HOW TO VALUE AND TRANSMIT NUCLEAR INDUSTRY

LONG TERM KNOWLEDGE

Anne Dour

g

non-Hanoune

EDF R&D, 6 quai Watier, 78401 Chatou cedex, France

Eunika Mercie

r

-Lauren

t

EML Knowledge Management & Innovation, 620 Chemin des Grives, 34160 St Drezery, France

Christophe Roche

University of Savoie, team Condillac, Campus scientifique 73376 Le Bourget du Lac cedex, France

Keywords: Ontology, Knowledge Manag

ement, Common language

Abstract: The French nuclear industry deals with technologies which will soon be thirty years old. If such

technologies are not renewed they must last for another ten years- or more if the decision is taken to keep

them working. There is a risk of technological obsolescence- something which is allowed for in other

national and international projects. There is also the question of constant commercial demand- something

also considered elsewhere in establishing contracts. Another problem is now beginning to emerge; the

continuity and transmission of knowledge and experience concerning these plants. Personnel in the energy

sector are being renewed. Most current employees are due to retire in the course of this decade. How is

knowledge (both of maintenance and planning) to be transmitted to the new generations ? This knowledge

includes written information but also know-how and implicit working assumptions; expertise, experience,

self-learning. In the United States the EPRI produced a technical dossier [EPRI 1]. The problem of

knowledge of old technologies is therefore recent, but almost universal. As far as EDF knows, nobody is

considering this subject in its entirety. Instead, each technology puts the emphasis on operation (and thus

safety) according to a fixed timetable (ten-year visits, end of use). In this perspective the initial knowledge

can be lost. It can happen, for example, that the need for renewal can oblige the agency to carry out a costly

or difficult retro-engineering project so as to recover the original knowledge and technology. If we look

ahead, the policy of long term development (notably extending the life of plants) requires us to consider the

life-span of the different skills and knowledge required by each environment. So it is necessary to take into

account the entire life cycle of a nuclear installation. We are working on organizing all this knowledge and

building an innovating solution for easy acquisition, access and sharing knowledge and experiences. First

we are creating an ontology-based common language for all involved and defining some applications on

Intranet. Ontology, understood as an agreed vocabulary of common terms and meanings shared by a group

of people, is a means for representing craft concepts upon which knowledge can be organised and classified.

We shall present one of the first applications based on the Logic Diagrams Designer's ontology whose main

goals are to keep in memory the craft knowledge about relay circuits schemas and to allow accessing and

retrieval information. This choice of ontology as a basis provides an easy and relevant navigation, indexing

and search of documents...

1 INTRODUCTION

The French electricity generation capacity includes

58 PWR nuclear plants in operation, in 3 power

levels (900 MW, 13000 MW and 1450 MW) and 6

reactor types, that is of the same design.

In terms of life cycle management, the EDF general

strategy

is to operate nuclear power plants for 40

years at least. For a operating life of 30 years, the

personnel who took part in the design and

commissioning of units are still with EDF, which

will not be the case for much longer. With time,

modifications to units become increasingly

323

Dourgnon-Hanoune A., Mercier-Laurent E. and Roche C. (2005).

HOW TO VALUE AND TRANSMIT NUCLEAR INDUSTRY LONG TERM KNOWLEDGE.

In Proceedings of the Seventh International Conference on Enterprise Information Systems, pages 323-326

DOI: 10.5220/0002512303230326

Copyright

c

SciTePress

significant and may lead to partial redesign, which

requires total mastery of the design and justifications

of the choices made. The ageing management

programme includes therefore a long-term

maintenance of knowledge approach to "pass the

baton" to those generations who did not take part in

the original design choices or construction.

This problem is shared with other utility companies.

It is covered by the Euratom programme.

In the USA, where the loss of knowledge and of

undocumented know-how has been identified in the

Energy sector, a study [EPRI 1] noted the risk of the

disappearance of knowledge, particularly knowledge

of design and modifications, which concern us here.

It also raises the question of the maintenance of

knowledge of feedback, but this is subject to a

specific organisation in France.

2 THE PROBLEM OF 900 MW NPP

RELAY CIRCUITS

2.1 The I&C of 900 MW power plants

Relay technology is highly significant for

instrumentation and control (I&C) in the oldest

nuclear units of the French reactor stock, the 900

MW nuclear power plants (NPP), where there are

tens of thousands of relay circuits, involved in all

functions. The traceability of documentation (design,

modifications, feedback) has always been very

important.

In so far as design documentation is concerned, it

mainly dates back to end of the 1970's, the period of

construction and commissioning of the 900 MW

power plants. The engineers (operation,

instrumentation, automatic control) who were at the

start of the design of these power plants, are coming

to the end of their careers.

2.2 Knowledge of relay circuits

The first of the players, the operator, has no worries

with relay systems: the relay circuits has not

changed, they have aged a little, but its excellent

reliability has protected it from modifications and

replacements. The documents are as is, hardly ever

amended but often reproduced. The installations

themselves change little, therefore modifications are

rare.

When knowledge is no longer put into practice, it

tends to be forgotten. Therefore, in operation,

knowledge appears to crystallise on components,

boards and relays. The overview of the installation is

less important, the "memory of installations"

(design, modifications) often disappears as

personnel leave.

Engineering offices are the guardians of "the

memory of installations". This memory is in the

extensive and highly diverse documentation

(functional design diagrams, logic specification

diagrams and wiring diagrams …), accessible in

CAD systems. The design of these diagrams is given

in writing, but know-how is transmitted orally,

through training sessions or apprenticeships.

The memory of installations "goes down" to the

memory of equipment. In this case, the combination

is very important, given the large number of

equipment configurations and their use. Once again,

oral know-how of the options adopted during the

design phase and the choice of modifications is

important; it is often heuristics that limit or classify

combination.

Essential knowledge is therefore of two kinds; semi-

formal representation on the one hand (design,

specification, production rules and forms of

representation of diagrams) and, on the other,

practical oral knowledge of the interpretation of

previous knowledge. This is what interests us.

3 CONSTRUCTION OF A

COMMON LANGUAGE

3.1 Our approach

The awareness of this very important combination

and an initial analysis of knowledge has enabled us

to avoid two pitfalls; that of non standardised

modelling [we use standard ISO 704], without a

consistency check, and preliminary, non modifiable

modelling. As we shall see below, we have

linearised the problem by describing it in the form of

a tree-structure and not a graph. This modelling is

incremental and involves all players.

The questions which will be raised over the next 10

years and beyond, are partially unknown. The first

stage for us, ensuring that the knowledge of relay

circuits could make sense later, was to ensure that

they are shared, whatever the situation, profession

and activities of all those concerned, whether in a

context of preserving or renewing technology. The

last pitfall, and not the least, would be not to make

such knowledge independent of the context. We

shall also see how the solution adopted meets this

challenge.

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

324

As in any capitalisation, valorisation and of transfer

of knowledge approach, the first stage consists in

defining, in detail, the trade terminology. That is, the

terms used and their meaning, which constitute a

common language giving access to professional

concepts and the corresponding documentation.

3.2 The Logic Diagrams Designer’s

Ontology

The objectives of consensus, consistency and

sharing for the common language have led us to

choose a solution based on ontology. Ontology as an

agreed vocabulary of common terms and meanings

shared by a group of people, is a means for

representing business concepts according to which

knowledge can be organised and classified.

The profession of the 900 MW Logic Diagrams

Designers that we have adopted for this experiment,

like professions in the nuclear industry in general,

imposes severe restrictions as to the definition of its

terminology: the definition of terms should be

precise and consistent with the logical meaning of

the term. It should also be based on a construction

methodology and can be understood and accepted by

those in the trade, be they experts or novices in

training.

It is for this reason that we have adopted an

ontological approach where professional concepts

are defined by specific differentiation: a professional

concept is defined on the basis of an existing

concept by identifying what distinguishes it.

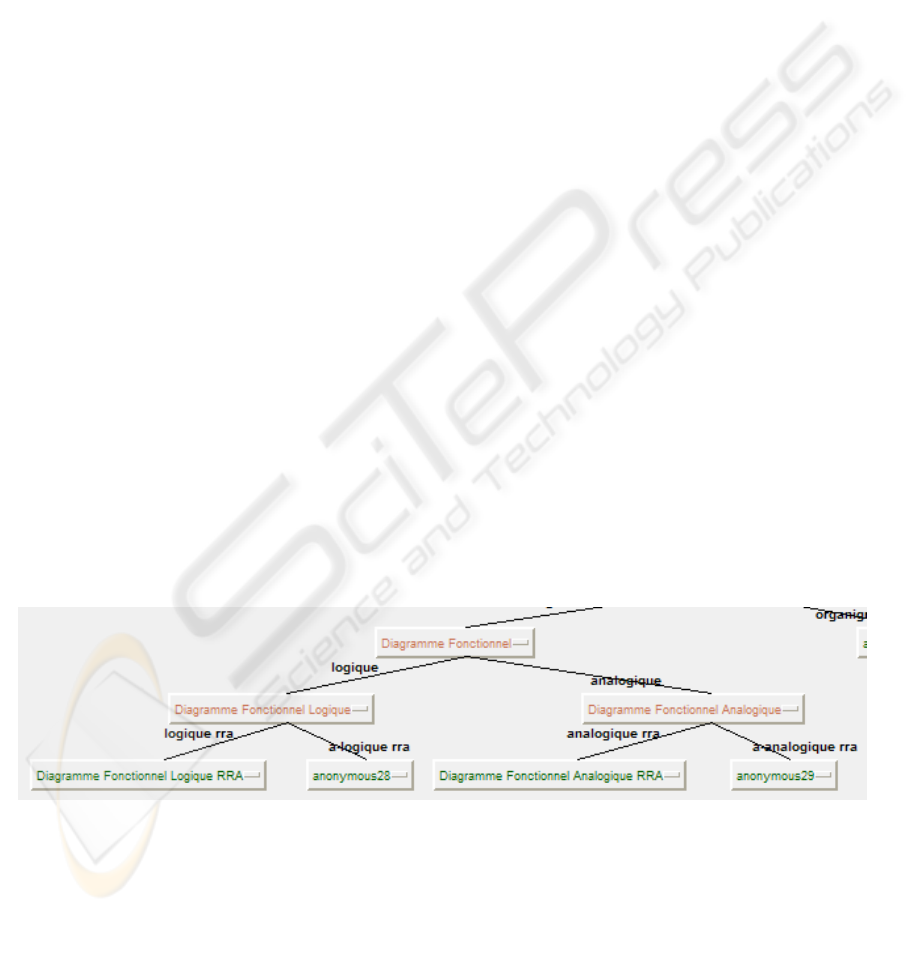

Therefore, a "functional logic diagram" is a

"functional diagram" which is "logical". "Functional

diagrams" are therefore broken down into "

functional logic diagrams" and "analogue functional

diagrams", "logic" and "analogue" being two

specific, opposing differences.

Such an approach has many advantages :

a linguistic base as shown by the structure of

the professional expressions themselves;

an epistemological base: everybody can

agree with the specific-difference definition

where concept A is concept B with the

specific difference d;

no multiple hierarchy and therefore no

problem of inheritance of different values;

sound logical properties which are exploited

during the building of ontology;

last but not least, the agreement problem is reduced

to the sole problem of agreement on the terms that

denote differences. It is all the simpler since the

application field is technical.

3.3 Ontological indexing and retrieval

We have already seen that ontologies may be used to

model and capitalise on professional concepts for

which it is possible to define the terminology for the

field in a precise, consistent and consensual manner.

Ontologies may also be used to index all documents

on the field to such concepts for the purposes of

training but also for finding information.

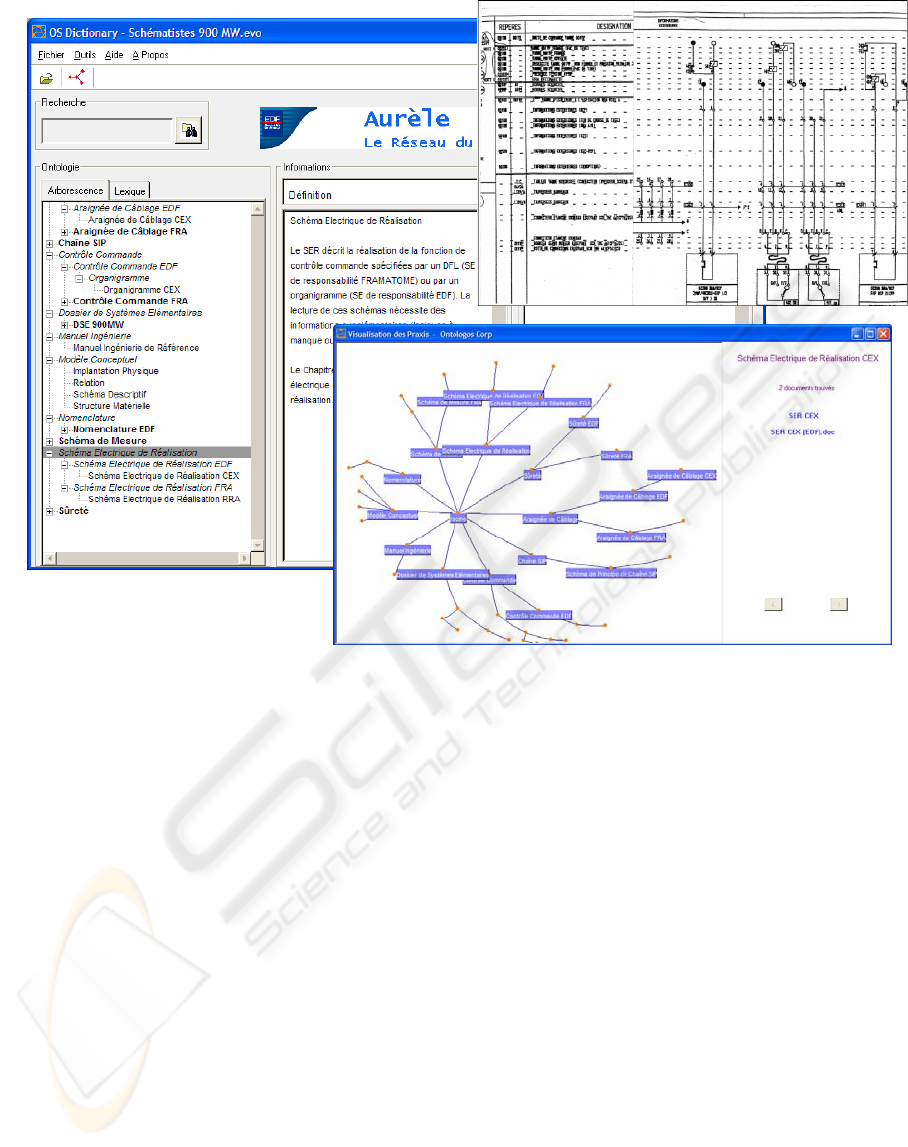

We have therefore created, after defining the

ontology of the Logic Diagrams Designers of 900

MW Relay circuits, an experimental software

environment devoted to terminology on the one hand

and business concepts and, on the other to the search

for and navigation through documents that refer to

such concepts. The figures below illustrate some of

the functions of the software environment accessible

on the EDF intranet.

Functional diagram

Logic analogue

Logic Functional Diagram Analogue Functional Diagram

Rra logic rra a-logic rra analogue rra a-analogue

RRA Functional Logic Diagram anonymous28 RRA Analogue Functional Diagram anonymous29

Fi

g

ure 1: Exam

p

le of an ontolo

gy

HOW TO VALUE AND TRANSMIT NUCLEAR INDUSTRY LONG TERM KNOWLEDGE

325

Fi

g

ure 2: Some of the functions of the software environment

4 CONCLUSION: CAPITALIZING

ON KNOWLEDGE FOR FUTURE

GENERATIONS

Overall flow is created step by step by creating

exchanges which progress from exchanges based on

documents, photographs, glossary to achieve a true

sharing of knowledge and knowledge of equipment,

functional aspects and diagrams.

Our incremental construction approach for a

common solution has the advantage of providing for

virtually automatic acceptance of the system

proposed by all participants and which we have to

validate. This approach is modular and provides for

the gradual construction of a common reference

language.

Ontology is the basis of this language, which enables

us to model knowledge of professions involved in

relay circuits and to ensure appropriate access to

aspects of knowledge, such as documents, diagrams,

photographs, training documents… at the same time.

This language shall form the basis for effective

communication in a global flow knowledge created

by the participation of communities concerned with

relay circuits and others who wish to learn.

REFERENCES

Amidon D.M., Formica P., and Mercier-Laurent E. :

Global Knowledge Innovation at work. (soon)

Ballay J.F. , 1997 : Capitaliser et transmettre le savoir-

faire de l'entreprise, Editions d'Organisation

Ballay J.F. , 2002 : Tous managers du savoir ! , Editions

d’Organisation

EPRI, December 2002 : Capturing high value

undocumented knowledge in the Nuclear Industry. In

Guidelines and methods 1002896 Final report.

Gruber T., 1995 : Towards principles for the design of

ontologies used for knowledge sharing. In:

International Journal of Human Computer Studies, 43:

907-928

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

326