POSE ESTIMATION OF MOBILE MICROROBOTS IN A

SCANNING ELECTRON MICROSCOPE

A cross-correlation based approach using ROI´s

Torsten Sievers, Sergej Fatikow

Division of Microrobotics and Control Engineering, University of Oldenburg

Uhlhornsweg 84, 26111 Oldenburg, Germany

Keywords: mobile microrobots, image processing, scanning electron microscopy.

Abstract: In this paper, current research towards an automated micro/nano handling station using mobile microrobots

is presented. Mobile microrobots with piezo slip-stick actuation and more than one degree of freedom

mostly don't have internal pose sensors; therefore a global sensor is needed. This paper focuses on the pose

estimation of the mobile microrobots. One possibility for fast pose estimation is the application of video

cameras as global sensors. For pose estimation with accuracy even in the nanometer range high resolution

sensors are necessary. In consideration of resolution, image acquisition time and depth of focus a Scanning

Electron Microscope (SEM) is a powerful sensor for high resolution pose estimation. But the use of a SEM

makes high demands on the image processing. High update rates of the pose data for the robot control

enforce a short image acquisition time of the SEM images. Hence the image noise increases, because frame

averaging or averaging of the detector signal is time consuming. This paper presents a method to calculate

the x,y position and the orientation of a micro object in a strongly noised SEM image stream with cross-

correlation in real-time. To make real-time pose estimation possible, only a region-of-interest (ROI) is

correlated with the target pattern. The SEM is almost predestined to work with ROI’s, because the scan area

of the electron beam can be chosen arbitrarily.

1 INTRODUCTION

Micro- and nanohandling covers the field of

handling objects with sizes in the range of µm, sub-

µm and even a few nm. The most important

applications today are microassembly,

semiconductor technology, nanotechnology, material

research, medicine and biology. Within the last years

a trend towards the automation of nanohandling

processes emerged (Nakajima et al, 2004, Yang et

al, 2003). The nanohandling station that is currently

being developed aims at performing diverse

nanohandling operations in the vacuum chamber of

SEM by several mobile microrobots. In the next

sections an experimental set-up as well as the visual

sensor system architecture for an SEM-based

nanohandling station is presented. The focus will be

the image processing algorithms that determine the

poses of the mobile microrobots. The pose

information is directly used as visual feedback for

telemanipulation or by the control system of the

workstation (Garnica et al, 2003).

2 EXPERIMENTAL SETUP

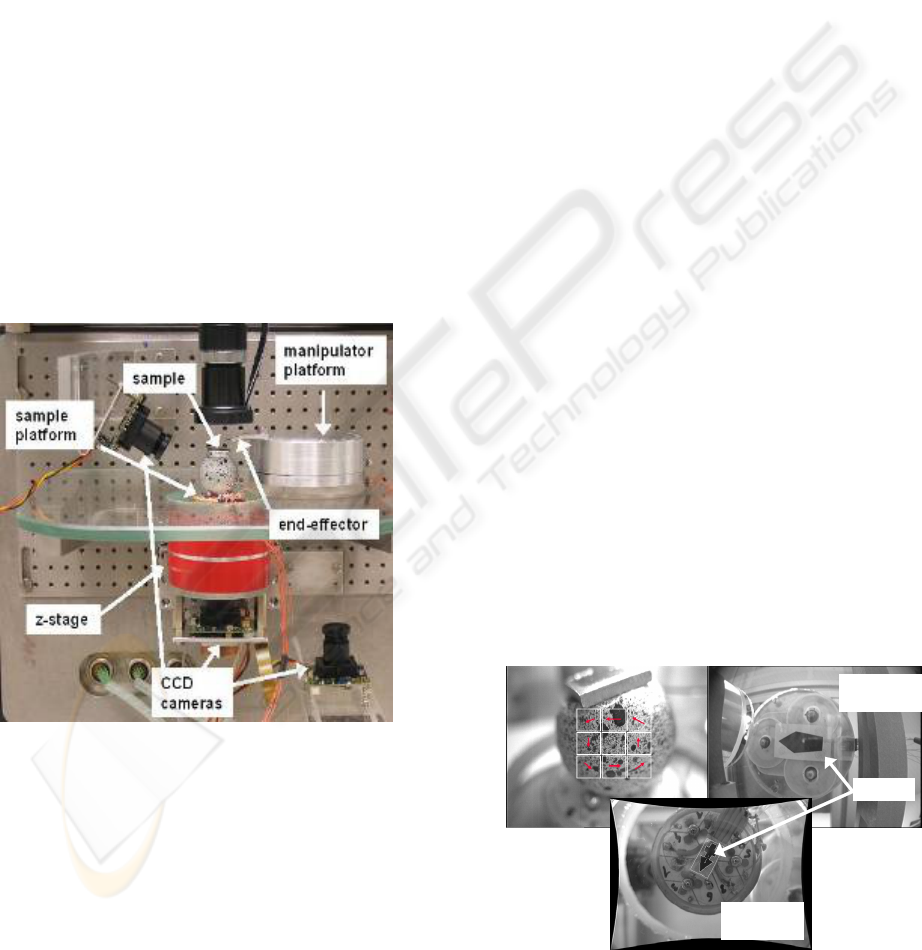

The setup of the mobile microrobot-based

nanohandling station, which has been used, is

depicted in Fig. 1. For an easy handling, the setup is

mounted on a removable SEM door for LEO 1450.

In detail, the setup mainly consists of mobile

microrobots, a linear z-stage and a visual sensor

system consisting of cameras and the SEM. The

concept of the presented setup is that a mobile

platform works as sample holder to move a sample

in the correct pose in the field of view of the SEM.

A second mobile platform carries micro/nano tools

like micro grippers or AFM tips for the manipulation

of the sample. In (Kortschack et al, 2004) the

functionality and characteristics of the mobile

193

Sievers T. and Fatikow S. (2005).

POSE ESTIMATION OF MOBILE MICROROBOTS IN A SCANNING ELECTRON MICROSCOPE - A cross-correlation based approach using ROI´s.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 193-198

DOI: 10.5220/0001178201930198

Copyright

c

SciTePress

platforms has been described. The high-level control

architecture and low-level control algorithms are

presented in (Hülsen, 2004).

The sample holder consists of a mobile platform

moving on a glass plate. This glass plate can be

moved in z-direction via a piezo actuator

(PiezoMotor™) with a traveling range of 2 cm. For

the pose estimation of the z-position the optical

sensor Mercury 3000V from MicroE™ has been

used. Both mobile platforms (stage platform with

sample holder and manipulator platform) are built up

on the stick slip principle and have three degrees of

freedom – two translational and one rotational.

Additionally, on top of the stage platform

another platform has been mounted upside-down.

However, instead of using it as a translational stage,

a metal sphere is put on the ruby spheres. This

sphere serves as the sample holder. By applying a

saw-tooth voltage to the piezo discs, the upper

platform is able to rotate the sphere around three

axes, whereby only two rotational movements are

allowed by the control software.

Figure 1: Setup of the mobile microrobot based

nanohandling station (outside the SEM)

In summary, the whole stage has seven degrees

of freedom, whereby one rotational degree is

blocked by the control software.

To begin a manipulation process, the sample to

be manipulated and the manipulator have to be

positioned in field of view of the SEM. First, the

sample is positioned by the sample platform, and

then the manipulator is positioned in the center of

the SEM image. The positioning tasks for both

platforms are divided into the two sub task coarse

and fine positioning. Coarse positioning is carried

out with visual feedback from CCD cameras (sec. 3)

and fine positioning by processing SEM images

(sec. 4).

3 VISUAL SENSORS

Because of the fact that the mobile platforms have

no internal position sensors analogue CCD cameras

with PAL resolution (768x576 pixels) have been

used to determine a global pose (x, y, φ). Each

camera is equipped with an IR-LED ring light.

Because the secondary electron detector of the SEM

is sensitive to light in the visual spectrum infrared

LEDs are necessary. One approach for the

automated coarse positioning of a mobile microrobot

has been described in (Fatikow et al, 2004).

Pose estimation of the micro robot has been

achieved by a small marker placed onto the

underside of the robot, which will be tracked (Fig.

2). The estimated poses of the micro robot are

represented as a string and sent to the control PC by

TCP/IP communication protocol. The approach

described in (Fatikow et al, 2004) used the

Geometric Model Finder (GMF) of the Matrox

Imaging Library 7.5 (MIL) to determine the

orientation of the mobile platform

(www.matrox.com). With this algorithm a resolution

better than 0.5 mm is possible, which will be

sufficient to position the microrobot’s end-effector

into the scan-field of the SEM, if the magnification

of the SEM is low. The algorithm allows a sensor

update rate of 15 poses per second, by using a

standard PC (2.6 GHz) (Fatikow et al, 2004).

marker

manipulator

platform

sample

platform

marker

manipulator

platform

sample

platform

Figure 2: View from the CCD cameras (top left: sphere,

top right: manipulator platform, bottom: sample platform)

ICINCO 2005 - ROBOTICS AND AUTOMATION

194

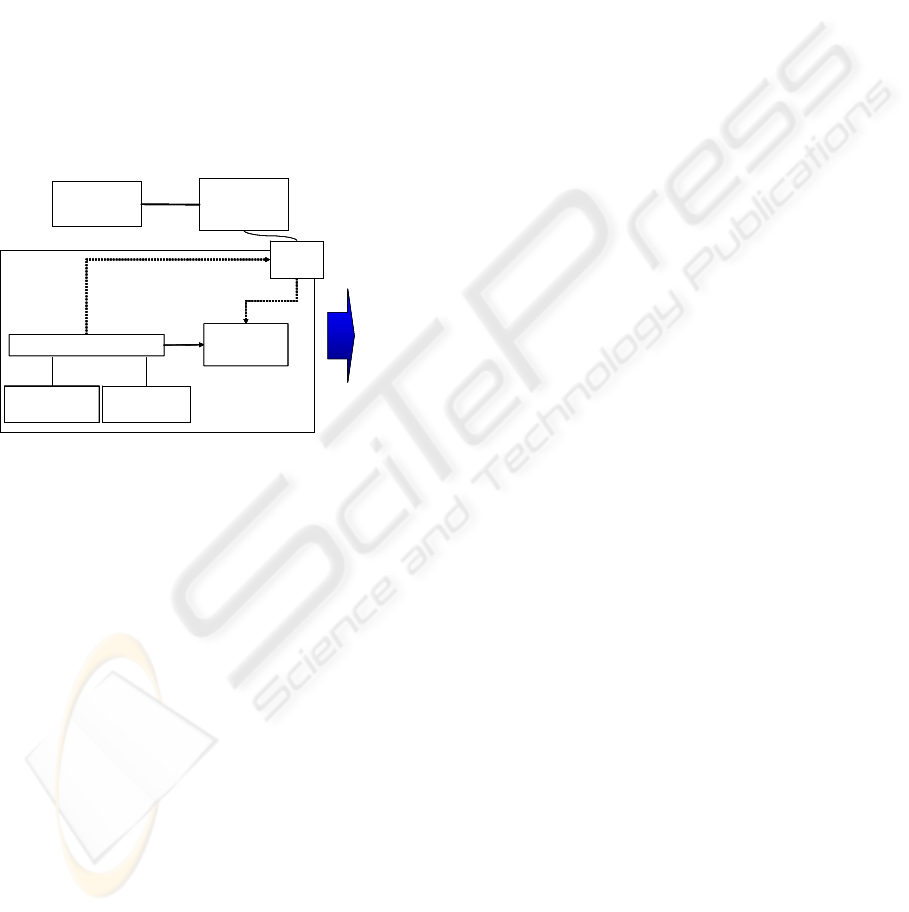

The requirement for live processing of SEM

images is a fast access to the digitized images. We

are using two SEM´s in our lab, a Zeiss DSM 950

and a LEO 1450. The Zeiss DSM 950 has no built-in

digital image acquisition. Thus we are using

additional hardware from point electronic™ with an

external beam control and digital image acquisition

via a PC interface (www.pointelectronic.de) (Fig. 3).

Although the LEO 1450 is equipped with a digital

image acquisition the point electronic hardware is

used, too, because no software interface for directly

accessing the images and controlling the electron

beam is delivered by the SEM vendor. A second

advantage of using the point electronic hardware for

both devices is that the developed software doesn't

have to be SEM specific.

x,y,φ

RAM

SEM

control lib.

Image

Acquisition

Hardware

USB

2.0

Application

beam control

images

image proc.

lib.

SEM

x,y,φ

RAM

SEM

control lib.

Image

Acquisition

Hardware

USB

2.0

Application

beam control

images

image proc.

lib.

SEM

RAM

SEM

control lib.

Image

Acquisition

Hardware

USB

2.0

Application

beam controlbeam control

imagesimages

image proc.

lib.

image proc.

lib.

SEM

Figure 3: Setup of the image processing system

4 POSE ESTIMATION WITH SEM

IMAGES

4.1 Region of interest

Due to the fact that the control system needs the

position and orientation e.g. of an end-effector, the

scan speed of the SEM has to be well above 1 frame

per second. Approximately 10 poses per second is a

good data rate for the control system. However, this

leads to low image quality and noisy images.

Therefore a trade-off between image quality and

scanning speed is looked for. A good solution to find

such a trade-off is the definition of a Region of

Interest (ROI), which can be done with the digital

SEM hardware with software interface from point

electronic. Using ROI's is common in image

processing especially in visual tracking to decrease

computational costs, but with a SEM as sensor

The advantage of the ROI is that the electron

beam of the SEM scans only a small part of the

whole scan field. This leads to a higher scan speed,

whereby the image acquisition time can be

decreased. In addition, the ROI can be defined in a

way that only the interesting object is in the ROI.

This leads to a matching of the target without any

miss matches. If the target is moving, then a new

ROI will be defined around the centre of gravity of

the next pattern match. Only in the worst case that

the target can’t be determined, the whole scan field

will be used again. With this technique the

processing speed and the robustness of the algorithm

can be improved.

4.2 Cross-correlation

Powerful methods for object detection and position

estimation in extremely noisy images are correlation

techniques. Detailed work regarding correlation

based techniques for processing noisy images and

many applications are presented in (Goudail,

Réfrégier, 2003). In this paper the application of

correlation to SEM images is described.

Correlation is a very useful method to find

objects in extremely noisy SEM images. The

disadvantage is a high computational cost, which

will increase with the image resolution. If

orientation and scale of the target object are needed

the computational cost will increase further. Hence,

there are limits when applying correlation to real-

time object tracking. With the use of ROI´s, as

described in the previous chapter, the performance

drawback can be overcome. A solution for the

estimation of the orientation is presented in the next

chapter.

POSE ESTIMATION OF MOBILE MICROROBOTS IN A SCANNING ELECTRON MICROSCOPE - A

cross-correlation based approach using ROI´s

195

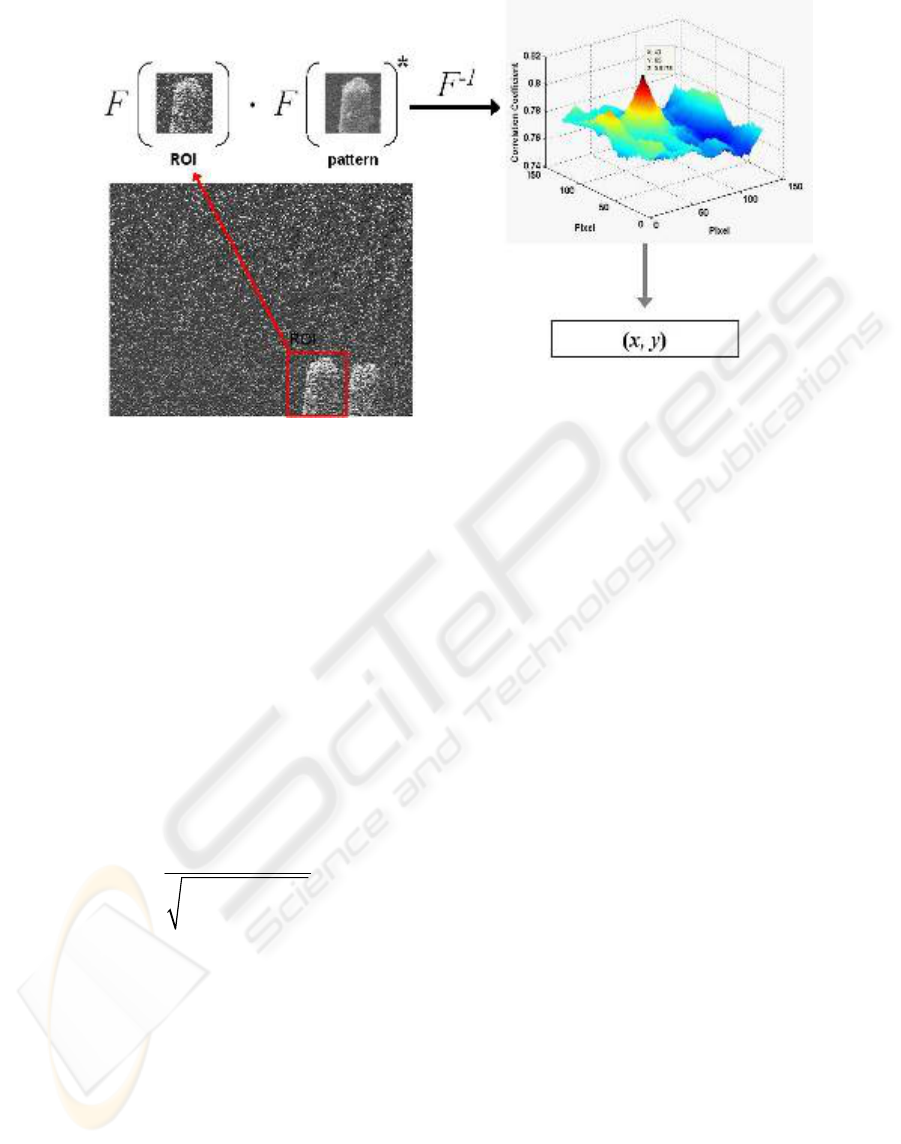

Figure 4: SEM image (640x480 pixels) of the gripper with an acquisition time of 0.1s (lower left). The pattern is an average

of 10 images with a size of 128x128 pixels. The gripper is described in (Mølhave et al., 2004)

The result of a cross correlation between two

images is a matrix which shows possible

displacements of similar input images. Cross

correlation is defined as (Weisstein):

1*

CIPF

−

⎡⎤

=⋅

⎣⎦

Where I is the Fourier transformed of the input

image i and P

*

is the complex conjugated of the

Fourier transformed of the target pattern p. F

-1

denotes the inverse Fourier transformation and C the

correlation coefficient matrix. To get the correlation

coefficients in the range [-1...1] normalization is

needed:

22

k,l k,l

k,l k,l

1

N

ip

=

⋅

∑∑

This leads to the normalized cross correlation

matrix:

N

CCN

=

⋅

If the maximum value of C

N

is equal to 1, both

images are completely correlated. The combination

of using cross correlation with ROI’s is depicted in

figure 3.

If the maximum exceed a predefined threshold,

the position of the maximum peak of the correlation

matrix defines the position of the gripper.

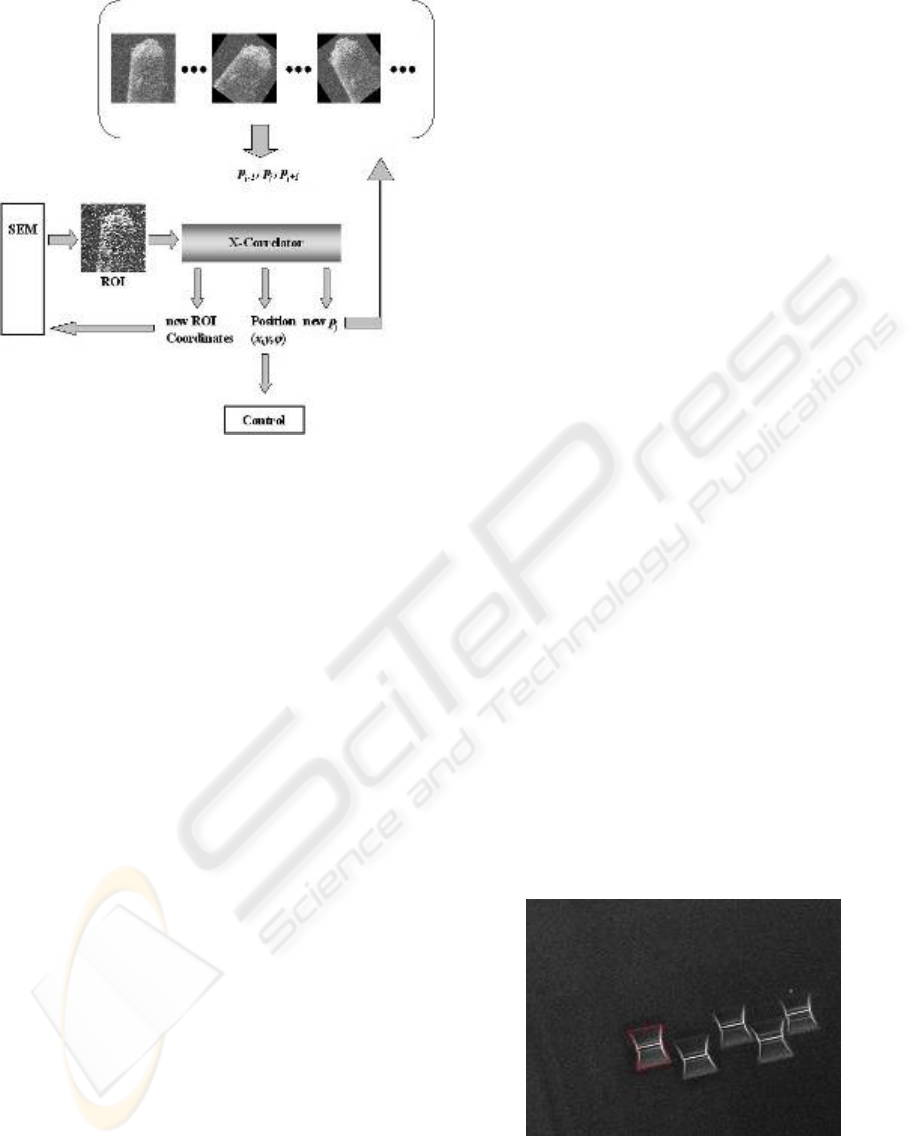

4.2.1 Orientation estimation

The estimation of the orientation of the gripper with

cross correlation is more complex. One possibility is

correlating the input ROI with rotated patterns. Thus

the time consumption for the pose estimation will

increase strongly. To limit this disadvantage the

maximum number of correlations per slope cycle has

been restricted. Therefore a pattern vector has been

generated with 360 components, each rotated by one

degree. For every slope cycle only three adjacent

patterns (p

j-1

, p

j

, p

j+1

) will be selected from the

pattern vector and are correlated, where j denotes the

angle. If the starting orientation is known, the

pattern p with the same orientation and the patterns

with +1° and -1° are chosen. For every slope cycle

the pattern with the maximum correlation will be

estimated and set as p

j

. Subsequently the new p

j-1

and p

j+1

are selected. The flow diagram of the

algorithm is depicted in figure 4. To detect rotations

with more than 1 degree between two frames the

orientation estimation is repeated a few times for the

current frame. If the cross-correlation coefficient for

p

j+1

(respectively p

j-1

) is smaller than p

j

, the correct

orientation is estimated.

ICINCO 2005 - ROBOTICS AND AUTOMATION

196

Figure 5: Cycle of the pose estimation algorithm using

cross correlation

The limit of this approach is that only continuous

orientation changes can be measured. Orientation

changes between two frames with more than a few

degrees cannot be tracked fast enough. For the pose

estimation of an end-effector mounted on a mobile

platform, this drawback is negligible because only

slow rotations are possible.

4.2.2 Start ROI

To start the tracking, the target pattern has to be

found in the full size SEM image. The starting

problem can be solved by using the algorithm

described above. Therefore, the SEM image is

separated into sub images, each with the same size

as the pattern. Experiments carried out so far have

shown that an overlap of the sub images isn't

necessary. Generally, an overlap of some pixels is

meaningful to make sure that the correct target will

be found. For every sub image and every component

of the orientation pattern vector the cross-

correlation has to be calculated. The position of the

maximum of the sub image with the highest

correlation is set as the centre of the start ROI.

The disadvantage of this approach is the high

computing time, which depends on the size of the

image and the pattern. One possibility to speed up

the estimation of the start ROI is image resizing.

Decreasing image and pattern by a factor 8, for

example (640x480 → 80x60 pixels and 128x128 →

16x16 pixels), results in an approximately 8 times

faster ROI estimation. To reduce the number of

calculations the number of components of the

pattern vector has been reduced to 18. The accuracy

loss has been compensated by one succeeding cross-

correlation calculation with full resolution (ROI and

pattern with 128x128 pixels) and complete pattern

vector. Another possibility is a hierarchical search in

the frequency domain. But if only one resize step is

needed the performance difference is negligible

5 RESULTS

The algorithm has been tested with two micro

objects, a gripper and TEM-lamellae. The gripper is

mounted on the manipulator platform and the wafer

with the lamellae is fixed on the sample platform. In

the presented case the frame rate of the SEM is set to

11 fps (frames per second) with an image resolution

of 640x480. Frame averaging is switched off, thus

all frames have been captured with the worst quality.

The 128x128 pixel patterns have been generated by

averaging 10 frames. In figure 3 an image of the

gripper can be seen. The TEM-lamellae is depicted

in figure 5. The captured sequence is a typical visual

servoing task for mobile microrobots of the

nanohandling cell, presented in Sec.1. First, a micro

or nano object has to be positioned to a predefined

pose in the SEM image automatically. Accordingly,

the manipulator tool has to be positioned close to the

object. Because the accuracy of the coarse

positioning is too low, three SEM magnification

steps with different patterns will be used. Changing

the magnification of the SEM doesn't lead to a break

in the automation process, because the LEO 1450 is

equipped with a remote control via RS232.

Figure 6: TEM-lamellae with box dimension of 18µm x

10µm

The accuracy of the pose estimation is 1 pixel

for the x,y position, which means approximately 40

POSE ESTIMATION OF MOBILE MICROROBOTS IN A SCANNING ELECTRON MICROSCOPE - A

cross-correlation based approach using ROI´s

197

nm in real world coordinates. The accuracy of the

orientation estimation is 1°. The computation speed

depends strongly on the pattern size and the number

of cross-correlations per frame. In the presented case

the average number of cross-correlations per frame

is between 3 and 4. With a standard PC (P4, 2.6

GHz), the computation time is 0.02 s for one pose

estimation without orientation calculation and

approximately 0.07 s with orientation. With a SEM

frame rate of 10 fps real-time capability has been

demonstrated. Only for the first frame 0.8 s are

needed to determine the start ROI.

The acquisition time for one pixel is 250 ns.

Therefore the minimum image acquisition time for a

128x128 ROI is about 4.1 ms. The user can chose

between a high frame rate with low image quality

and a slower frame rate with better image quality. In

general, one should adopt the frame rate to the

processing time of the pose estimation algorithm.

Therefore an adaptive scan speed has been

implemented.

The disadvantage of the cross correlation

approach is that changes of the targets shape are

hard to recognize. For every magnification of the

SEM, the pattern has to be adapted, because the

scale of the target changes with the magnification. If

only few magnification steps are used this problem

can overcome by using additional patterns. A more

serious problem is shape variation by deformation,

e.g. while a gripping process.

6 CONCLUSION

The real-time pose estimation of micro- and

nanoobjects inside a SEM image stream requires

image processing algorithms with high robustness

against noise. Cross correlation is a powerful

method to overcome this problem. The disadvantage

that computation time is very high can be

compensated by using ROI’s. Here an advantage of

the image acquisition process of SEM’s can be used.

Because only a small region will be scanned, one

can choose between high image acquisition speed

and high image quality in comparison with a full

size scan. Overall this leads to real-time capability

for the sensor system. The presented approach

enables automatic positioning of mobile microrobots

with nanometer resolution, which is a further step

towards automatic nanohandling.

ACKNOWLEDGMENT

This paper is based on research work supported by

the European Union; project ROBOSEM (GRD1-

2001-41864).

REFERENCES

Yang, G., Gaines, J. A., Nelson, B.J., 2003. A supervisory

wafer-level 3D microassembly system for hybrid

MEMS fabrication, Journal of Intelligent and Robotic

Systems, nr. 37, Kluwer Academic Publishers, pp. 43-

68

Nakajima, M., Arai, F., Dong, L., Nagai, M., Fukuda, T.,

2004. Hybrid Nanorobotic Manipulation System

inside Scanning Electron Microscope and

Transmission Electron Microscope, Proc. of IEEE/RSJ

Int. Conference of Intelligent Robots and Systems, pp.

589-594

Garnica, S., Hülsen, H., and Fatikow, S., 2003.

Development of a Control System for a Microrobot-

Based Nanohandling Station, Proc. of 7th Int. IFAC

Symp. on Robot Control (SYROCO), Wroclaw,

Poland, pp. 631-636

Kortschack, A., Fatikow, S., 2004. Development of a

mobile nanohandling robot, Journal of

Micromechatronics, Volume 2, Nr. 3, pp. 249 – 269

Hülsen, H., 2004. Design of a fuzzy-logic-based

bidirectional mapping for kohonen networks. In Proc.

Int. Symposium on Intelligent Control (ISIC’04),

Taipei, Taiwan.

Fatikow, S. et al., 2004. Versatile Nanohandling Robot

Cell in a Scanning Electron Microscope, 12th

Mediterranean Conference on Control and

automation.

www.pointelectronic.de

Goudail, F., Réfrégier, P., 2003 Statistical Image

Processing Techniques for Noisy Images – An

Application-Oriented Approach, Kluver Academic /

Plenum Publisher.

Weisstein, E.W. "Cross-Correlation Theorem." From

MathWorld--A Wolfram Web Resource.

http://mathworld.wolfram.com/Cross-

CorrelationTheorem.html

Mølhave, K., Hansen, T. M., Madsen, D. M. and Bøggild,

P., 2004. Towards Pick-And-Place Manipulation of

Nanostructures, Journal of Nanoscience and

Nanotechnology, 4, 279-282

ICINCO 2005 - ROBOTICS AND AUTOMATION

198