DETECTABILITY AND DIAGNOSABILITY OF DISCRETE

EVENT SYSTEMS

Application on manufacturing systems

Moamar Sayed Mouchaweh, Alexandre Phillipot, Véronique Carré Ménétrier

Université de Reims, CReSTIC - LAM, Moulin de la Housse B.P. 1039, 51687 REIMS Cedex 2, FRANCE.

Keywords: Discrete Event Systems, Modelling, Diagnosis, Manufacturing systems.

Abstract:

The diagnosis is defined as the process of detecting an abnormality in the system behavior and

isolating its causes or sources. Not all the systems are diagnosable. Thus, before Appling a

method to diagnose a system, we need to know if this system is diagnosable according to the set

of failures required to be detected and isolated. This paper presents an algorithm to determine if a

system is detectable or not, i.e., if we can know, at each instant, whether the system works under

a normal or abnormal functioning state. In the case that the system is detectable, this algorithm

determines if this system is diagnosable. This algorithm combine

s event and state based

approaches in order to maximise the diagnosability power with a minimum number of sensors. In

addition, the time is integrated and modelled with fuzzy intervals to enhance this diagnosabilty

power and to take into account the imprecision of events occurrences instants. An example of

manufacturing system is used to illustrate the functioning of this algorithm.

1 INTRODUCTION

The complexity of industrial systems increases

rapidly while in the same time safety, availability,

reliability, and performances of these systems rise.

Consequently, the potential for system to fail is

enhanced regardless how safe the designs are, how

improved the quality of control techniques are and

how better trained the operators are (Perrow, 1984).

Discrete Event System (DES) is dynamic systems

equipped with a state space and a state-transition

structure. One of the key benefits of a DES is that

there is no need to descretize time and yet one can

capture the asynchronous nature of event processes.

DES is often modelled in using a finite-state

automaton, a Petri net or process algebra. Each

modelling tool has its advantages and disadvantages

depending on the objectives of modelling: model

complexity or natural projection and formalisation

facilities.

When failures occur in a system, observations are

analysed using the system model to generate a set of

possible failures. A failure implicates one or more of

system components and explains all the observed

measurements: deviating and normal. Generally,

failures can be characterized as: permanent or

intermittent. The permanent failures can be divided

into two major kinds: progressive or abrupt. The

type of failures can be classified as: sensor failures,

actuator failures, process failures and control loop or

controller failures.

In this paper, a quick review of major approaches of

failure diagnosis of DES is presented. Since not

every system is diagnosable, these approaches define

a notion of diagnosability based either on event, on

state or both depending on their model and the type

of failures: permanent or intermittent, that they must

detect and diagnosed. Then a method to diagnose

DES is introduced. This method is modular and

decentralized. Before applying this method to

diagnose DES, an algorithm is used to determine if

the process is diagnosable according to the

observable events and for the set of failures to be

isolated. If the system cannot be diagnosed, then

sensor maps must be modified in order to provide

the diagnosability property to the system. Finally, an

example of a manufacturing system is used to

illustrate the diagnosis method with the

diagnosability algorithm.

149

Sayed Mouchaweh M., Phillipot A. and Carré Ménétrier V. (2005).

DETECTABILITY AND DIAGNOSABILITY OF DISCRETE EVENT SYSTEMS - Application on manufacturing systems.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 149-154

DOI: 10.5220/0001176201490154

Copyright

c

SciTePress

2 FAILURE DIAGNOSIS

APPROACHES

There is a great deal of methods for designing and

developing an automated diagnosis system

(Ramdage, 1987), (Su, 2004), (Wang, 2000),

(Cassandras, 1999). A common feature of these

methods is the use of a model to specify the correct

behaviour of the system and then to analyze the

observations of the system current operating state to

detect a failure. The choice of one of these methods

depends on several factors as: the dynamic of the

system (discrete, continuous and hybrid),

implementation standpoint (on line, off line),

information representation (quantitative, qualitative),

system complexity (large or simple) and the depth of

available information about the system

specifications and behaviour (structural, analytical

and heuristic knowledge).

We will focus on the DES failure methods. They can

be classified according to the structure of their plant

and diagnoser models into 3 main categories:

centralized, decentralized and distributed structures.

3 STRUCTURE OF DES FAILURE

DIAGNOSIS METHODS

There are three main structures of plant and

diagnoser models of DES:

1. Centralized approaches: There is one

centralized system model associated with one

centralized diagnoser, which collects observations,

then makes a final decision about the target system’s

fault status. In (Zad, 1998), we can find an example

of these approaches.

2. Decentralized approaches: There is one

centralized system model associated with several

local diagnosers, each of which receives

observations from a specific set of sensors and

makes local diagnosis decision based on such local

observations. A very limited communication is

permitted through a centralized coordinator to solve

the problem of the possible ambiguity between local

diagnoser decisions. In (Sampath, 1994), an example

belongs to this category.

3. Distributed approaches: The system consists of

several local components, and is associated with

several local diagnosers, each of which is usually

responsible for a specific local component. Since

neither a centralized system model nor a centralized

coordinator exists, a pure concurrent communication

among local diagnosers is necessary. In (Su, 2004),

(Holloway, 1994), we can find an example

belonging to this category.

4 DES DIAGNOSABILITY

NOTIONS

The DES failures diagnosis methods can be divided

into two main categories: event-based methods and

state-based methods. In event-based methods,

failures are modelled as execution of certain faulty

events. The DES plant representation is based on a

finite-state automaton. This model accounts for the

normal and failed behaviour of the system. All

information relevant to the diagnosis including

sensors information is captured in the event set of

the model. Typically, the observable events in the

system are one of the following: commands issued

by the supervisor and sensor readings immediately

after the execution of the above command, and

changes of sensor readings. The unobservable events

are failure events or other events which cause

changes in the system state not recorded by sensors.

This model is obtained by a product composition of

finite-state machines models of individual system

components.

A diagnoser is designed to decide whether the

original behaviour contained a fault or not in basing

on sequences of observable events. The diagnoser

should announce a fault at most n steps after the

fault occurred. Once a fault is announced, the

diagnoser cannot stop announcing it (Sampath,

1994).

To enhance the diagnosability, the above framework

is extended to dense-time automata (Tripakis, 2001).

This extension is useful since it permits to model

plants with timed behaviour. It also allows

diagnosers to base their decisions not only on the

sequences of observed events, but also on time

delays between these events.

An event-based method is proposed in (Garcia,

2003) for monitoring and diagnosis of

manufacturing systems. To detect a special event

(failure), a monitoring observer (agent) analyzes

discrete event signals triggered by entities as they

transit through the monitored system. In (Holloway,

1994), (Deepa, 2000) the authors present an

approach to fault monitoring in manufacturing

systems allowing the modelling of process in which

both single-instance and multiple-instance

behaviours are exhibited concurrently. The timed

sequence events generated by the DES under

supervision is compared with a set of specifications

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

150

of normal functioning called templates. These

templates are suitable for manufacturing systems

and can operate independently in parallel.

An equivalent state-based approach is considered

where the occurrence of a failure is modelled as

reaching of certain faulty states (Lin, 1994). This

approach uses a general model for both types of

diagnosis: off-line and on-line. For on-line, a

deterministic Moore automaton with partial state

observation and no event observation is used while

in off-line diagnosis a nondeterministic Mealy

automaton with no state observation and partial

event observation.

In (Zad, 2003) a based state model to realize the

passive diagnosis was proposed. The state set of

system is partitioned according to system condition

(failure status). A diagnoser, based on finite state

automata, estimates the conditions in using the

sequence events and state outputs.

In (Philippot, 2005), we have proposed a method to

realize the diagnosis of DES. In the next, we define

an algorithm to determine if the system is

diagnosable, this algorithm is adapted for our

method and it limits the number of states necessary

to detect actuator-sensor failures as we will see later.

5 PROPOSED APPROACH TO

FAILURE DIAGNOSIS

In (Philippot, 2005), a model-based approach to

diagnose DES is proposed. A mathematical model G

must be constructed to define how system states

change due to event occurrences. The model is

decentralized: the system consists of several local

components (G

i

, i = 1 .. n) with a coordinator to

realize a minimum of communication between these

local components. The diagnoser model is

distributed: several local diagnoser (D

i

, i = 1 .. n) are

constructed, each one of them is usually responsible

for a specific local component. The goal of the use

of decentralized model and a distributed diagnosis is

to reduce the spatial explosion problem at the design

stage and to facilitate the localisation of default

elements.

A notion of diagnosability is defined since not every

system is diagnosable. This notion depends on the

partition required (failures to isolate) and on the

observable events.

To enhance the diagnosability, time is integrated to

this approach. Fuzzy functions, modelling the

minimum and maximum expectation moments

accepted for an event to take place, are computed.

The use of fuzzy intervals is useful to better take

into account the imprecision and uncertainty

attached to the calculation of these moments and to

better model the tractability which can be used to

realize a prognostic, particularly useful for the

progressive failures.

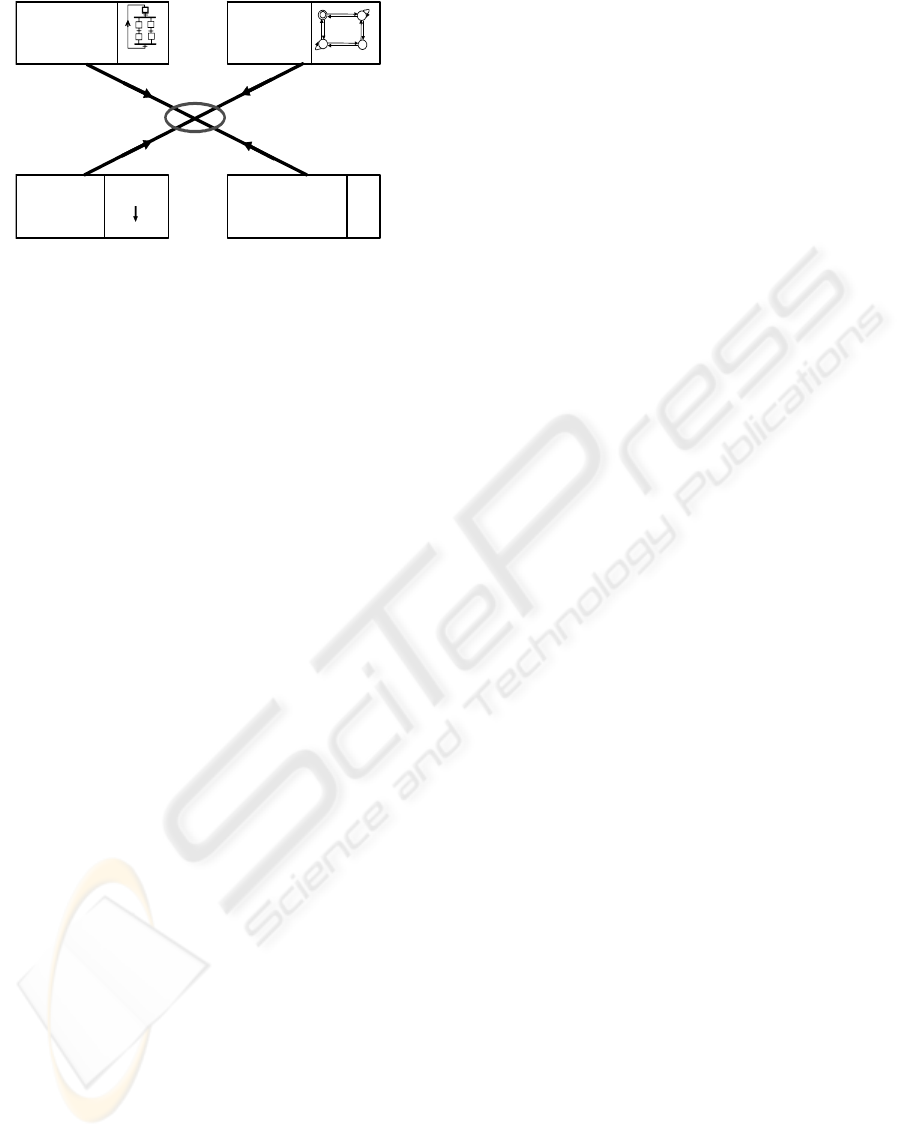

This approach uses different representation tools

(automata, rules, algebraic and mathematical

equations, ..) according to the available information.

The goal is to enrich the model in using all the

available information sources with a suitable

representation tool to be able to realize the

diagnosis. These sources are (see figure 1):

• functional information contained in the

process schedule conditions,

• structural information coming from the

process itself and the sensors-actuators

spatial distribution,

• symbolic information given by experts

and/or previous experience obtained by a

learning set of previous functioning,

• temporal information coming from the

space and temporal parameters of process

actuators and sensors.

For this approach, three models are defined: plant

control and diagnoser models.

5.1 Plant model

A plant model is divided into several components.

Each model G

i

and corresponding language L

i

describe the logical, untimed behaviour of the

monitored system. G = (M,

∑

c

) where M is a Moore

automaton: M = (

∑

, Q, Y,

δ

, h) :

∑

is the set of finite

events, Q is the set of states, Y is the output space,

δ

: ∑ x Q

→

Q is the state transition function.

δ

(

σ

, q)

gives the set of possible next states if

σ

occurs at q.

h: ∑ x Q

→

Y is the output function. H(

σ

, q) is the

observed output when

σ

occurs at q.

∑

c

⊆

∑

is the

set of controllable events.

∑

o

⊆

∑

is the set of

observable events where

∑

c

⊂

∑

o

. An automaton is

Functional

Information

Structural

Information

Symbolic

Information

Temporal

Information

Common Language

for dia

g

nosis

Co nt ro l

0

1

2

3

If - Then

Historic +

Expert

Plant

∆t?

Figure 1: Information sources

DETECTABILITY AND DIAGNOSABILITY OF DISCRETE EVENT SYSTEMS - Application on manufacturing

systems

151

used for each model. This automaton takes into

account all the observable events. The detailed

explication of the construction of this model can be

found in (Philippot, 2004), (Philippot, 05).

5.2 Control model

The controller model is constructed in using a

Sequential Function Charts. This letter reflects the

functional information corresponding to the schedule

conditions for all system components. The SFC is

chosen to model the controller because it is well

adapted for industrial applications especially

manufacturing systems.

5.3 Diagnoser model

The set of failures to be detected and isolated must

be defined as well as the type of these failures. Let

{}

∑

=

f

n

fff ,..,,

21

be the set of failures to be

detected and

{

}

n

fffN

SSSS ,..,,,

21

=Π denotes the

set of normal partition and the type of failures to be

isolated: sensor or actuator and which sensor or

actuator. Additionally, the nature of failure must be

defined: permanent or non-permanent.

Before constructing the diagnosers, a notion of

diagnosability must be defined to determine if the

system is diagnosable or not. A system is detectable

according to a set of observable events and a set of

partition iff each normal state can be distinguished

from all the failures:

)()(,

)()(

qhqhSqSq

SHSH

ANN

ANN

′

≠⇒∈

′

∀∈∀

⇒≠

(1)

Then, the system is diagnosable if we can

distinguish each partition of the set Π. This isolation

must be determined within a bounded number of

events and a bounded time:

)()(:, qhqhSqq

AN

′

≠∈

′

∀

(2)

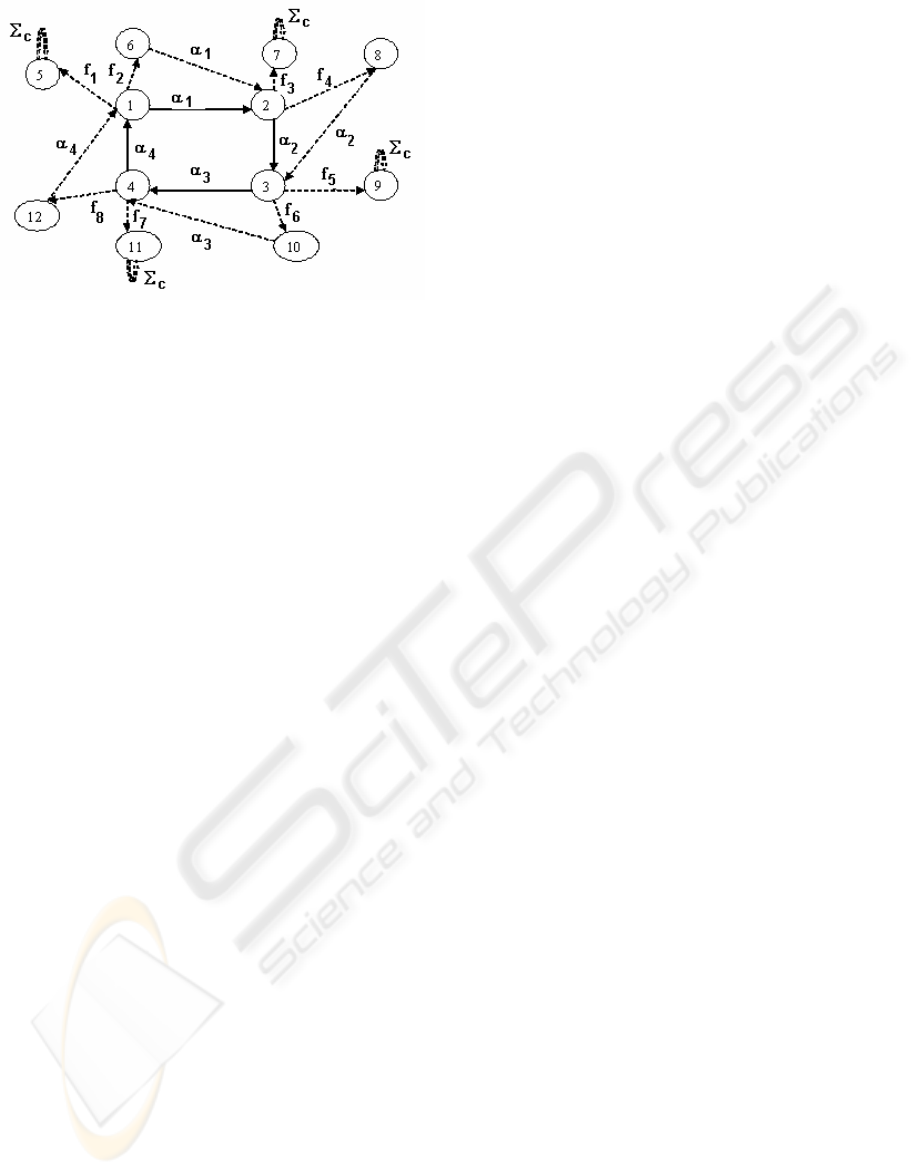

Let us take the following example (see figure 2) of a

process which has 4 normal states S

N

= {1, 2, 3, 4}

with the observable events

{}

4321

,,,

αααα

=Σ

o

.

The partition to be identified is

S

AN

= {5, 6, 7, 8, 9,10, 11, 12} which correspond to

the failure events

{}

∑

f

ffffffff

87654321

,,,,,,,.

The outputs of each state, thank for the sensors are:

H = {h

1

, h

2

, h

3

, h

4

, h

5

, h

6

, h

7

, h

8

, h

9

, h

10

, h

11

, h

12

}.

The figure 2 shows the functional model

corresponding to the product of the model plant with

the control model, in solid lines, and the diagnoser

model in dotted lines.

The failure events: f

1

, f

3

, f

5

and f

7

, indicate an

equipment failures, actuator, as stuck on or stuck off.

These events are non-observables and must be

detected either by an observable event which entails

a state with an output different from the estimated

one, in the case of stuck on, or by the fuzzy

functions of expected events occurrence instants in

the case of stuck off. The other failure events denote

the sensor failures. These events can be observable

or non-observable. In the case of observable ones,

the failure is detected at once without any delay.

This fact is important for the functioning of the SFC

in order to permit the evolution of the command.

Indeed our approach requires a validate sensor

values before permitting a new command. In the

case of non-observable events, as in the figure 2, the

failure must be detected in using only the sensors

outputs. In this case the non-observable failure

events correspond to a sensor stuck on, level 1, or

stuck off, level 0. The number of sensors must be

enough to distinguish all the states of normal and

abnormal states.

We can find that our approach combines event and

state based approaches in order to maximise the

diagnosability power with a minimum number of

sensors. In addition the time is integrated and

modelled with fuzzy intervals to enhance this

diagnosabilty power and to take into account the

imprecision and uncertainty of time occurrence

events.

Let us explain our algorithm to know if the system

represented by the figure 2 and for

{}

4321

,,,

αααα

=Σ

o

and S

AN

= {5, 6, 7, 8, 9, 10,

11, 12} is diagnosable. The first step of our

algorithm is to construct a matrix M(nxm) where n is

Figure 2: Functional and

diagnoser models

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

152

the number of observable events and m is the

number of normal states. Then, we determine the set

of events

∆

k

produced by the same sensor k. Let

suppose that for the sensor 1:

∆

1

= {α

1

, α

4

}and for

the sensor 2:

∆

2

={α

2

, α

3

}. For each event, we put 0

for all the states sources of this event as well as the

events produced by the same sensor. We put 1 for

the other colons. This matrix will be used to know if

a system is detectable or not and then if it is

diagnosable or not. Indeed, the event,

α

2

, indicates

that the state 1 was normal, but we need to wait the

event α

4

to know if the state 2 was normal. For the

example of the figure 2, we can find:

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

Σ

=

0110

1001

1001

0110

4321

4

3

2

1

α

α

α

α

No

S

M (3)

The application of (1) on (3) we can find that the

system is detectable iff:

1)..1:)..1:(( === mjniMORAnd

ij

(4)

If the system is detectable, the application of (3) on

(2) determines if the system is diagnosable :

1)..1:)..1:(( === nimjMXORAnd

j

i

(5)

We can find that the system of the figure 2 is

diagnosable. To calculate the delay to realize the

diagnosis, we use the following equation:

)..1:)..1(1( nimjMNOMaxDelay

ji

=== (6)

where NO1

i

is the number of ones in each line i. As

an example, to detect and localize a failure in the

state 2, failure f

4

, we need to wait that the event

α

4

takes place. Thus the delay is equal to 2 observable

events. In applying the same manner for the other

lines, we can find that the system is 2-diagnosable

for all the failures of the figure 2.

6 APPLICATION OF THE

PROPOSED METHOD

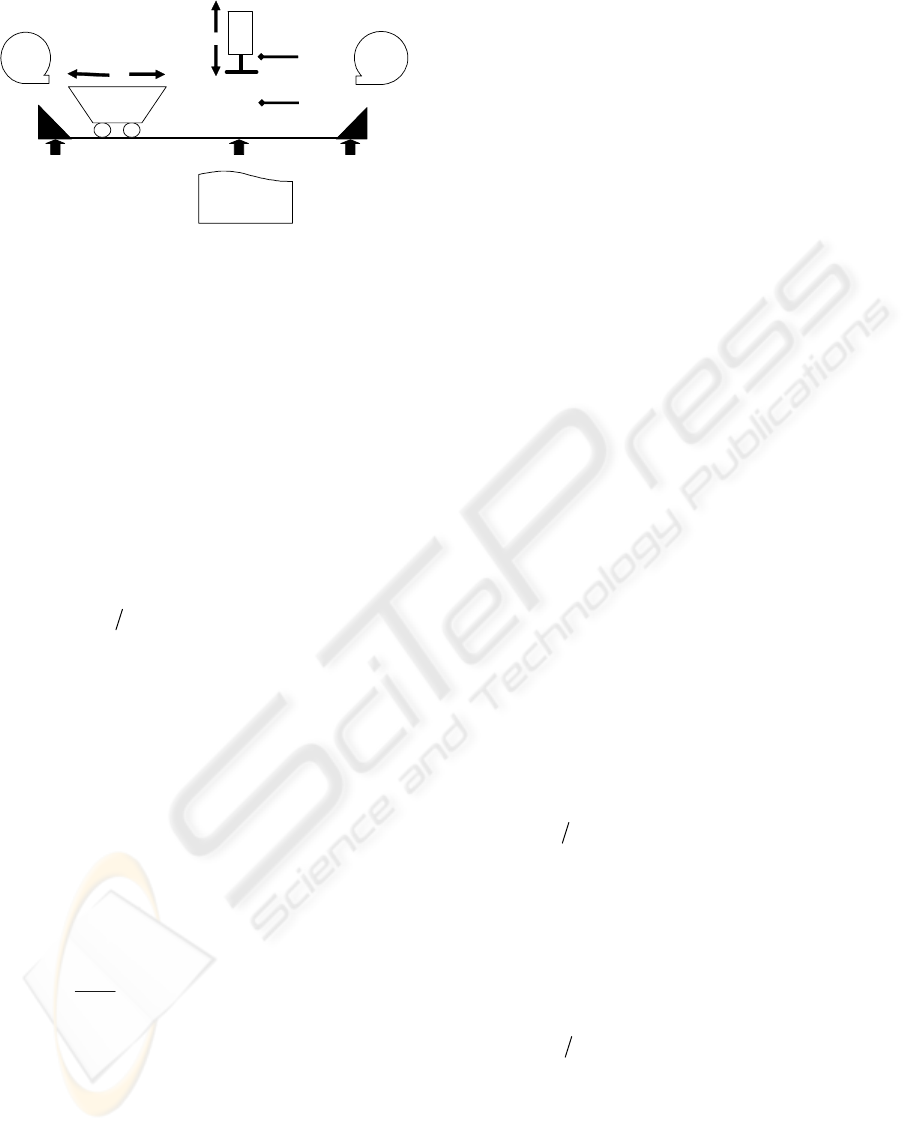

We will apply the notion of diagnosabilty to the

following example of a wagon with an electric

actuator with two senses of movements: left and

right, and a double effect cylinder: up and down.

Three sensors a, b and c are used to determine the

wagon position and two sensors fcr and fcs to

determine the cylinder position as it is illustrated in

figure 3. The schedule conditions are well defined

and the following hypotheses are verified:

•

There is one product (i.e. one wagon), each

actuator has its proper sensors and each

sensor is used by one actuator. The relax of

this hypothesis will be study in other

paper,

•

An accepted response time is defined for

each actuator as well as for the process by

the designer,

•

The wagon inertia is null.

The figure 4 shows the functional models of the

actuator (wagon) and the double effect cylinder

according to the SFC (Philippot, 2005).

The diagnosability matrix for the actuator, M

act

, and

the cylinder, M

cyl

, for the sensor failures are:

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

↑

↓

↑

↓

Σ

=

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

↑

↓

↑

↓

↑

↓

Σ

=

0110

1001

1001

0110

81141

01111110

11100111

11100111

10011001

10011001

011111

10

161281911741

cr

cs

cs

cr

No

cyl

No

act

f

f

f

f

S

M

a

c

c

b

b

a

S

M

We can find from M

act

, and M

cyl

, that the cylinder is

b

fcr

fcs

Up

Down

Right

Left

a c

Delivery point

Ore X

Ore Y

Figure 3: Exemple of application

DETECTABILITY AND DIAGNOSABILITY OF DISCRETE EVENT SYSTEMS - Application on manufacturing

systems

153

diagnosable and it is 2-diagnosable system and the

actuator (wagon) is diagnosable and it is 6-

diagnosable system. As an example, while being in

the state 11, figure 4, a failure has occurred in the

sensor a. We need to wait the occurrence of the

event b of the state 4 to detect and isolate this

failure.

7 CONCLUSION

In this paper, an algorithm to determine if a Discrete

Event System (DES) is diagnosable or not, for a set

of failures and according to a set of observable

events, is presented. This algorithm treats the case of

failures modelled by non-observable events for both

actuators and sensors. The failures modelled by

observable events can be also treated by this

algorithm and the detection and isolation will be

realized without any delay. This algorithm uses the

notion of events to determine if a permanent failure

has occurred. At the same time and to find a remedy

to the problem of initialization of the system and the

diagnoser, it uses the notion of state, to determine if

a failure has occurred before the initialization of the

diagnoser. This diagnosis is realized within a

bounded delay in basing on the sensors outputs and

the events sequences and their occurrence times.

This algorithm was tested successfully on an

example of manufacturing system. Firstly, this

algorithm has shown that the system is diagnosable

for the set of sensors and actuators failures and

according to the set of observable events. Then a

method to diagnose DES has applied, it has

diagnosed several simulated failures within a

bounded delay maximally equal to 6 events.

REFERENCES

Cassandras, C. G., Lafortune, S., 1999. Introduction to

Discrete Event Systems, Kluwer Academic Publisher.

Deepa Pandalai, N., Holloway, L. E., 2000. Template

Languages for Fault Monitoring of Timed Discrete

Event Processes, In IEEE Transactions On Automatic

Control 45( 5).

Garcia, H. E., Yoo, T. S., 2005. Model-based detection of

routing events in discrete flow networks, Automatica

41.

Holloway, L. E., Chand, S., 1994. Time templates for

discrete event fault monitoring in manufacturing

systems, In American Control Conf., Baltimore, MD.

Lin, F., 1994. Diagnosability of Discrete Event Systems

and its Applications, In Discrete Event Dynamic

Systems4, Kluwer Academic Publishers, Boston, USA.

Perrow, C., 1984. Normal Accidents:Living with High Risk

Technologies, Basic Books, Inc., New York.

Philippot, A., Sayed Mouchaweh, M., Carré-Ménétrier,

V., 2005. Multi-models approach for the diagnosis of

Discrete Events Systems, In IMACS’05, International

conference on Modelling, Analyse and Control of

Dynamic Systems, Paris-France.

Philippot, A., Tajer, A., Gellot, F., Carre-Ménétrier, V.,

2004. Méthodologie de modélisation dans le cadre de

la synthèse formelle des SED. Conférence

Internationale Francophone d’Automatique, Douz,

Tunisie.

Ramadge, P., Wonham, W., 1987. Supervisory control of

a class of discrete event processes, In SIAM J. Control

Optim. 25(1).

Sampath, M., Sungupta, R., Lafortune, S., Sinnamohideen,

K., Teneketzis, D., 1994. Diagnosability of discrete

event systems, In 11

th

Int. Conf. Analysis Optimization

of Systems: Discrete Event Systems, Sophia-Antipolis,

France.

Su, R., 2004. Distributed Diagnosis for Discrete-Event

System, Thesis of PhD, University of Toronto, Canada.

Tripakis S., 2001; Fault Diagnosis for Timed Automata,

VERIMAG (www-verimag.imag.fr).

Wang, Y., 2000. Supervisory Control of Boolean Discrete-

Event Systems, Thesis of Master of Applied Sciences,

University of Toronto, Canada.

Zad, S. H., Kwong, R. H., Wonham, W. M., 2003. Fault

Diagnosis in Discrete Event Systems: Framework and

model reduction, IEEE Transactions On Automatic

Control 48( 7).

Zad, S. H., Kwong, R. H., Wonham, W. M., 1998. Fault

diagnosis in discrete-event systems. In CDC’98, IEEE

Conference on Decision and Control, Tampa, Florida,

USA.

Figure 4: Functional models of the wagon and the

cylinder for the application example

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

154