Proposal Model for Stamping Application Using

Artificial Neural Networks System

Noureddine Ben Yahia, Sabeur Abid and Ali Zghal

ESSTT, University of Tunis, 5 avenue Taha Hussein, Montfleury,1008 Tunis, Tunisie;

Abstract. In this research, the approaches of feature stamping design and

Artificial Neural Networks (ANN) are combined to automate the process

planning task and to generate process groups for set-ups. The model created in

Computer Aided Process Planning (CAPP) system can provides different

process using ANN for cylindrical parts. This model is composed by three

principal modules, the first relates to geometrical in 3D modeling, the second

treats calculations of the stamping process parameters and the third module

proposes the processes of obtaining a final part using ANN system. The

development of this system is based on the experiments and the knowledge to

make specialists in this field. Indeed in this work we started with a theoretical

study concerning the influence of the parameters of stamping and the causes of

the principal defects of an operation of working of the cylindrical parts and the

proposal for several typical examples of processes which are validated with

industrialists. In this work we focus only in ANN structure for this application,

what is Input? What is output ? to give industrial solution. The proposal method

can substantially reduce the time needed to generate process plan and the results

are of consistentquality.

1 Introduction

Computer Aided Design and Manufacturing (CAD/CAM) technologies have evolved

over the last decade to automate and integrate various stages of the product cycle to

improve the productivity of the conventional design and manufacturing activities. In

typical product development processes, the manufacturing process passes by several

stages in the manufacturing companies. The research works is directed to the

automation of manufacture, such as the automatic range in machining, folding, cutting

like in stamping. The automation of stamping forms the object of this research [1, 9,

10, 13].

Furthermore Process Planning is the critical bridge between design and

manufacturing. Design information can be translated into manufacturing language

only through process planning.

In this paper, we present an intelligent CAPP methodology based on trained Artificial

Neural Networks which help the designer to choose the sequence of stamping

operations based on the attribute of feature components and matrix [6, 8].

The paper is organized as follows. In section 2 we describe the problem of stamping

process planning, while in section 3 we present the model for design by feature. In

Ben Yahia N., Abid S. and Zghal A. (2005).

Proposal Model for Stamping Application Using Artificial Neural Networks System.

In Proceedings of the 1st International Workshop on Artificial Neural Networks and Intelligent Information Processing, pages 103-111

DOI: 10.5220/0001177001030111

Copyright

c

SciTePress

section 4 we propose the new neural method for automated stamping process. Finally

in section 5 we give a conclusion and perspectives.

2 Problem Formulation

The traditional method of process planning is centered on the “process planner”. The

process planner typically needs diverse applied knowledge in both design and

manufacturing and uses this knowledge, past experience, handbooks and/or various

databases to translate the product engineering requirements into detailed

manufacturing.

Examining the recent developments in CAPP, it can be observed that is now in a

strategic position. Key research issues of CAPP must include:

- Development of methodologies for complete product definition that

captures the design, functional, and manufacturing aspects of the part,

- Automation of process planning knowledge acquisition with artificial

intelligence pradigms,

- Development of intelligent interface between CAD and CAM.

3 Model for Design by Features

3.1 Knowledge Base for Process Planning

The first part of this paper presents a new methodology for the description of the

profile aimed job. This method is called Job kind in dynamic study, known as ETED

[5].

The analysis of a knowledge planner consists to extract the knowledge of the expert

that it has acquired in general by an initial training of professional experience

displayed on several years, perhaps of tens years. This task of knowledge experts

extraction is the spring of an analyst. This analyst is capable to identify the different

real problem types well often complex that pose. It has to find methods of

representation of real closest environment.

In our case of study, we are placed in the context of a workshop producing in middle

and/or big batch size of various pieces that are composed by several cylindrical parts.

Following this, we have constituted a sample of persons to inquire, that represent

several activities :

- The use of mechanical factories including the operators on numerical machine-tool,

the planner and the expert in stamping,

- Mechanical teachers for, technological institutes, professional training centers and

study offices which are specialized in CAD/CAM solutions.

From centering of the planner’s competence, we proceed directly to the individual

which concerns the deciphering of the function of CAPP applied on cylindrical parts.

Waited results of these meeting are:

- identify constraints used during the elaboration of manufacturing plan,

104

- identify the order of constraints according to their importance,

- determine the organization of sequences operations for stamping parts,

- determine of the choice criteria for operations organization in dimensions and in

constraint function,

- determine criteria of the choice of manufacturing tools for cylindrical features

3.2 Feature Based Modeller

The results of Process Planing Knowledge base concerns the creation and

manipulation of manufacturing feartures for each free types or interaction between

them. The feature modeller is based on standard STEP [5].

In this work, features are considered to be regions of a part having some

manufacturing significance. The particular manufacturing context consider a stamping

features. In our examples we have developed 12 cylindrical features denoted: F1, F2,

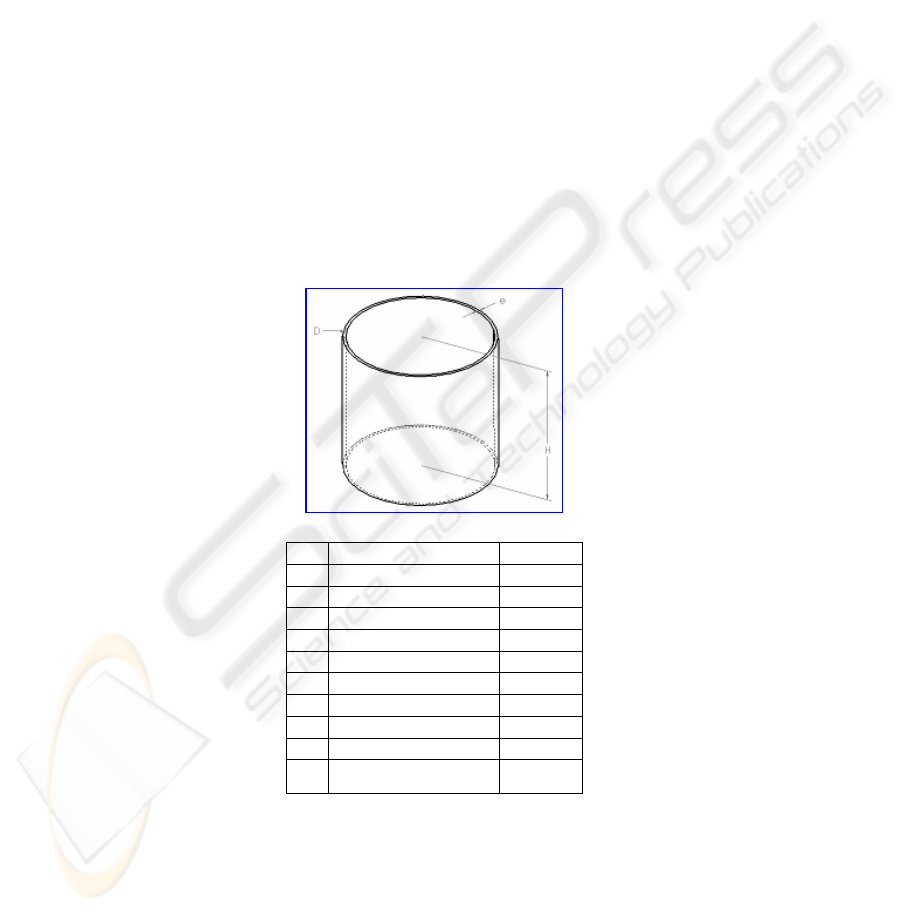

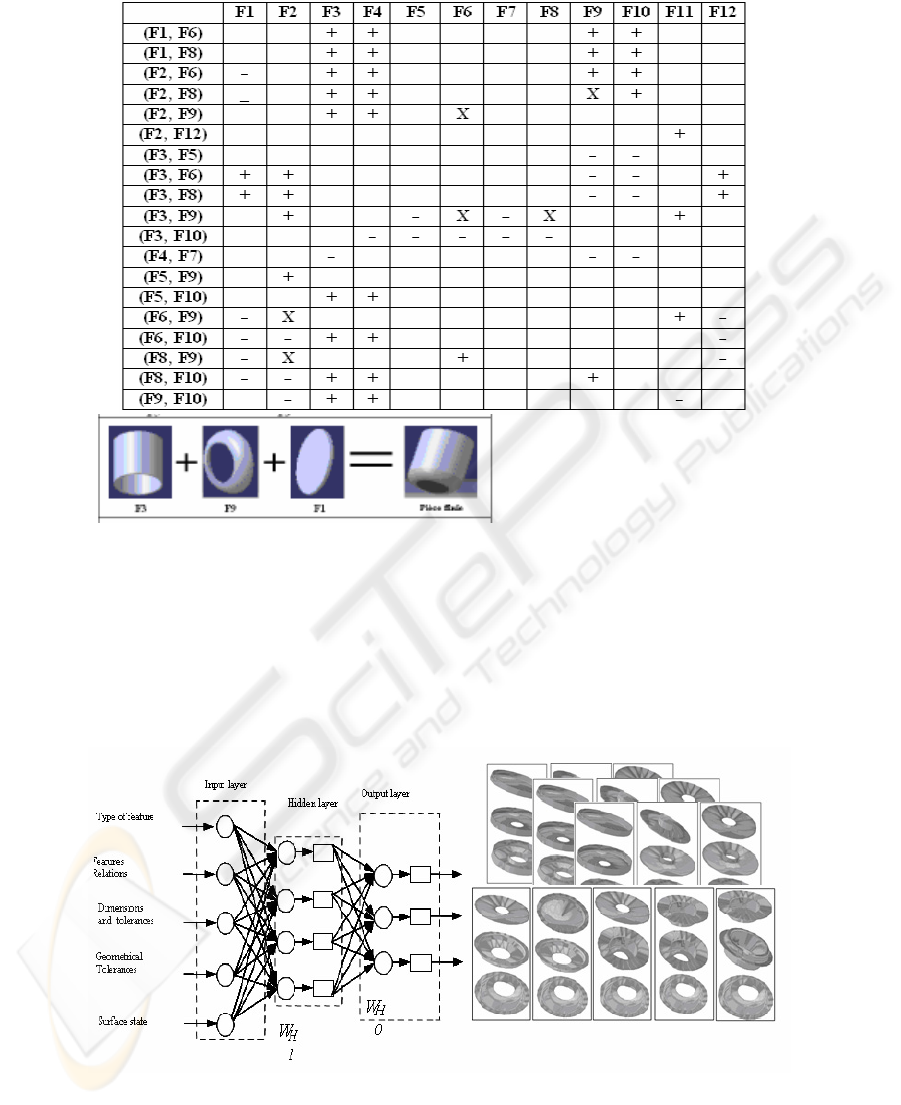

F3,….F12. Each feature is composed by a set of attributes. In figure 1 and 2 we give

tow examples (F3, F9) of features and their attributes.

In this work we consider cylindrical parts. Each part is composed by one or some

cylindrical features (figure 3).

In the following we will describe the Neural Network method for process

organization.

N° Attributes

1 Code F3

2 Number 1

3 diameter D

4 Width e

5 Height H

6 Orientation (0,0,1)

7 Tolerance (e) IT(e)

8 Tolerance (H) IT(H)

9 Tolerance (D) IT (D)

10 Position A3

Fig. 1. Feature F3

105

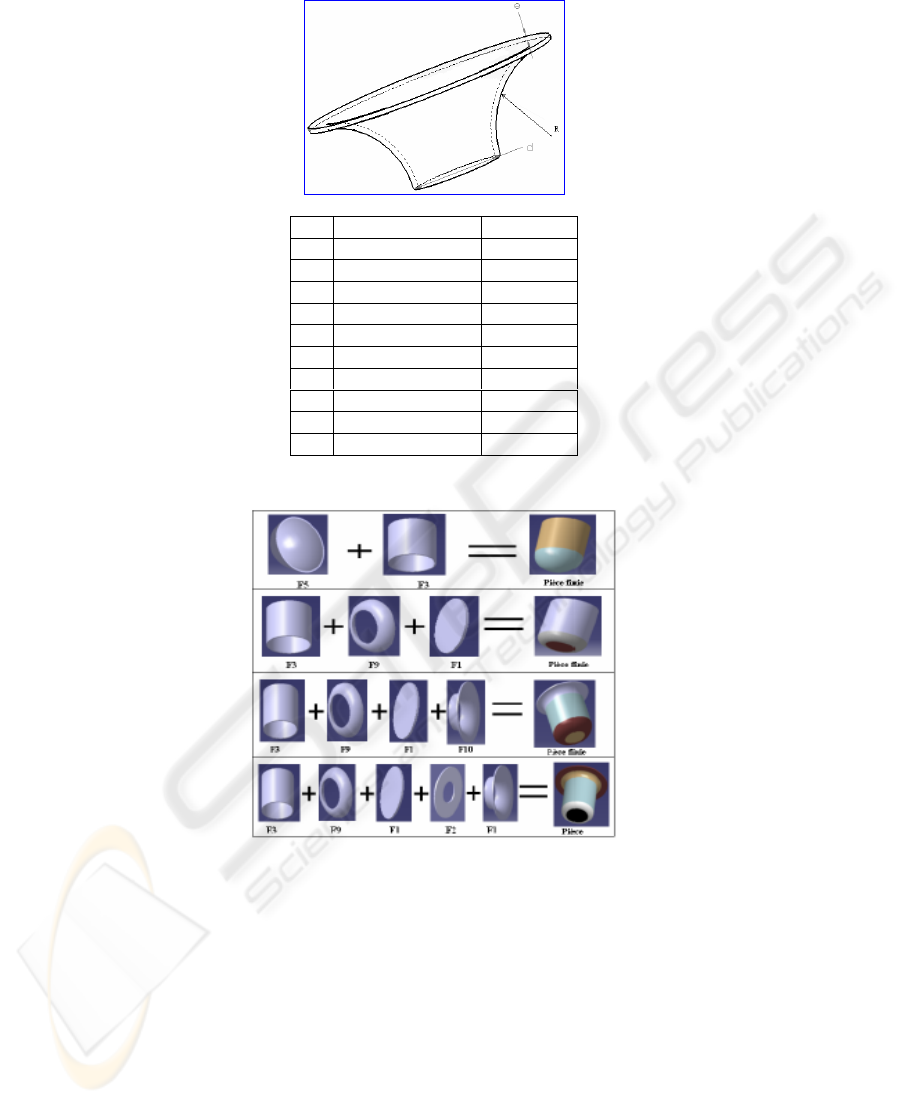

N° Attributes

1 Code F9

2 Number 1

3 Radius R

4 Width e

5 Diameter d

6 Orientation (0,0,-1)

7 Tolerance (e) IT(e)

8 Tolerance (R) IT(R)

9 Tolerance (d) IT (d)

10 Position A3

Fig. 2. Feature F9.

Fig. 3. Examples of composed features

4 New ANN Method for Automated Stamping Process

4.1 Neural Networks Architecture

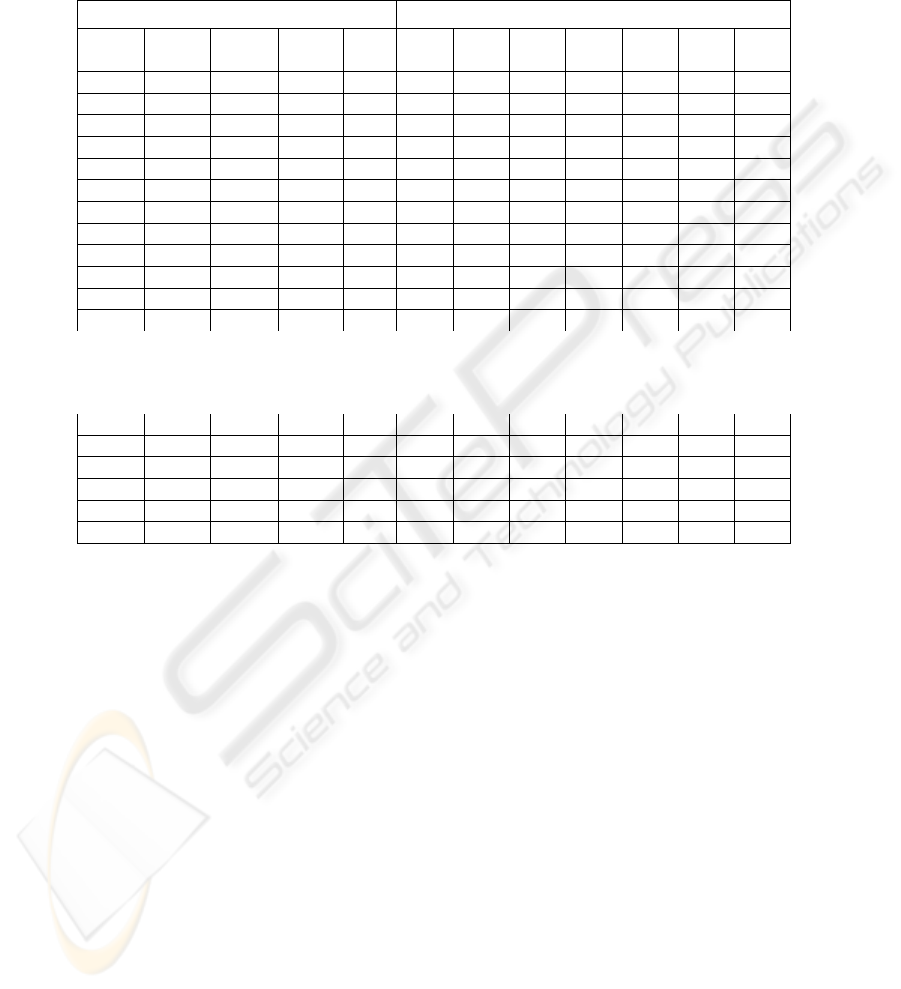

In this section, we present a method of process organization of manufacturing by

using an Artificial Feed-Forward Neural Networks system where the learning

mechanism is the backpropagation algorithm [2, 3, 4, 7].

106

The basic Neural Networks architecture includes an input layer of neurons that

receive the binary or continuous valued input signals, a number of hidden

(intermediate) layers that are highly interconnected and output layer with one or more

neurons [9, 10, 11].

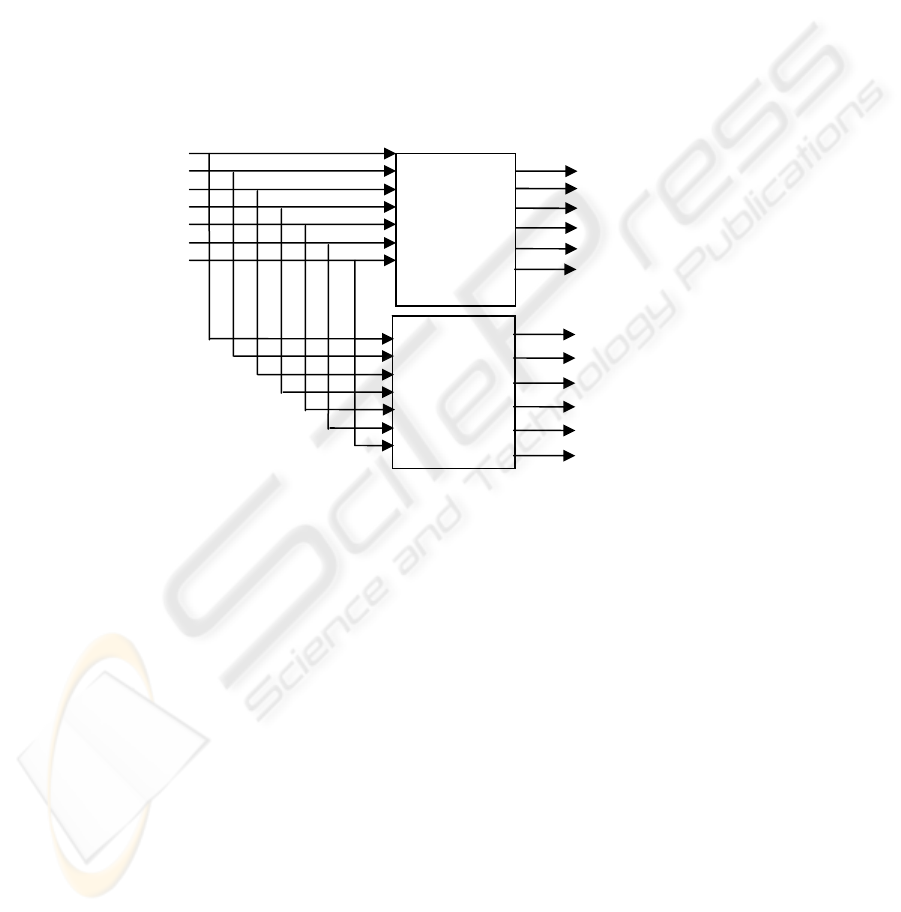

The global system for process planning is composed by two related Neural Networks

(NN1 and NN2) with a parallel structure (Figure 4):

- NN1 is capable to select a machining operations:

A stamping operation is attributed to a previously recognized manufacturing features.

The choice is made according to specific technological knowledge and is based on

rules following geometric and tolerance considerations [14].

- NN2 is capable to select machining tools to be used:

The same logic is applied to each operation and feature, and the appropriate

machining tools are selected. Outputs of the Neural Networks system constitute a

matrix, which is represented by binary form.

Fig. 4. Global Neural Networks architecture

NN1 architecture is composed by five elementary Neural Networks (NN11, NN12,

NN13, NN14, NN15) given in Figure 5.

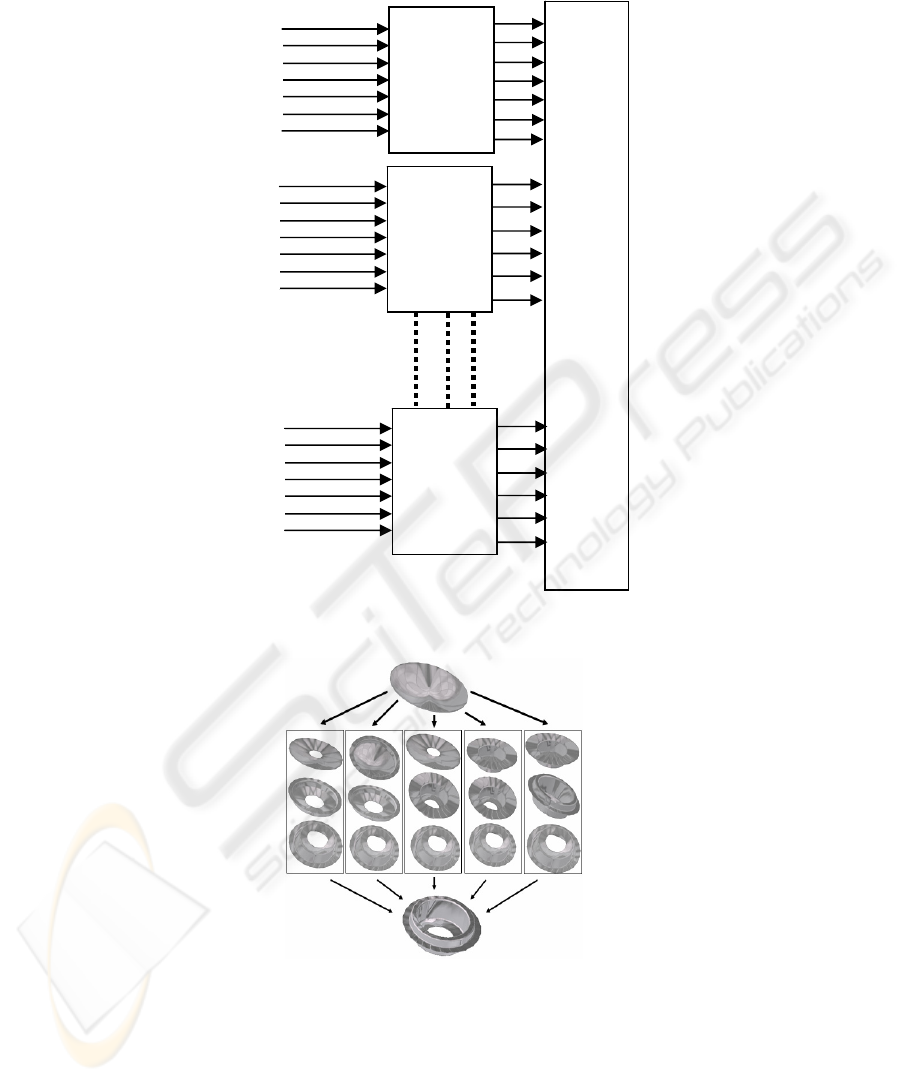

In Figure 6 we propose one example of outputs of neural Networks NN1. this system

can provide five process possible for the same final shape but we don’t have the same

tools.

Process 1

Process 2

Process 3

Process 4

Process 5

Process i

Class Tool. 1

Class Tool 2

Class Tool 3

Class Tool 4

Class Tool 5

Class Tool 6

Class Tool i

Features

NN1

NN2

107

Fig. 5. Architecture for NN1

Fig. 6. Output of NN1 system

In order to prepare database for NN1 system we have to construct matrix for each

composed parts with cylindrical features. For example in figure 7 we consider three

simple elements to construct a final cylindrical parts.

Features

Features

Features

NN11

NN12

NN15

Process Planning for Features,

Elémentaries and interaction Features

108

(-): First element added to the part

(+): last element added to the part

(X): the third element added can be

the first or the last element of the

part

Fig. 7. Example of matrix parts with three simple elements

4.2 Development of Neural Networks System

The structure of the automated choice system for stamping process that we have used

is based on the multi-layer neural networks. They have the advantage of making it

possible with a certain number of tests to model the machining process to prismatic

features by the proposal of the cutting tools (figure 8).

Fig. 8. Example, Neural Networks structure of NN11.

109

For the example of figure 8 we present in the flowing Input and output vectors for

the NN1 system.

The input vector is formed by feature attributes and output vector represent the

automated stamping process (figure 9)

NN1 INPUT NN1 OUTPUT

R

(mm)

h/d

(mm)

d

(mm)

e

(mm)

Ma S01 S02 S03 S04 S05 S06 S07

>d/4 > 0.5 >10 0.2 1 1 1 1 1 1 1 1

>d/4 > 0.5 >10 0.2 2 0 1 1 1 1 0 0

>d/4 > 0.5 >10 0.2 3 0 1 1 1 0 0 0

>d/4 > 0.5 >10 0.4 1 1 1 1 1 1 1 1

>d/4 > 0.5 >10 0.4 2 0 1 1 1 1 0 0

>d/4 > 0.5 >10 0.4 3 0 1 1 1 0 0 0

>d/4 > 0.5 >10 0.6 1 1 1 1 1 1 1 1

>d/4 > 0.5 >10 0.6 2 0 1 1 1 1 0 0

>d/4 > 0.5 >10 0.6 3 0 1 1 1 0 0 0

>d/4 > 0.5 >10 0.8 1 0 1 1 1 1 1 0

>d/4 > 0.5 >10 0.8 2 0 1 1 1 1 0 0

>d/4 > 0.5 >10 0.8 3 0 1 1 1 0 0 0

--- --- --- --- --- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- --- --- --- --- ---

>d/20 >2 > 100 > 2 1 1 1 1 1 0 0 0

>d/20 >2 > 100 > 2 2 0 1 1 1 0 0 0

>d/20 >2 > 100 > 2 3 0 1 1 1 0 0 0

>d/20 >2.5 > 100 > 2 1 0 1 1 1 0 0 0

>d/20 >2.5 > 100 > 2 2 0 1 1 1 0 0 0

>d/20 >2.5 > 100 > 2 3 0 1 1 1 0 0 0

Fig. 9. Matrix of input and output vectors.

5 Conclusion

In this paper we have presented a new method of automated stamping process (CAPP

system) based on Artificial Neural Network.

The development of powerful and flexible CAPP system will be useful to the

manufacturing engineering specialists working in concurrent engineering teams.

The advantage of this new method of process planning is the ability to generate an

optimal sequence which is difficult in a real manufacturing environment.

In the present work, use of Artificial Neural Networks approach has enabled to

develop a very flexible intelligent CAPP methodology that can be easily trained to

handle new types of components. A component with cylindrical features has been

analyzed by this procedure. The methodology presented here can substantially reduce

the time needed to generate process plans and the results are of consistent quality.

110

References

1. A. Zouidi, A. Chaari M. Stambouli and F. Fnaiech 2004 «Nonlinear Continuous Time

Modeling of a High Pressure Mercury Vapor Discharge Lamp Using Feed

2. D. Kiritsis ‘‘A Review of Knowledge-Based Expert Systems for Process Planning.

Methods and Problems’’Advanced Manufacturing Technology 10:240-262. 1995

3. I. Drstvensek et M. Brezocnik ‘‘ On inteligent CAD/CAP Integration Based on feature

Recognition and Evolutionary Computation.’’ IDMME 2000, 3rd International Conference

on integrated Design and Manifacturing for Mecanical ingineering, Cnadien Society for

Mechanical Engineering 2000.

4. J.P.Hao, Y.L. Yu, Q. Xue 2002 « A maintainability analysis visualization system and its

development under the AutoCAD environment” journal of Materials Processing

technology 129 p 277-282, 2002

5. N. Ben Yahia, F.Fnaiech, B.Hadj Sassi 2000 « Application des réseaux de neurones

multicouche pour l’élaboration de phase d’usinages.’’ Conférence international

Francophonie d’automatique CIFA pp6410,645,5-7 juillet 2000

6. N. Ben Yahia et B.Hadj Sassi, 1999 « Elaboration automatique de phases d’usinage basé

sur les réseau de neurones artificielles » Conférence International de Productique ( CPI

99) 25-26 Nov. 1999 au Maroc (FST de Tanger).

7. N. B. Yahia, F. Fnaiech, and S. ABID, "Manufacturing Scheduling using Multilayer

Neural Network", Computational Engineering in Systems Applications CESA'2003, July

9-11, 2003, Lille, France.

8. N. B. Yahia, F. Fnaiech and S. ABID, "Manufacturing Process Planning Application using

Artificial Neural Networks", 2002 IEEE International Conference on Systems, Man and

Cybernetics (SMC'02), October 6-9, 2002, Hammamet, Tunisia.

9. R. Ben Khalifa, N. Ben Yahia, A. Zghal, «Automated selection of machines-tools using

artificial neural networks », 2nd AUS International Symposium on Mechatronics, AUS-

ISM05, April 19–21, 2005, American University of Sharjah Sharjah, United Arab

Emirates.

10. R. Ben Khalifa, N. Ben Yahia, A. Zghal, «Intégration des réseaux de neurones

multicouches pour le choix automatique des machines-outils », 6e Congrès international

de génie industriel – 7-10 juin 2005 Besançon, France.

11. J. Carlos Espíndola Ferreira and A. José Álvares 2003 “CAD/CAPP/CAM integration

methodology for the remote manufacture of cylindrical parts though the web” 17th

International Congress of Mechanical Engineering 03, São Paulo, SP,2003.

12. J. Dunfied, M. Tarbouchi and G. Labonte 2004 « Neural Networks Based control of a Four

Rotor Helicopter » IEEE icit 2004 Yasmine-Hammamet, December 8-10, 2004

13. S. Abid, F. Fnaiech and M. Najim ‘‘A Fast FeedForward Training Algorithm Using A

Modified Form of Standard Back-Propagation Algorithm’’ IEEE Transactions on Neural

Networks, pp. 424-430, March 2001.

14. W. Eversheim, M. Koschig, N. Michalas ‘‘Knowledge-based Technology Data

Management’’The 34th CIRP International Seminar on Manufacturing Systems, 16-18,

Athenes, Greece. May 2001.

111