TOPOLOGICALLY ROBUST RECONSTRUCTION OF A 3D

OBJECT WITH ORGANIZED MESHING

Junta Doi, Wataru Sato

Department of Computer Science, Chiba Institute of Technology, Narashino, Japan

Keywords: 3D reconstruction, Polygonal scanning, Organized meshing, Quadrilateral mesh, Hexagonal mesh, Matrix

format data structure, 3D shape modification, Topology conserved reconstruction.

Abstract: This paper proposes a practical, topologically robust and ranging error resistive shape modeling procedure

that approximates a real 3D object with the matrix-formatted organized meshing for the 3D shape processing.

A geometric model with desired meshing, not limited to triangular one, but also quadrilateral, hexagonal or

n-gonal mesh, is directly reconstructed based on a solid modeling approach. The radial distance of each scanning

point from the axis of the cylindrical coordinates is measured by laser triangulation. The angular and vertical

positions of the laser beam are two other coordinate values of the scanning. A face array listing (topology),

which defines the vertex (sampling point) connectivity and the shape of the mesh, is assigned to meet the

desired meshing. Stable meshing, and hence, an accurate approximation, free from the shape ambiguity

unavoidable in the widely used ICP (Iterative Closest Point) modeling, is then accomplished. This proposal

allows a practical and versatile reconstruction and the successive 3D shape modification.

1 INTRODUCTION

The problem of shape reconstruction has been the

focus of research across many fields because of its

wide applications. Attempts to measure the shape of

objects and to construct geometric models have a

long history. There are a great number of books

(Mantyla, 1988, Hartley et al., 2000, and Forsyth et

al., 2003), review articles (Chen et al., 2000, Scott et

al., 2003, and Blais, 2004), papers (Besel, 1992, Turk

et al., 1994, Levoy et al., 2000, Rusinkiewicz et al.,

2001, Godin et al., 2002, Pauly et al., 2003, and Dey

et al., 2004), and products (Simple3D, 2005) dealing

with the problems.

This study is to provide technology that would

reconstruct the objects, such as, cultural heritage

artifacts and reliefs, accurately and precisely as they

are in a usually noisy environment. A 3D shape

processing for reuse of the geometric models is our

purpose of the proposal.

Surface models with unorganized triangular

meshes have been built based on the ICP algorithm

from the scanned cloud points obtained by, for

instance, triangulation scanners so far. A great deal of

research efforts has been made on the problem. The

ICP algorithm is widely used and well proven in

some applications; however, it is ranging-noise

sensitive and hence shape-ambiguous, and compli-

cated for constructing a fully automated system.

In general, the presence of noise (the ranging

noise or triangulation error) is typical for the

scanning process. Retrieving surface topology from

surface geometry as the algorithm is not easy, when

the ranging noise is unavoidable. Many attempts have

been made to overcome the problem; however, there

is no known algorithm that has theoretical guarantees,

without assumptions, for surface reconstruction in the

presence of noise (Dey et al., 2004).

The triangulation error arises mostly from the

oblique reflection of the incident laser beam on the

local surface. To reduce the error, a large object

model with rather flat surfaces is to be employed. The

surface polishing is most effective for an error-free

and reliable triangulation. These measures are,

however, not applicable to most of the objects that

should be treated as they are.

Contrary to the widely used procedures, this

paper proposes an approach such that the surface

topology is first assigned and a geometric model with

a solid model format with the desired meshing is

directly generated.

In other words, the method involves a proto-

typical model (e.g., the unit cylinder in Fig. 1) being

first prepared by considering the shape of the object

154

Doi J. and Sato W. (2005).

TOPOLOGICALLY ROBUST RECONSTRUCTION OF A 3D OBJECT WITH ORGANIZED MESHING.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 154-159

DOI: 10.5220/0001179001540159

Copyright

c

SciTePress

and then modifying every mesh point to reflect the

geometric shape of the object. This is “topology is

first and then geometry” not that “geometry first and

then topology” as the IPC modeling.

This model is called “B-reps (Boundary repre-

sentations)” which describes a 3D object as a set of

surfaces that separate the object interior from the

environment and is a polygon mesh approximation of

a curved object surface.

Usually, irregular triangular meshes, generated,

for instance, by the algorithm, are re-sampled into

regular meshes when required. However, point-

locatable nature and accuracy are lost in the

re-meshing process. Very many scientific efforts are

focused on the unorganized meshing, however, to our

knowledge; few published works that can be related

to this proposal of organized meshing have been

presented.

During morphing or warping, which is a funda-

mental operation in computer graphics, the initially

constructed model is deformed into another model.

Usually it is computer-graphics-based and operation

is applied to unorganized triangular meshes, which

are not surface-point-position- locatable.

O

O

u

u

r

r

s

s

h

h

a

a

p

p

e

e

d

d

e

e

f

f

o

o

r

r

m

m

a

a

t

t

i

i

o

o

n

n

i

i

s

s

a

a

p

p

p

p

l

l

i

i

e

e

d

d

t

t

o

o

t

t

h

h

e

e

o

o

r

r

g

g

a

a

n

n

i

i

z

z

e

e

d

d

a

a

n

n

d

d

p

p

o

o

i

i

n

n

t

t

-

-

l

l

o

o

c

c

a

a

t

t

a

a

b

b

l

l

e

e

m

m

o

o

d

d

e

e

l

l

,

,

o

o

r

r

i

i

g

g

i

i

n

n

a

a

t

t

e

e

d

d

f

f

r

r

o

o

m

m

t

t

h

h

e

e

m

m

o

o

d

d

e

e

l

l

i

i

n

n

g

g

p

p

r

r

o

o

c

c

e

e

d

d

u

u

r

r

e

e

,

,

u

u

s

s

i

i

n

n

g

g

i

i

n

n

t

t

u

u

i

i

t

t

i

i

v

v

e

e

m

m

a

a

t

t

r

r

i

i

x

x

-

-

t

t

y

y

p

p

e

e

o

o

p

p

e

e

r

r

a

a

t

t

o

o

r

r

s

s

e

e

n

n

a

a

b

b

l

l

i

i

n

n

g

g

t

t

h

h

e

e

q

q

u

u

a

a

n

n

t

t

i

i

t

t

a

a

t

t

i

i

v

v

e

e

s

s

h

h

a

a

p

p

e

e

m

m

o

o

d

d

i

i

f

f

i

i

c

c

a

a

t

t

i

i

o

o

n

n

,

,

e

e

v

v

a

a

l

l

u

u

a

a

t

t

i

i

o

o

n

n

a

a

n

n

d

d

C

C

A

A

D

D

c

c

o

o

m

m

p

p

a

a

t

t

i

i

b

b

i

i

l

l

i

i

t

t

i

i

e

e

s

s

.

.

Laser triangulation sensors using the spot and

stripe projections are used for the examples in this

paper, but the measurement procedure is general and

not limited to these. As a modeling/rendering system,

we prepared some solid model interfaces for popular

computer graphics or computer-aided design

systems.

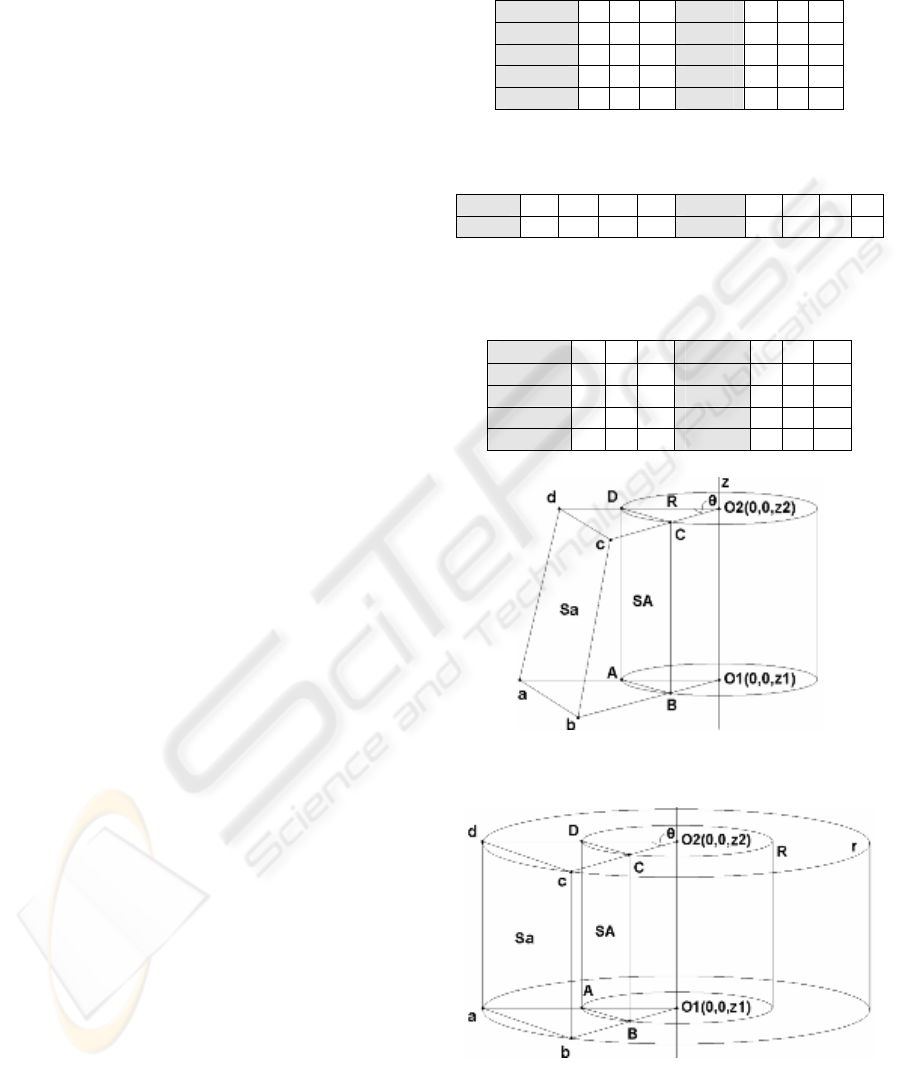

2 SOLID MODELING

In the illustration of a solid model data structure in

Fig. 1, a pentahedral volume element, in which the

peripheral surface is covered with a rectangular mesh,

small enough to approximate the curved object

surface, is to be measured to approximate the object

shape. A quadrilateral mesh Sa, consisting of four

surface points, a, b, c and d, is one of the sampling

points on the object surface. Points A, B, C and D are

mesh points consisting of a rectangular mesh SA on

the unit cylinder surface. The rectangu- lar mesh SA

is a perspective projection of the quadrilateral mesh Sa

to the unit cylinder surface, and vice versa. Each radial

distance of the object surface point from the axis of

rotation (z-axis), for instance, “r

a

, r

b

, ···” is

sequentially measured. We call this type

Table 1: Vertex array listings (geometry) for the rectan-

gular surface mesh SA (left, on the unit cylinder surface)

and the quadrilateral Sa (right, on the object surface) in Fig. 1.

Vertex r θ z Vertex r θ z

SA: A

1 0 z

1

Sa: a

r

a

0 z

1

B

1 θ z

1

b

r

b

θ z

1

C

1 θ z

2

c

r

c

θ z

2

D

1 0 z

2

d r

d

0 z

2

Table 2: Face array listings (topology) for the mesh SA (on

the unit cylinder) and Sa (on the object surface) in Fig.1.

Table 3: Vertex array listings (geometry) for the quadri-

lateral mesh SA (left, on the object surface) and the rectan-

gular mesh Sa (right, on the unit cylinder surface) in Fig. 2.

Vertex

r θ z

Vertex

r θ z

SA: A r

a

0 z

1

Sa: a 1 0 z

1

B r

b

θ z

1

b 1 θ z

1

C r

c

θ z

2

c 1 θ z

2

D r

d

0 z

2

d 1 0 z

2

Figure 1: The mesh structure of a solid model cylinder for

scanning of an object on the axis (object-modeling mode).

Figure 2: The mesh structure of a solid model concentric

cylinder for the outer scene scanning (scene-modeling mode).

The outer cylinder with a radius “r” is a cut-off limit of the

ranging sensor. A quadrilateral mesh “SA” is on the object

surface. “Sa” is a rectangular mesh on the cut-off cylinder.

Face 1 2 3 4 Face 1 2 3 4

SA(u) B C D A Sa(o) b c d a

TOPOLOGICALLY ROBUST RECONSTRUCTION OF A 3D OBJECT WITH ORGANIZED MESHING

155

of modeling the “object-modeling mode.”

A vertex array listing, which is called “geometry”

and represents the geometric coordinate values in 3D

space is shown in Table 1. The face (mesh) array

listings for the Sa and SA are shown in Table 2.

Other four comprising surfaces of the wedge shaped

pentahedral volume element are similarly defined

(Tables not shown). The listing is called “topology”

and defines the shape of the face (number of vertices

or edges) and also defines the listing sequence of the

vertices or connectivity. The listing sequence of the

vertices in the face list defines the normal vector

direction of the face and determines on which side of

the face the solid part of the object exists. This mesh

is directly compatible with that used in the BEM

(Boundary Element Method).

As shown in Fig. 1 and Table 2, the variation in

the radial distance (depth) of a, in principle, has no

effect on the connectivity array of the face, if point a

locates along the radial line segment O1-a or O1-A.

This relation is also valid for the other points b, c,

and d as well. Therefore, the connectivity array of the

mesh is conserved if the four points similarly locate

along each radial line. The vertex connectivity of Sa

is the same as that on the unit cylinder, SA as shown

in Fig. 1 and Table 2. This means that the face array

listing assigned for the unit surface SA is valid for the

object surface Sa. N-gonal meshes are similarly

constructed (Doi et al., 2004).

When the triangulation sensor is set at the axis of

the coordinate and rotates to measure the distance to

the outside scene, the solid modeling is as shown in

Table 3 and Fig. 2, where the object surface is SA and

the mesh is defined on a cut-off circle or a unit circle.

A Boolean subtraction of a pentahedron including SA

from that including Sa results in a hexahedral

element in a solid model of the scene. We call this the

“scene-modeling mode.” The modeling procedure is

similar to the “object- modeling mode.”

Our mesh shape is arbitrary. In this procedure, it

is triangular, quadrilateral, hexagonal or even n-gonal,

if required for a more reduced number of meshes.

Figure 3 shows a hexagonal mesh. Our hexagonal

meshing is based on a 1/2 interlacing scan as shown

in the figure, similar to that of the NTSC video format.

A hexagon can be broken down into six small

triangular meshes, one is, for instance ABG, or two

trapezoids, for instance, ABCF, or three rhomboidal

meshes, for instance, GDEF. The combination of

hexagonal, rhomboidal and triangular meshes is

useful to efficiently cover the variously curved object

surfaces with a reduced number of meshes.

Our data format is a raster scan type or a matrix

format according to the above procedure as described

Figure 3: An example of a hexagonal mesh ABCDEF, which

is consisted of two trapezoidal ABCF and DEFC, three rhom-

boids, such as, BCDG, and six triangles, such as, ABG.

Three horizontal scan lines, (L-1), (L) and (L+1) make a

hexagonal mesh. A sequential scan makes a rectangular mesh.

Figure 4: Photograph of the object sculpture head (Niobe)

(top) and the shaded image of the object-modeled result

(bottom). Angular scanning step is 0.4 degrees in the frontal

region (rear; 0.8 degrees)and vertical step is 0.45 mm

Figure 5: Photograph of the object sculpture shown above

(left) and the shaded image of the modeled result (right).

Figure 6: Shaded images of the modeled nose part of the

sculpture (Niobe). Modeled result with overlaid

quadrilateral meshes (left) and hexagonal meshes (right).

ICINCO 2005 - ROBOTICS AND AUTOMATION

156

above and it is as follows.

r = [r

ij

] =

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

nmn2n1

2m2221

1m1211

rrr

rrr

rrr

"

#%##

"

"

(1)

An element r

ij

represents the radial distance of a

sampled surface point at the angular position “j” and

at the vertical position “i” in the scanning This matrix

can easily locate an arbitrary point on the object only

by specifying “i” and “j.”

An object such as a sculpture is placed on a turn-

table which is driven by a geared pulse motor with

angular resolution of 0.02 degrees. This means that

the horizontal resolution is 0.015 mm at the radius of

43 mm and there are a maximum of 18,000 horizontal

meshes in one 360 degree turn. The translational

resolution of the vertical slider, which is also driven

by a geared pulse motor, is 0.015 mm with a

maximum stroke of 500 mm. There are 33,333

vertical meshes at maximum in the full stroke.

Therefore, the maximum number of the quadrilateral

meshes is 600 million. In our 600 mega-cloud-points,

each mesh contains additional RGB color

information.

In the demonstrations hereafter, however,

rendering points are reduced to 1/10 in horizontal,

1/10 in vertical and 1/100 of the scanned points in

total, which is about 6 mega-points, for a file size

reduction and quick rendering.

A triangulation sensor with a 690-nm diode laser

was installed on the vertical slider. The laser power is

15 mW and the spot size on the object surface is about

0.3 mm in diameter. A sensing range from 250 mm to

750 mm is produced here with a resolution of 0.01

mm at best. A laser stripe projector with a line width

of 1 mm was also used. In the proposal, the

measurement procedure is general and not limited to

this type of sensing. As a modeling/rendering system,

we prepared solid model interfaces for the popular

3D computer graphics and computer-aided design

systems.

3 RESULTS AND DISCUSSION

The desired meshing, for instance, the rectangular

mesh SA is first assigned for the sampling point

connection and then the vertex array listing is

continuously updated. Our procedure results in the

“B-reps” model, which describes a 3D object as a set

of the organized meshes.

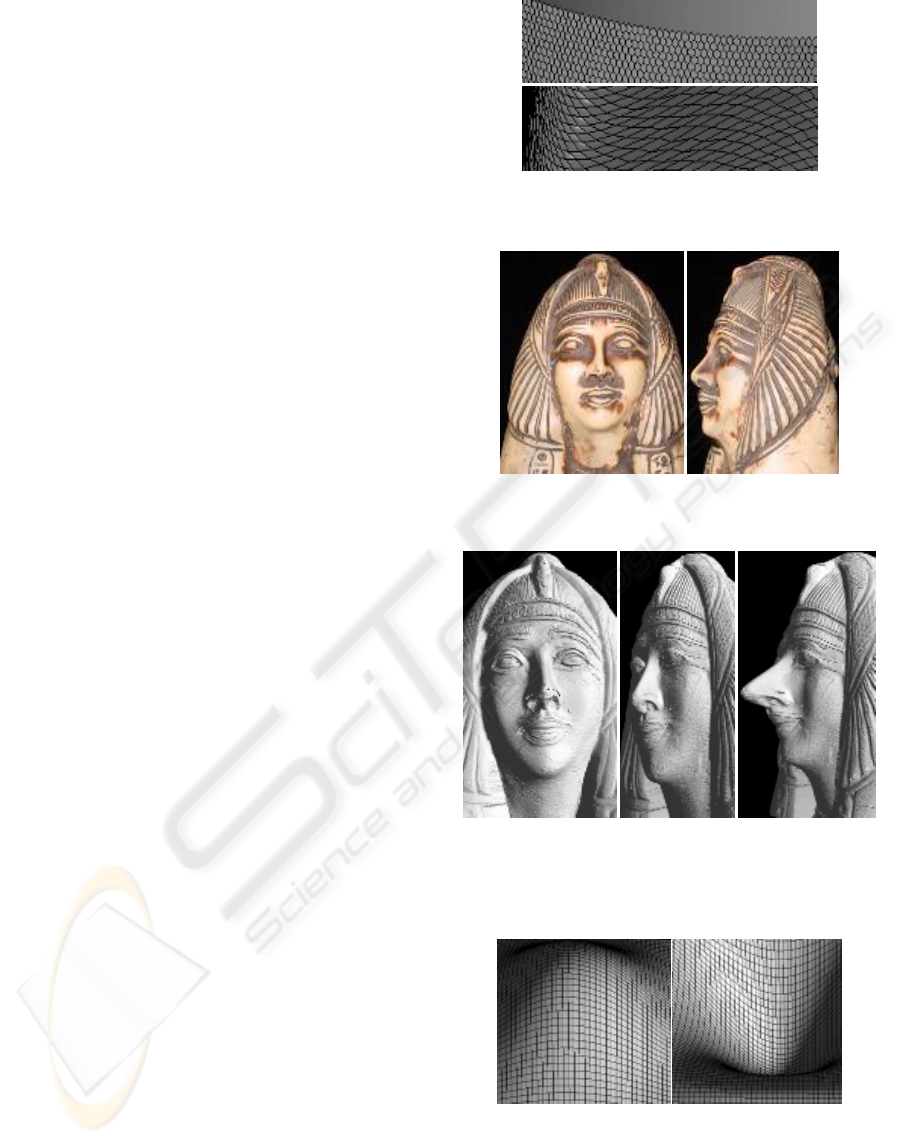

Photographs of a plaster sculpture (Niobe) are in

Figs. 4 (top) and 5 (left). The object-modeled result is

shown in Figs. 4 (bottom) and 5 (right). The result is

estimated to be accurate in an extent of the resolution

Figure 7: Hexagonal meshes on the unit cylinder in Fig. 2

(top) and rhomboidal meshes made from the hexagons.

Figure 8: Photographs of an object stone sculpture (Cleopatra).

The face is 60 mm high and partly black painted.

Figure 9. Shaded images of the modeled results. A frontal

image (left) and a side image (center), a side image of the

shape modified long nose (right). A 20% of the radial

distance from the axis around the top of the nose is expanded.

Figure 10: Two examples of 128x128 (overlaid wire-frame

representation in 64x64) shape-to-shape (depth-to-depth)

transformation operators. The left figure is positive and the

right negative. The parameter distribution is sinusoidal in

horizontal (peripheral) and vertical directions. They are

configured similarly to the 2D image processing operators.

TOPOLOGICALLY ROBUST RECONSTRUCTION OF A 3D OBJECT WITH ORGANIZED MESHING

157

of 0.015 mm. in all three directions.

Figure 6 (left) is an example of the modeled result

with quadrilateral mesh. Here, triangulation is based

on the laser light stripe projection. It is not as accurate

as the laser spot triangulation. An example of the

modeled result with hexagonal meshes is shown in

Fig 6 (right). An example of the hexagonal meshes on

the unit cylinder is illustrated in Fig. 7 (top) and an

example of the rhomboidal meshes from the

hexagonal meshes is in Fig. 7 (bottom).

Photographs of a stone sculpture (Cleopatra) are

shown in Fig. 8. Some ranging noises are observed in

the modeled result (Data not shown). In spite of the

noises, the surrounding mesh points are observed as

unaffected, showing that each noise is standing alone

and isolated, and the topology is robust and

unchanged as expected from the modeling procedure

explained previously. The smoothed model is shown

in Figs. 9 (left) and 9 (center).

A 3x3 or 5x5 depth-to-depth transformation

operator, which is similar to a two-dimensional

smoothing operator, is sequentially applied to the

matrix-type output data. If the noise is detected, the

point is replaced with the surrounding data.

The matrix type data is convenient and essential

for modifying a local shape when locating the target

position. In Fig. 8 (right), the nose of the statue is

modified in shape and size. Referring to the initial

model in Fig. 8 (center), the modifications are

three-dimensionally applied and evaluated. This is

supposing the restoration of a broken artifact, for

instance, the addition of a lost nose, or for virtual

training of, for instance, cosmetic surgery. In the

figure, a 128x128 depth-to-depth transformation

operator, shown in Fig. 10 (left), similar to the image

intensifying operator, is applied.

The modeled result may be used again as an

operator. Two examples are shown in Fig. 11. One is a

rectangular matrix in the cylindrical surface and the

other is a recursive operator generated by this

modeling procedure for use in convolution or 3D

shape fusion. This is not the so called morphing

operation but the quantitative 3D shape operation

with CAD compatibility.

A combination of variously shaped polygons is

used for efficient meshing and watermarking as

shown in Fig. 12. Figure 13 (left) is a photograph of

the backside of a scarab beetle stone and the modeled

result (right). It is about 100 mm long and 70 mm

wide. An underside image of the stone engraved with

hieroglyphs is shown in Fig. 14 (left) and the shaded

image of the modeled result is in Fig 14 (right). It is

an example of the scene-modeling mode. The

modeling is similar to a reconstruction of a relief. In

the comparison, a pictorial image is not the same as

the modeled depth image. It may be concluded that

the depth image is well reproduced in an extent of

Figure 11: A bread arc-board instead of a planar board, such

as Eq. (1) (left), and a customized 3D depth-to-depth

transformation operator, which may be a thus reconstructed

model of a real object based on triangulation. This 3D

shape replaces a part of the initial shape. Convolution of the

reconstructed model operator fuses two shapes together.

Figure 12: An example of polygonal surface comprising of

hexagonal, trapezoidal, rhomboidal and triangular meshes.

A combination of the variously shaped polygons serves the

efficient surface approximation with a reduced number of

meshes and also embedded watermarking.

Figure 13: Backside photograph of the object stone sculpture

(top) and the shaded image of the modeled result (bottom)

Figure 14: Underside photograph of the scarab beetle stone

engraved with hieroglyphs (left) and the shaded image of

the scene-modeled result. The pictorial image is similar but

not the same as the modeled depth image.

ICINCO 2005 - ROBOTICS AND AUTOMATION

158

the 0.015mm resolution.

The modeling accuracy depends on the rotational

and translational positioning, and distance-sensing.

The mal-aligned positioning results in a shape

distortion, but still generates topologically stable

models.

4 CONCLUDING REMARKS

A simple, automatic, geometrically accurate,

topologically stable, robust and noise-resistive object

modeling, with matrix format meshes, to be followed

by quantitative 3D shape processing, is proposed.

Most of the reconstruction procedures from the

unorganized set of points are based on the principle:

“retrieving surface topology from surface geometry.”

In general, “retrieving topology from geometry,”

where appropriate distance-based criteria are used for

the modeling, is not easy especially in the presence of

noise even in the dense data-sets. Our topology, on

the contrary, is not dependent on geometry. In our

procedure, “topology is first assigned in the scanning

stage and geometry follows.” The noise problem is

inherent in the triangulation scanning, which is fatal

in the ICP algorithm due to point-connection

(topology) ambiguities caused by the problem, is

solved using the matrix format smoothing operators

for practical usage in the exchange for some spatial

resolution reduction.

The matrix format of the modeled data is intuitive

and easy to apply to the quantitative shape

modification using the various matrix type 3D shape

modification operators, which recursively include

thus modeled results with the same matrix format.

The 3D shape models are fused together by

convolution. The data format is compatible with that

of the BEM/FEM. The desired meshing, not limited

to triangular, but quadrilateral, hexagonal, and even

n-gonal meshes, is possible in the same way.

A Boolean operation with multi-directional

modeling is currently underway. We expect

considerable utility in the practical approximate

modeling and 3D shape processing.

REFERENCES

Blais, F., 2004, Review of 20 Years of Range Sensor

Development, Journal of Electronic Imaging, 13 (1),

231-240.

Boissonnat, J., 1984, Geometric Structures for Three-

Dimensional Shape Representation, ACM Transactions

on Graphics, 3 (4), 266-286.

Chen, F., Brown, G., Song, M., 2000, Overview of

Three-Dimensional Shape Measurement Using Optical

Methods, Optical Engineering, 39 (1), 10-22.

Dey, T., Goswami, S., 2004, Provable Surface Re-

construction from Noisy Samples, Annual Symposium

on Computational Geometry, In Proceedings of 20th

Annual Symposium on Computational Geometry,

330-339.

Doi, J., Sato, W., Miyamoto, Y., Ando, S., Yamanaka, M.,

2004, Reuse of a Geometric Model for Shape

Approximation, In Proceedings of 2004 IEEE

International Conference on Information Reuse and

Integration (IRI 2004), 174- 179.

Forsyth, D., Ponce, J., 2003, Computer Vision - A modern

Approach, Prentice Hall, New Jersey.

Godin, G., Beraldin, J., Taylor, J., Cournoyer, L.,

El-Hakim, S., Baribeau, R., Blais, F., Boulanger, P.,

Domey, J., Picard, M., Active Optical 3D Imaging for

Heritage Applications IEEE Computer Graphics and

Applications, 22, 24-36, 2002.

Hartley, H.,. Zisserman, A., 2000, Multiple View Geometry

in Computer Vision, Cambridge Univ. Press,

Cambridge, UK..

Levoy,

M., Pulli, K., Curless, B., Rusinkiewicz, S., Koller,

D., Pereira, L., Ginzton, M., Anderson, S., Davis, J.,

Ginsberg, J., Shade, J., Fulk, D., The Digital

Michelangelo Project; 3D Scanning of Large Statues,

In Proceedings of Siggraph 2000, 131-144, 2000.

Mantyla, M., 1988, An Introduction to Solid Modeling,

Computer Science Press, Rockville, Maryland.

Paul J., Besl, P., McKay, D., 1992, A Method for

Registration of 3-D Shapes, IEEE Transactions on

Pattern Analysis and Machine Intelligence, 14 (2),

239-256.

Pauly, M., Keiser, R., Kobbelt, L., Gross, M., 2003, Shape

Modeling with Point-Sampled Geometry, ACM

Transactions on Graphics (TOG), 22 (3), Special issue:

Proceedings of ACM SIGGRAPH, 641-650.

Rusinkiewicz, S.,. Levoy, M., 2001, Efficient Variants of

the ICP Algorithm, In Proceedings of the 3rd

International Conference on 3-D Digital Imaging and

Modeling (3DIM ’01), 145-152.

Scott, W., Roth, G., Rivest, J., 2003, View Planning for

Automated Three-Dimensional Object Reconstruction

and Inspection, ACM Computing Surveys, 35(1),

64-96.

Simple3D, 2005, 3D Scanners, Digitizers, and Software

for Making 3D Models and 3D Measurements,

http://www. simple3d.com/

Turk, G., Levoy, M., 1994, Zippered Polygon Meshes from

Range Images, In Proceedings of SIGGRAPH 1994,

311- 318.

TOPOLOGICALLY ROBUST RECONSTRUCTION OF A 3D OBJECT WITH ORGANIZED MESHING

159