i

is performed and a global

distance d

g

is calculated from all the obtained

distances between the time series sequences. See (1).

),(

1

),(

1

ii

k

i

ig

WRd

k

WRd

∑

=

= (1)

The system notifies the user if a new case is

considered interesting. The new case is considered

interesting it two ways.

1. A similarity threshold ε determines if the

new case should be considered as an

anomaly. If the similarity of all the

retrieved cases is below that threshold the

case is considered to be an anomaly and the

user is automatically notified.

2. If some of the retrieved cases are above the

first threshold. Another threshold

determines if the new case is similar

enough to some other case in the case base

that is previously diagnosed as an anomaly.

If so the system will notify the user of the

type of anomaly. In both situations the user

is able to give feedback to the system.

2.4 Diagnosis of Industrial Robots

Mechanical fault in industrial robots often show

their presence through abnormal acoustic signals.

At the factory end test of industrial robots a

correct classification of the robot is very critical. An

incorrect classification of a faulty robot may end up

in the factory delivering a faulty robot to the

customer.

The industrial robot diagnosis system uses case-

based reasoning and acoustic signals as a proposed

solution of recognizing auditable deviations in the

sound of an industrial robot (Olsson et. al. 2004).

The sound is recorded by a microphone and

compared with previously made recordings; similar

cases are retrieved and a diagnosis of the robot can

be made.

Features are extracted from the sound using

wavelet analysis (Bachman, 2000). A feature in the

case is a normalized peak value at a certain

frequency. The case contains peak values from many

frequencies. The case also contains fields for

information of the robot model and type of fault (if

any). There is also room to enter how the fault was

repaired. Table 5. displays a part of the case

structure.

Table 5: A part of the case structure for robot diagnosis.

Serial

Number

Type Fault

Diagnos

is and

Repair

Features

1-n

45634 4500 2 … …

Cases are retrieved using a nearest neighbour

function that calculates the Euclidian distance

between the new case and the cases stored in the

case library. A list with the k nearest neighbours is

retrieved based on the distance calculations. The

system learns by adding new cases to the case base.

A technician enters the diagnosis and repair action

manually in each case.

The system has been evaluated on recordings

from axis 4 on an industrial robot. Sounds from 24

healthy robots and 6 faulty robots were colleted to

enable case-based classification of the condition of

the robots. The prototype system demonstrated quite

A SURVEY OF CASE-BASED DIAGNOSTIC SYSTEMS FOR MACHINES

383

good performance by making right judgments in

91% of all tests.

2.5 Induction Motor Fault Diagnosis

Induction motors are very common within industry

as prime movers in machines. Induction motors has

a simple construction and are very reliable. But

working in a tough environment driving heavy loads

can introduce various faults in the motors. A system

for fault diagnosis of induction motors is presented

here. The system has interesting features such as a

neural network combined with a case-based

reasoning system (Yang et. al. 2004).

A case consists of 6 categories of features and 20

variables. Among the variables are measurement

positions, rotating frequency components and

characteristic bearing frequencies. The case also

includes the type of machine to be measured, the

symptom, the corrective action etc.

The system uses an ART-Kohonen neural

network (Carpenter, Grossberg. 1988) (ART-KNN)

to guide the search for similar cases in the case base.

CBR is used to select the most similar match for

a given problem. The advantage with the ART-KNN

compared to other neural networks such as the

Kohonen Self Organizing Map (Kohonen, 1995) is

that it can learn new knowledge without losing old

knowledge. When a new case is presented to the

system the ART-KNN learns the new case in one of

two ways:

1. If the similarity of the new case compared

to the cases already learned by the network

is below a certain threshold; the similarity

coefficient. The network learns the case by

adding new nodes to its layers.

2. If the similarity of the case is above the

threshold, the network learns the case by

adjusting its old nodes to resemble the new

case.

Cases are then indexed in the case base by

clusters of features in the ART-KNN. The indexed

cases are then matched against the new case with a

standard similarity calculation.

The system has been tested with measurements

from an AC motor in a plant. The motor had a rotor

fault witch resulted in high levels of noise and

vibration. The system was trained with 60 cases

containing different motor defects such as bearing

faults, rotor damages and component looseness.

The system retrieved two previous cases from the

case base together with results from a modified

cosine matching function. The retrieved cases both

indicated a bearing fault. The average result of a test

of all cases in the case base was 96,88%.

3 DISCUSSION

When comparing different case-based reasoning

systems with each other one must focus on the

features that are shared by all case-based reasoners.

Below is a comparative discussion of five

common problems that has to be faced when

implementing a case-based reasoner and how they

are solved in each system. The problems are as

follows:

1. Feature extraction and case representation.

2. Case retrieval and indexing.

3. Case reuse.

4. Case revision and retain.

5. Case base maintenance.

1. ICARUS uses combinations of fault codes as

features because that is the way a locomotive signals

its faults. A repair action on a locomotive is also

very expensive, thus several faults must be

combined before a repair action can be executed.

Often machines cannot provide such fault codes.

Instead features such as filtered measurements from

different kinds of sensors are used. This is the

situation for the electronic circuit diagnosis system,

the induction motor diagnosis system, the satellite

diagnosis system and the industrial robot diagnosis

system. They all collect single measurements or time

series measurements, e.g. current, vibration, acoustic

signals, streaming telemetry data etc. The data

collecting sensors can be an integrated part of the

object or an external portable measurement device.

The basic case representation is similar for the

systems in this survey. The three basic components

of the case are the features, the problem description

and the repair action. Sometimes the repair action is

implicit in the fault description. As in the electronic

circuit diagnosis system, the repair action is equal as

to replacing the faulty component.

2. The case retrieval process most commonly uses

some kind of distance calculation combined with

weights to calculate a distance between the new and

stored cases. The k nearest neighbours to the new

case is then retrieved. This kind of retrieval is used

in all systems except the induction motor diagnosis

system and the satellite health diagnosis system. The

satellite health diagnosis system uses two similarity

thresholds; one for anomaly detection and one for

event detection. The induction motor diagnosis

system uses a neural network to first index relevant

cases in the case base. After that a straightforward k

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

384

nearest neighbour distance calculation is performed

to calculate the distance between the indexed cases

and the new case.

3. All systems in this survey implements the

reuse phase by suggesting the diagnosis extracted

from the retrieved k nearest neighboring cases. The

satellite diagnosis system also has a threshold for

sorting out irrelevant cases not to be considered for

reuse. In addition to this form of reuse the circuit

diagnosis system uses adaptation (Aamondt, Plaza.

1994) by transforming the past solution of the k=3

nearest neighbors to an appropriate solution for the

new case. The new solution is then inserted into the

new case as the proposed solution.

4. The simplest form of retaining is to just add the

new case in the case base. The industrial robot

diagnosis system uses this kind of retaining (the

robot diagnosis case base is then manually

investigated by an experienced technician in order to

remove irrelevant cases and provide relevant cases

with more diagnostic information). To few removals

of cases can in time cause problems with an

overfilled case base making the system perform less

well. Most system implements some kind of user

interaction before a case is retained. This is

performed in the satellite diagnosis system and in

ICARUS by letting an experienced technician decide

whether the case is relevant or not. The retaining

process can be extended by calculating if the new

case has any ability to improve the future diagnosis

of the system. The simplest form is to look if a

similar case already exists in the case base. If it

does, there is no need to retain the case. The circuit

diagnostic system also incorporates a machine-

learning algorithm that calculates the ability of the

case to improve the performance of the system.

5. Most systems in this survey are only

prototypes and have not yet implemented any

automatic maintenance process of the case memory.

The circuit diagnosis system implements a

confidence factor (Aha et. al. 1991) to prevent bad

cases from spoiling the performance of the system.

The case base is maintained by removing cases

when the performance of the case drops below a

certain confidence index.

4 CONCLUSIONS AND FUTHER

WORK

This paper has briefly described five intelligent

machine diagnostic systems that use case-based

reasoning as their primary approach to problem

solving. Case-based reasoning is still new in the area

of fault diagnosis of machines and most systems in

this survey are still prototypes. Some parts of the

CBR process seem to be implemented to a higher

extent than others in the systems. E.g. feature

extraction and case retrieval seems to be fully

implemented but adaptation is not widely

implemented. Also, automatic maintenance of the

case memory seems not to be implemented in the

majority of the systems in this survey.

REFERENCES

Aamodt, A., Plaza, E. (1994). Case-based reasoning:

Foundational issues, methodological variations, and

system approaches. AI Communications 7, pages 39-

59.

Aha, D.W., Kibler, D., Albert, M. (1991) . Instance based

learning algorithms. Machine Learning. 6, pages 37–

66.

Bachman, G., (2000). Fourier and Wavelet Analysis.

Springer, New York.

Carpenter, G. A., Grossberg, S. (1988). The art of adaptive

pattern recognition by a self-organizing neural

network. IEEE Transactions on Computer 21, pages

77–88.

Kohonen, T. (1995). Self-organizing maps. New York:

Springer-Verlag.

Olsson, E., Funk, P., Xiong N. (2004). Fault Diagnosis in

Industry Using Case-Based Reasoning. Journal of

Intelligent & Fuzzy Systems, Vol. 15.

Penta, K.K. Khemani, D. (2004). Satelllite Health

Monitoring using CBR Framework. Advances in

Case-Based Reasoning. Seventh European

Conference, pages 732-747.

Pous, C., Colomer, J. Melendez, J. (2004). Extending a

Fault Dictionary Towards a Case Based Reasoning

System for Linear Electronic Analog Circuits

Diagnosis. Advances in Case-Based Reasoning.

Seventh

European Conference, pages 748-762.

Varma, A. (1999). ICARUS: Design and Deployment of a

Case-Based Reasoning System for Locomotive

Diagnostics. Case-Based Reasoning Research and

Development: Third International Conference on

Case-Based Reasoning, ICCBR-99, Proceedings,

pages 581-596.

Wilson, D., Martinez, T. (2000). Reduction Techniques

for Instance-based Learning Algorithms.

Machine Learning 38, pages 257–286.

Yang, B., Han, T., Kim, Y. (2004). Integration of ART-

Kohonen neural network and case-based reasoning for

intelligent fault diagnosis. Expert Systems with

Applications 26, pages 387–395.

A SURVEY OF CASE-BASED DIAGNOSTIC SYSTEMS FOR MACHINES

385