INTEGRATED FEED-FORWARD ARTIFICIAL NEURAL

NETWORKS SYSTEM FOR MACHINES TOOLS SELECTION

Romdhane Ben Khalifa, Noureddine Ben Yahia, Ali Zghal

ESSTT, University of Tunis , 5 Av Taha Hussein, BP.56 Bab Mnara Tunis, Tunisia

Keywords: CAPP, Feed-Forward neural networks, CAD/CAM, machining features, Machine-tools, cutting tools.

Abstract: The choice of the machine tools is one of the considerations of manufacturing companies which depend

primarily on machining process, by deciding how a finished product will be manufactured. The activity of

tools choice is established in geometry of machining features, but it also has a direct impact on workability

and execution of machine-tool. We propose in this paper an integration module of the automatic choice of

machine tools in the environment of systems CAD/CAM, which consisted in the two neuronal systems

NN1 and NN2; NN1 allows the automatic machining machines choice. NN2 makes it possible to choose

cutting tools for machining features. In this work, we have worked two complementary parts for the

integration of the automatic choice of machine tools. Firstly we developed a neuronal system for selection

of machine tools classes. Secondly, we have created an interface of neuronal system integration which

exploits machining features geometrical data to be carried out by Visual Basic programming.

1 INTRODUCTION

By reason of the increasing competition to the world

market, the manufacturing companies always seek

advanced technologies to gain benefit. Indeed, the

total integration of computer-aided design and

computer-aided manufacture (CAD/CAM) were a

goal, for industries as well as for researchers,

towards the realization of the concurrent design of

the products and the process. However, the

automatic machining process planning CAPP

"Computer Aided Process Planning" plays a

significant role in the integrity of CAD/CAM

systems (C. Gologlu, 2004). One of the principal

objectives of the automatic system of machining

process planning is to interpret the information of

design and to prescribe the operations of machining

appropriate and conformed to the conditions

determined by the designer.

More over, the development of the systems by

using the artificial intelligence increased the

diversity of representation of knowledge and

generalization which approaches generative

machining process planning, having as a result the

improved execution of the systems of automatic

machining process planning.

In this research work, we used multi-layer neural

networks for the choice of machines and cutting

tools, starting from information extracted from

machining features.

However, Neural Networks are powerful to

replace the methods of classifications, like their high

speed of resolution and their aptitude of training and

significant adaptation. We have benefited from these

performances to apply neural networks for automatic

choice of machines-tools during the generation of

machining process planning.

The first part of this communication relates to

modeling of the machining features, like their

characteristics. The second part is devoted to the

development of neuronal system structure for the

automatic choice of machine and cutting tools. In the

third part of this communication we will present the

interface of neuronal system integration. We finish

by interpretations of the results of performances of

neuronal system for the automatic choice of

machines and cutting tools starting from a case

study, as well as a conclusion.

161

Ben Khalifa R., Ben Yahia N. and Zghal A. (2005).

INTEGRATED FEED-FORWARD ARTIFICIAL NEURAL NETWORKS SYSTEM FOR MACHINES TOOLS SELECTION.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 161-169

DOI: 10.5220/0001188101610169

Copyright

c

SciTePress

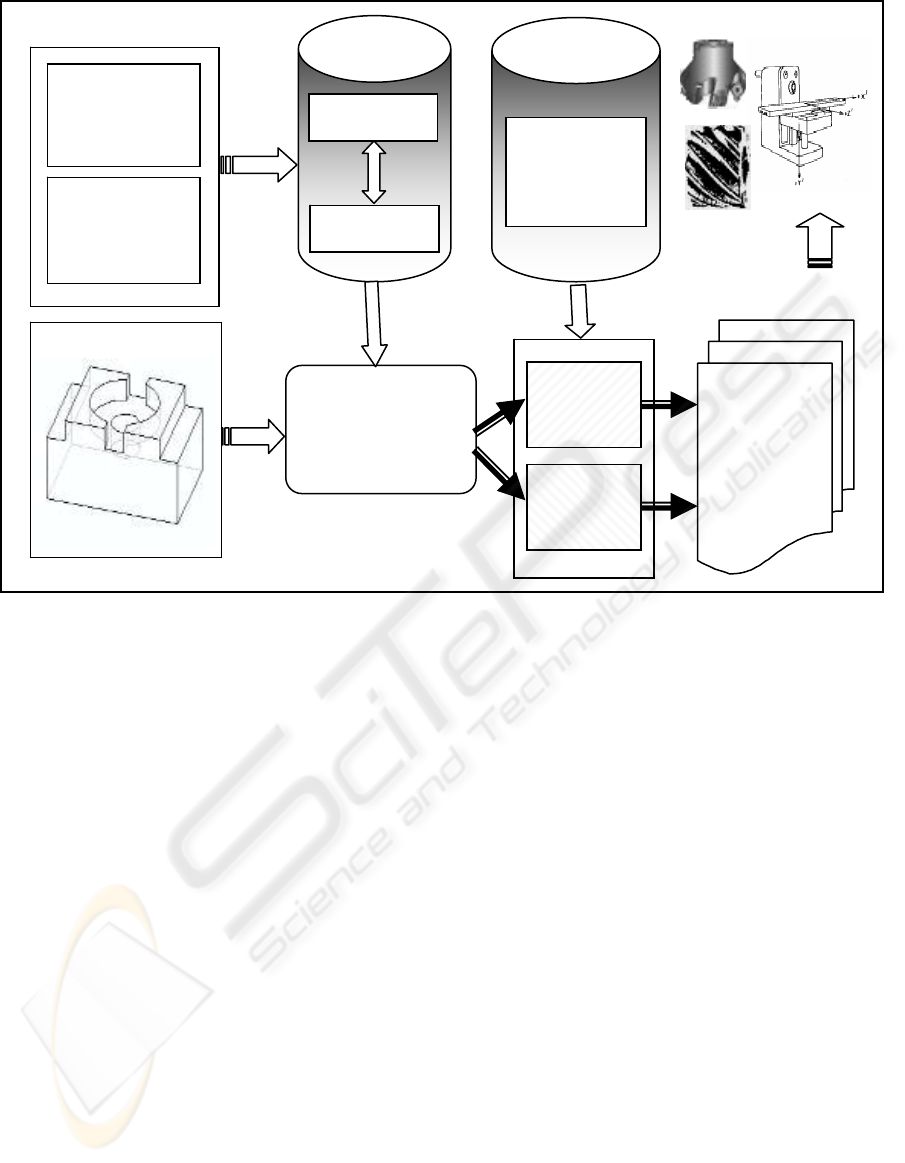

We present in figure 1 the module of the neuronal

system for the selection of the classes of machines-

tools.

2 DEVELOPMENT OF

NEURONAL SYSTEM NN1 FOR

THE CHOICE OF MACHINES

TOOLS

During the development of this module, we have

begun by the creation of database of know-how

starting from an investigation in manufacturing

mechanical companies, with production specialists,

experts, mechanical engineers and skilled workers

production in machining, as well as teachers of

mechanical production.

Indeed, the method used in the expertise of the

production specialists or equivalents is entitled

ETED (Emploi Type Etudié dans sa Dynamique: Job

kind in dynamic study)

(MANDON. N, 1991),

which makes it possible to carry out talks and to

structure the results of the investigations

(W.Eversheim et al., 2001).

There are several manners of classifying the

machines tools, such as: by type of employment, by

architecture (with horizontal spindle, vertical spindle

and directional spindle), by type of order

(conventional, automatic, numerical control... etc),

and by dimensions (displacement following 3 axes

X, Y, Z... etc). In our study we propose a

classification of the machines tools according to the

number of possible axes in a machine tool (one axis,

two axes, three axes, four axes, five axes). This

classification is related to morphologies of

machining features, like their type of machining and

their operations possible (table 1). We show on

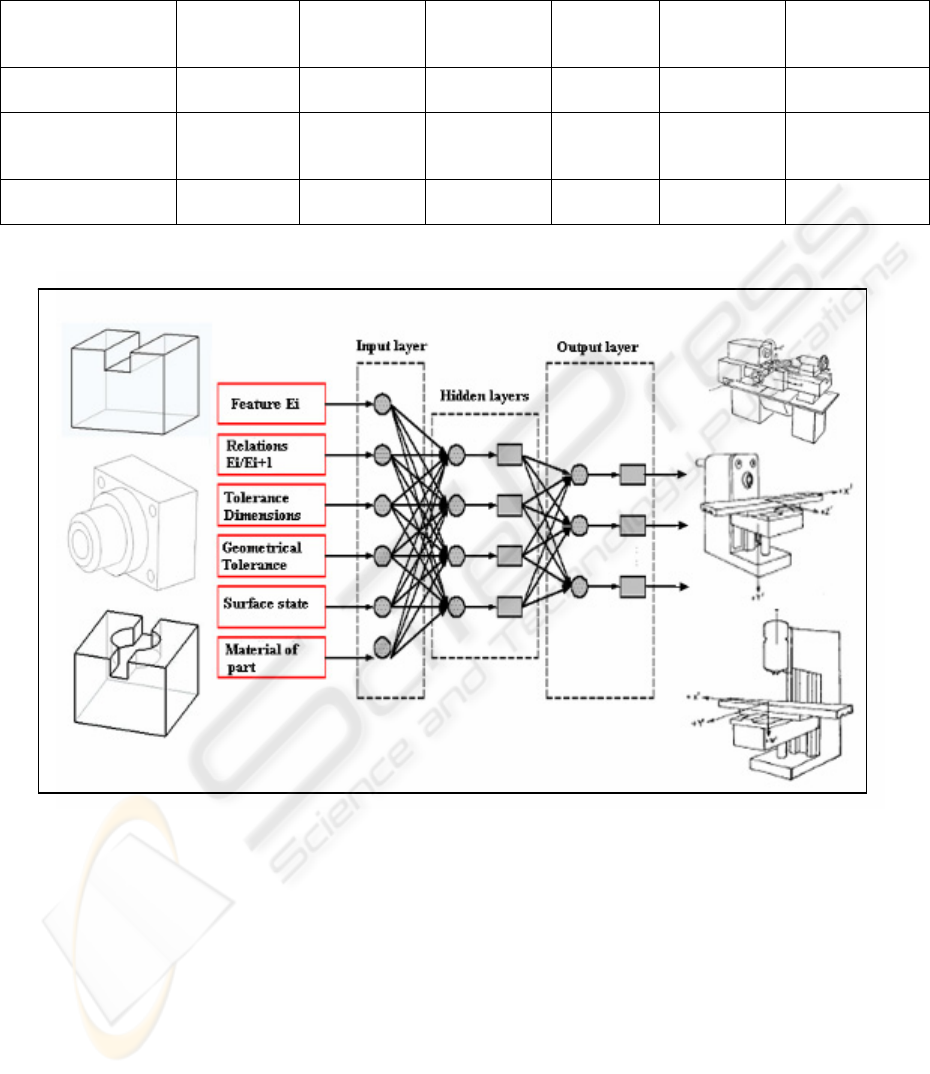

figure 2 the structure of neuronal system NN1 which

is based on the choice of machines tools families in

relation to machining features. The inputs of the

network are the criteria of selection of machine-tools

which are extracted from the basic module of

database of know-how.

Machining

f

eatures

Machines/C

u

t

-tin

g

tools

Database of the

know-how

Workshop of

machining:

- Machines

- Cutting

tools

Resources of

machining available

Classification:

(Families of

machines-tools)

Classification:

(Families of cutting

tools)

Criteria of selection of

machines-tools and cutting

tools in relation to

machining features.

NN1

NN2

Machines

Cutting tools

Machining features

Figure 1: Module of neuronal system for selection of machine-tools and cutting tools

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

162

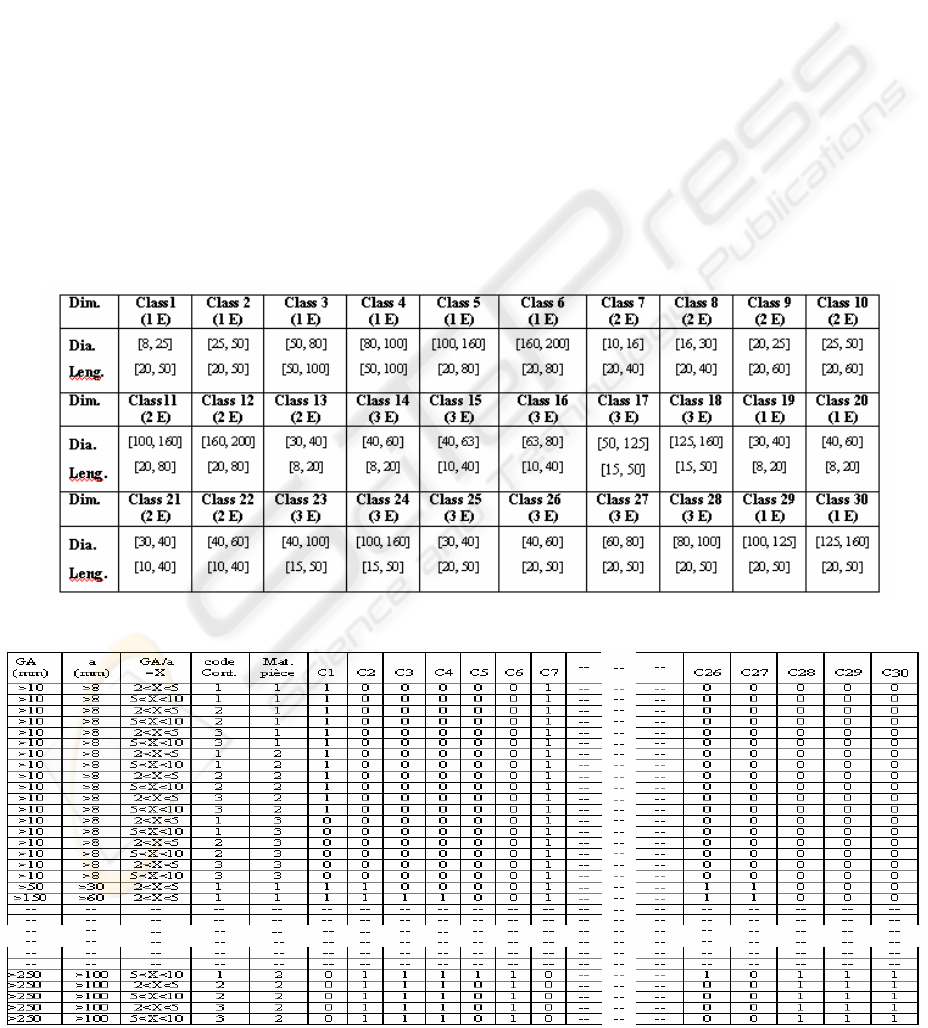

Table 1: Classification of the rotating tools

The necessity of the automatic choice of a

machine-tool in mechanical manufacturing is today

a very interesting stage for the efficiency of a

machining operation as well as the reliability of a

manufacture process planning (G. Chryssolours et

al., 2001) (Chiung Moon et al.,2002)

. Indeed, to

manufacture a machining feature, it exists several

possibilities of machine-tool selection, however to

optimize this choice we must respect certain number

of criteria of the choice of machine-tool (the

morphology of the piece to manufacture,

measurements, the asked precisions, the

dimensional, geometric and technological

constraints,…etc) [5].

The automatic system of the choice of machines-

tools which we used in this study is based on multi-

layer artificial neural networks. They have the

advantage to permit with a certain number of tests to

select the appropriate machine-tool with the

characteristics of proposed machining features

(I.Drstvensek et al., 2000).

The model of multi-layer

neural networks is based on a simple representation

of the biological neurons in form of a function of

several variables. For this sort of networks, the

activity of a neuron is modeled by a real number and

the synapses by coefficients. As their name

indicates it, the multi-layer neural networks are

divided into layers; the first layer is a layer of inputs

Classes of

Machines-Tools

Class 1

(1 axis)

Class 2

(2 axes)

Class 3

(3 axes)

Class 4

(3 axes)

Class 5

(4 axes)

Class 6

(4 axes)

milling

Motions

Z X, Z X, Y, Z X, Z, C X, Y, Z, B X, Y, Z, C

Classes of

Machines-Tools

Class7

(4 axes)

turning

Class 8

(4 axes)

Class 9

(5 axes)

Class 10

(5 axes

Class 11

(5 axes)

Class 12

(5 axes)

Motions X, Y, Z, C 2x(X, Z) 2x(X, Z), C X, Y, Z,

A, C

X, Y, Z, B,

C

X, Y, Z, A, B

Figure 2: Structure of the multi-layer neural networks NN1 for the automatic choice of the machine- tools.

INTEGRATED FEED-FORWARD ARTIFICIAL NEURAL NETWORKS SYSTEM FOR MACHINES TOOLS

SELECTION

163

Table 2: Parameters of the neural networks NN1 for the automatic choice of machines- tools

because it receives the inputs vector, reciprocally the

last layer is a layer of outputs, it produces the

results. The intermediate layers are called hidden

layers, because states of neurons that they contain

are not observable. The proposed neural networks

are a self-adapting structure, it internally modified

until attaining the desired result following the phase

of training and generalization. Indeed, the training

is a development phase of neural networks during

which the behavior of the networks is modified until

ottaining the desired behavior. It is done in the

context of a task or a behavior to be learned.

Information to be treated is coded in the shape of a

inputs vector, which is communicated to the inputs

neural networks (A. Zouidi et al, 2004). The answer

of the network is interpreted starting from the value

of activation of its outputs neurons, of which the

outputs vector. It is a procedure which consists in

estimating the parameters of neural networks, so that

this one as well as possible fills the task which is

affected for him (J. Dunfied et al., 2004).At the end

of this process, the network was to be able to

generate the good solutions for examples which

were not seen before it is the objective of the

generalization phase. This process consists in

generalizing the outputs results of the inputs to

network do not belong to the training base. Indeed,

for the multi-layer neural networks, the training

algorithm used is the retro propagation of gradient

(A. Zouidi et al 2004).The application that we

proposed here for the resolution to machining

problems of prismatic interacting features of the

type groove /pocket

(H.Thomas, 2000).

Indeed, to respect constraints, the geometric

tolerances and the state of surface of workpiece

registered to the definition drawing of machining

feature (Mustafa Yurdakul, 2004), (N. Ahmadi et al.,

2002)

; we affected these features in three different

codes:

(1) without constraint,

(2) dimensional requirements,

(3) geometrical requirements and/or state of

surface.

Besides, we specified the material of

manufacturing workpiece while regrouping

materials in three families according to their

hardness by three different codes :

(1) alloys of copper and alloys of aluminum,

(2) soft steels ,

(3) hard steels and cast irons.

The outputs of the network consists of a matrix

of dimension (5x18), the set of these outputs

describes the proposed solutions by possible

machine-tools classes according to the desired

outputs (S1, S2, S3,…, S11, S12).

For this configuration of the neural networks, we

propose the different types of training according to

number of epochs, estimate of the gradient of errors

and the training function [7]

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

164

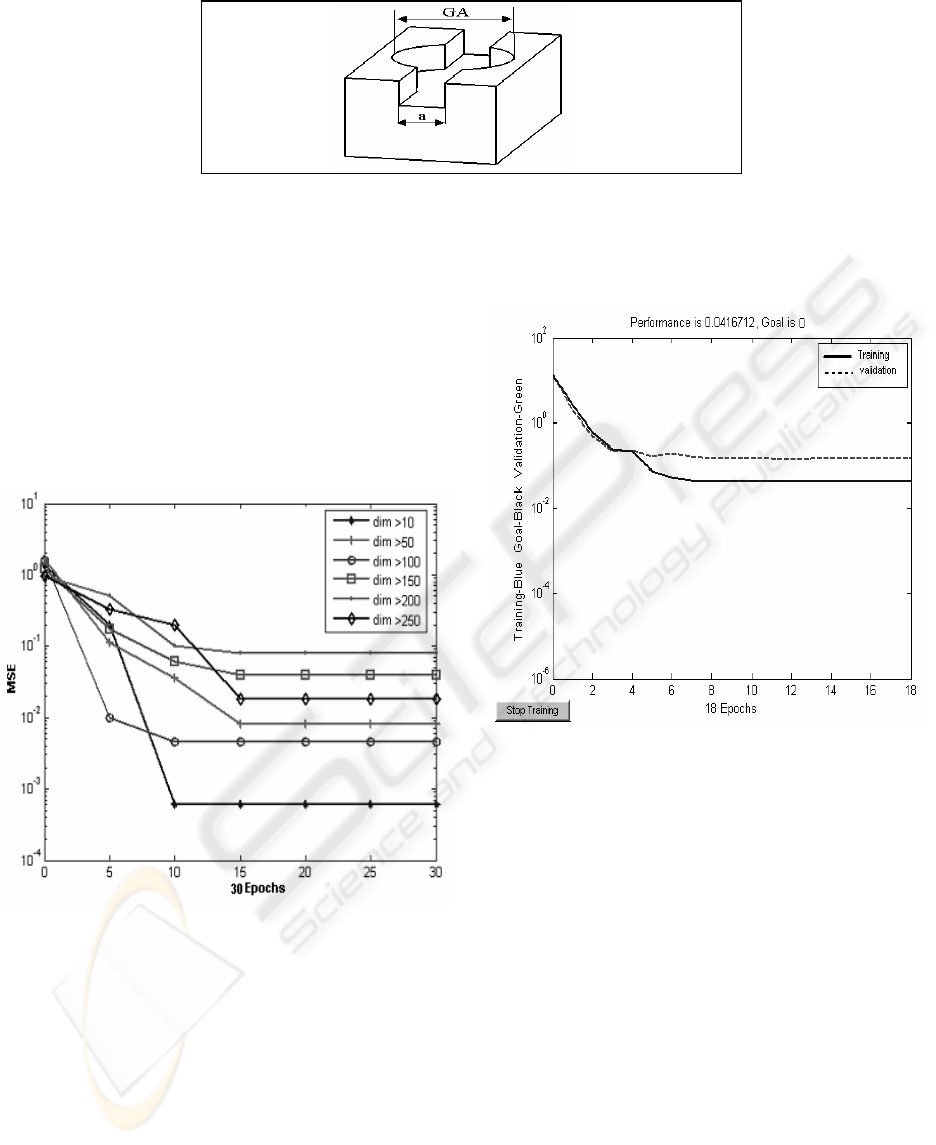

The graphs represented in the figure 4 shows the

evolution of the training mean squared error (TMSE)

according to the number of epochs and

measurements of machining features. Indeed, it is

noticed that the TMSE is weak for the different

measurements of the machining features of our

application and after 18 epochs according to the

proposed measurements, it will have the stability of

the network with a training mean squared error

(TMSE) minimal lower to 0.1.

In order to fix an optimal structure of neural

network, we must choose the parameters of network

well such as the number of the hidden layers, the

number of neurons in the hidden layer and the

function of training and adaptation. Indeed, the best

structure of network is obtained starting from a very

weak TMSE and an optimal number of epochs

"Kopt" so that the generalization mean squared error

(GMSE) is minimal. However, we have presented at

the graphs represented in figure 5 show the neural

networks system an input vector doesn’t belong to

the basis of training then we have examine the

generalization mean squared error and we have

compared it with the one of the training (R. Ben

Khalifa et al., 2003),

(N.BEN Yahia et al, 2000).

Evolution of the error of training (TMSE) and

generalization (GMSE) of our neuronal system for

the automatic choice of machines tools. We notice

that the error of generalization (GMSE) decreases

until a number of epochs (or iterations) to be

determined well, by this value error (GMSE)

increases. This translated it on training of the

network. Indeed, it is obliged to stop the training for

an optimal number of epochs (Kopt=18)

In order to choose the number of optimal neuron,

we made a series of training for the various numbers

of neurons in the hidden layer. The choice of the

optimal number of epochs corresponds to a minimal

GMSE and TMSE.

The number of neurons making it possible to

have a minimal TMSE in this case is 20 neurons.

This phase we enabled to choose the optimal

structure of the network. Lastly, the following

structure was fixed:

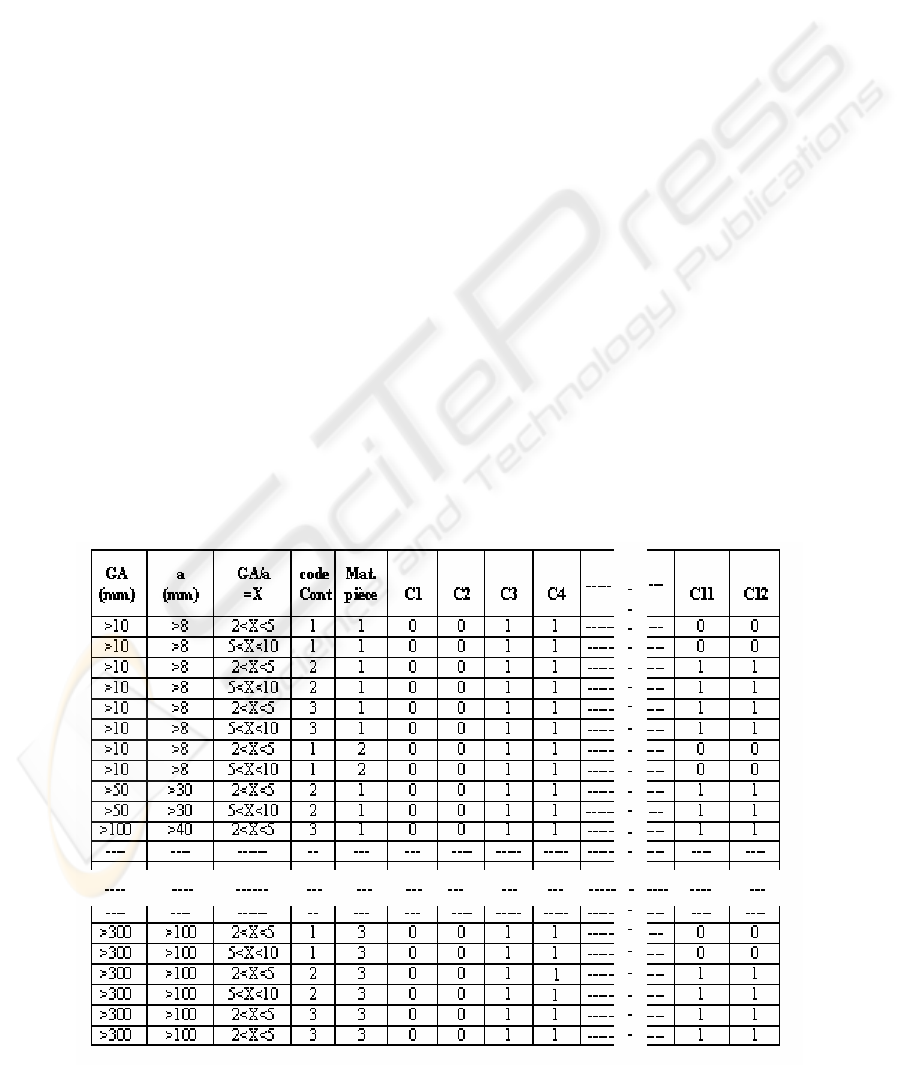

Figure 3: Intersecting features groove / pocket

Figure 4: Result of training of the network NN1.

Figure 5: Evolution of the training error and of

generalization of the NN1

.

INTEGRATED FEED-FORWARD ARTIFICIAL NEURAL NETWORKS SYSTEM FOR MACHINES TOOLS

SELECTION

165

- inputs and outputs: 5 inputs and 12 outputs,

- number of hidden layers: 1 only hidden layer,

- number of neurons in the hidden layer: 20

neurons,

- activation function : hyperbolic tangent for the

set of the neurons in the network.

3 DEVELOPMENT OF

NEURONAL SYSTEM NN2 FOR

THE CHOICE OF CUTTING

TOOLS

The structure of the automated choice system for

cutting tools that we used is based on the multi-layer

neural networks. They have the advantage of

making it possible with a certain number of tests to

model the machining process to prismatic features

by the proposal of the cutting tools.

The application that we have proposed here for

the automatic choice of cutting tools by neural

networks is the same that the one for automatic

choice of machine-tools, the feature studied consists

of prismatic interacting features of type groove /

pocket (figure 3).

The study of various solutions of choice of

cutting tools proposed by expert production

specialist (or equivalent) which will be coded with

the nodes of inputs of networks. Indeed, the inputs

of the system are coded and organized in a matrix

whose columns are a interval of dimensions (GA, a),

studied types of constraints and material of features,

as well as desired exits are tools classes (c1, c2,

c3..., c30). Table 4 shows the parameters of neural

networks for the 30 classes which are shared in

relation to interval of cutting tools dimensions

(diameter and length) (table3).

Table 3: Classification of the rotatin

g

tools.

Table 4: Parameters of the neural networks NN2 for the automatic choice of cutting tools

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

166

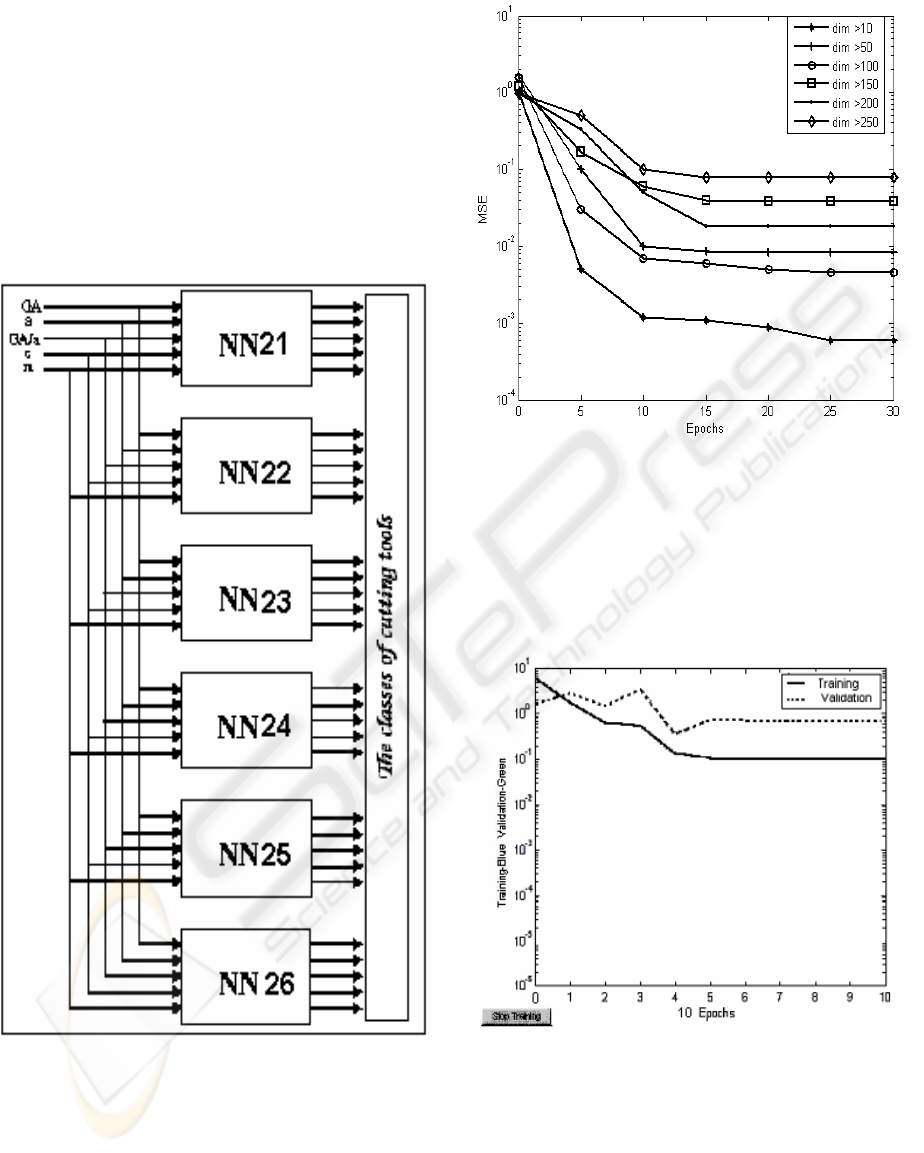

The best solutions of the choice of cutting tools

classes for an effective system are obtained by

separated 6 networks (NN21, NN22, NN23, NN24,

NN25, NN26) (figure 6), every network to a matrix

of input and a matrix of output in the same way

dimension (5x18) (table 4). Outputs of every

network also constitute a matrix of dimension

(5x18), the whole of these outputs describes

solutions proposed by the possible cutting tools

classes according to desired outputs (S1, S2, S3, S4,

S5…, S29, S30) (R. Ben Khalifa et al., 2003).

We have studied the evolution of training error

only for the network NN21 since the different results

that we have found for other networks are nearly

very near. The figure 7 shows the evolution of the

training mean squared error TMSE according to

number of epochs and measurements of machining

features for neural networks NN21.

Besides, it is noticed that the TMSE is weak for

the different measurements of the machining

features of our application and after 10 epochs

according to the proposed measurements, it will

have the stability of the network with a training

mean squared error (TMSE) minimal lower to 0.1.

The graphs represented in figure 8 show the

evolution of the error of training (TMSE) and

generalization (GMSE) of our neuronal system for

automatic choice of cutting tools.

The optimal

number of epochs in this case is k

op

=10 epochs.

Figure 6: Global architecture of neural system NN2

Figure 7: Result of training of the network NN21

Figure 8: Evolution of the training error and of

generalization of the NN21

INTEGRATED FEED-FORWARD ARTIFICIAL NEURAL NETWORKS SYSTEM FOR MACHINES TOOLS

SELECTION

167

This phase has permitted us to choose the

structure of the optimal network.

Finally, the following structure was fixed:

- inputs and outputs: 5 inputs and 5 outputs,

- number of hidden layers: 3 hidden layers

- number of neurons in the hidden layer: 30

neurons,

- activation functions: hyperbolic tangent for the

whole of neurons in the network.

In this application, we have defined a network of

neurons that permits a choice efficient of cutting tool

classes, a generalization sequence different training

sequence permitted to specify performances of the

neural networks. Several trainings permitted to fix

the optimal structure of the network, permitting it to

have a maximal generalization capacity (minimal

GMSE). (R. BenKhalifa et al., 2005).

4 DEVELOPMENT OF THE

INTERFACE OF NEURONAL

STSTEM

In order to model this kind of application, we must

create an interfacing-user under CAD/CAM

software that allows the process planners to

communicate with these applications of a simple and

fast manner. We have created a user-interface with

Visual Basic language under CAD system software,

as well as we have created an interfacing or

compilation between MATLAB and VBA under

CAD system.

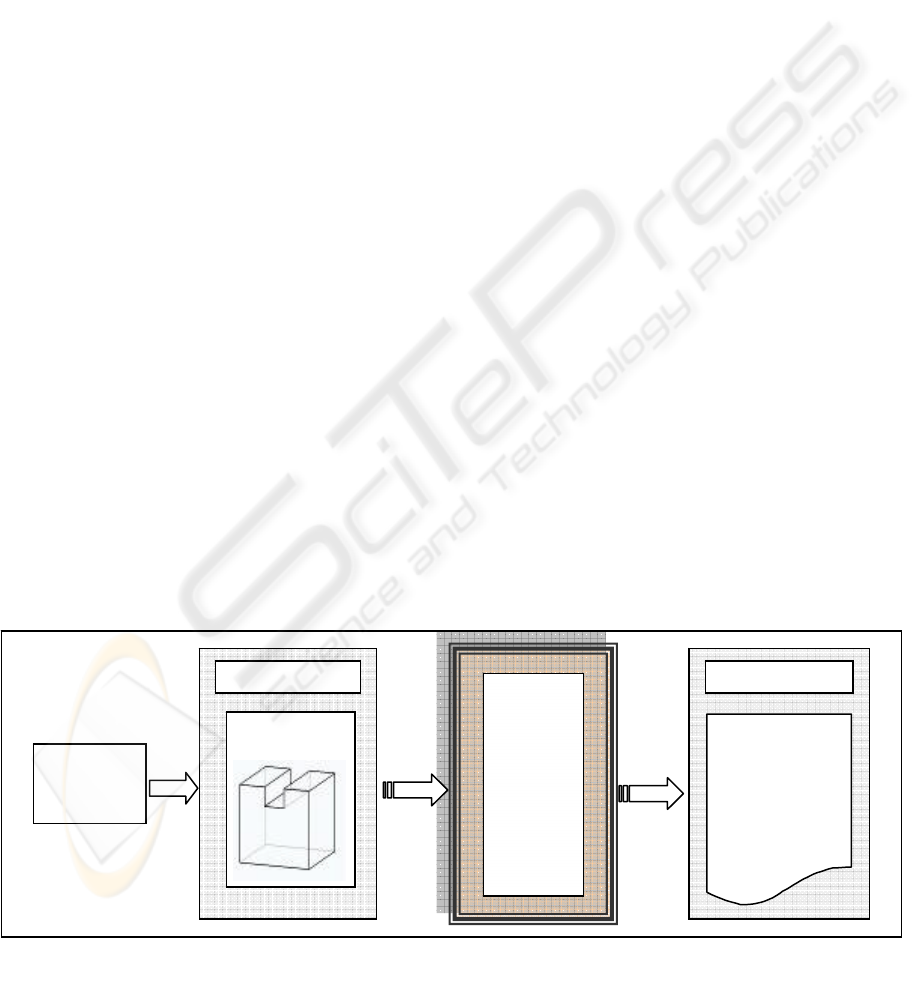

We show in figure 9 the module of neuronal

system interface with CAD/CAM systems. This

module was to realize with Visual Basic language,

it makes possible to facilitate the communication

and use of neuronal system for automatic choice of

machines and the cutting tools ( Mustafa Yurdakul,

2004).

5 CONCLUSION

From the expertise in process planning, we have

succeeded in structuring several technological data

under shape of arrays (matrixes) that are going to

have entered directly in the structure of the network

under Matlab by his Tool-box

(N.BEN Yahia, 2002).

The validation has been proposed here for the

relative cutting tools choice to interaction machining

features of type groove / pocket.

The approach neuronal remains promising in

relation to approaches of by variants, especially in

the speed of implantation and appropriate up to date

in industry manufacturing, as well as the precision in

the automatic choice of machines-tools of the data

base. The proposed system permits as the

verification of consistency machine-tools/machining

features.

Demand

product

CAD S

y

stem

Module of the neuronal

System

CAM S

y

stem

Program NC

%100

N10………….

N20………….

Figure 9: Module of the interface of neuronal system

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

168

REFERENCES

A. Zouidi, A. Chaari M. Stambouli and F. Fnaiech «

Nonlinear Continuous Time Modeling of a High

Pressure Mercury Vapor Discharge Lamp Using Feed

ForwardBack-propagation Neural Networks » IEEE

icit 2004 Yasmine-Hammamet, December 8-10, 2004.

C.Gologlu « Machine capability and fixturing constraints-

imposed automatic machining set-ups generation »

Journal of Materials Processing Technology 148

(2004) 83–92.

Chiung Moon , Moonhwan Lee, Yoonho Seo, Young Hae

Lee « Integrated machine tool selection and operation

sequencing with capacity and precedence constraints

using genetic algorithm », International Journal of

Computers & Industrial Engineering 43 (2002) 605–

621.

G.Chryssolours, S.Zannis, C.Derdas, K.Tsirbas, «

Dimensional Accuracy of FDM Parts » The 34

th

CIRP

International Seminar on Manufacturing Systems, 16-

18 May 2001, Athenes, Greece.

H.Thomas, « Génération de séquences d’alésage par

approche neuronal », IDMME 2000, 3rd International

Conference on Integrated Design and Manufacturing

for Mechanical Engineering, Canadian Society for

Mechanical Engineering.

I.Drstvensek et M. Brezocnik « On intelligent CAD/CAPP

Integration Base on Feature Recognition and

Evolutionary Computation », IDMME 2000, 3

rd

International Conference on Integrated Design and

Engineering, Canadian Society for Mechanical

Engineering 2000.

J. Dunfied, M. Tarbouchi and G. Labonte « Neural

Network Based control of a Four Rotor Helicopter »

IEEE icit 2004 Yasmine-Hammamet, December 8-10,

2004.

L. Ding1, Y .Yue Novel « ANN-based feature recognition

incorporating design by features », International

Journal of Computers in Industry xxx (2004) xxx–xxx.

MANDON N, L’emploi-type étudié dans sa dynamique,

CEREQ, Collection Documents, 1991.

Mustafa Yurdakul, « AHP as a strategic decision-making

tool to justify machine tool selection », Journal of

Materials Processing Technology 146 (2004) 365–

376.

N.BEN Yahia, F. Fnaiech, B.Hadj Sassi, « Application des

réseaux de neurones multicouche pour

l’élaboration de phase d’usinage », Conférence

International Francphonie d’Automatique CIFA, pp 640

645, 5-7 Juillet, 2000.

N.BEN Yahia et B.Hadj Sassi, « Elaboration automatique

de phases d’usinage basé sur les réseau de neurones

artificielles » Conférence International de Productique

( CPI 99) 25-26 Nov. 1999 au Maroc (FST de Tanger).

N.BEN Yahia. Processus d’élaboration de gamme

automatique d’usinage : application aux entités

prismatiques Thèse de doctorat, ENIT, 2002.

N. Ahmad and A.F.M. A.Haque « Artificial Neural

Networks Based process selection for cylindrical

surface machining », Proceedings of the Int. Conf. on

Manufacturing, ICM 2002 09-11 August, 2002,

Dhaka. pp.321 – 326.

R. BEN Khalifa, N. BEN Yahia, A. Zghal, « Elaboration

d’un système neuronal pour le choix automatique des

outils tournants », Journées Scientifiques et

Pédagogiques de Mécanique et Energétique JSPME

ISET Gafsa, 1, 2, 3 Décembre 2003 p101-107.

R. BEN Khalifa, N. BEN Yahia, A. Zghal, « Choix

automatique des machines-outils basé sur les réseaux

de neurones multicouches », Premier Congrès

International Conception et Modélisation des

Systèmes Mécaniques, CMSM’2005 23-25 Mars

s2005, Hammamet Tunisie.

BEN Khalifa, N. BEN Yahia, A. Zghal, «Automated

selection of machines-tools using artificial neural

networks », 2nd AUS International Symposium on

Mechatronics, AUS-ISM05, April 19–21, 2005,

American University of Sharjah Sharjah, United Arab

Emirates.

R. BEN Khalifa, N. BEN Yahia, A. Zghal, «Intégration

des réseaux de neurones multicouches pour le choix

automatique des machines-outils », 6

e

Congrès

international de génie industriel – 7-10 juin 2005

Besançon, France.

W.Eversheim, M.Koschig, N.Michalas, « Knowledge-

based Technology Data Management » The 34

th

CIRP

International Seminar on Manufacturing Systems, 16-

18 May 2001, Athenes, Greece.

INTEGRATED FEED-FORWARD ARTIFICIAL NEURAL NETWORKS SYSTEM FOR MACHINES TOOLS

SELECTION

169