THERMAL SPRAYING ROBOT KINEMATICS AND LASER

PATTERN CONTROL

D. Breen, E. Coyle and D.M.Kennedy

Faculty of Engineering, Dublin Institute of Technology, Dublin, Ireland

Keywords: Thermal spraying, kinematics, vision analysis, laser pattern control.

Abstract: The thermal spraying surface engineering industry relies on manual spraying and standard pre-programmed

robotic systems. This research presents the completed geometric forward and inverse kinematics solution

for a non standard articulated robotic manipulator which includes continuous 360

0

axis rotation for waist,

shoulder and elbow joints with a commercially available joint for tilt and pitch. The research also details the

use of Polytetrafluoroethylene (PTFE) electroless nickel slip rings and brushes for providing delivery of

power and data through the continuous rotation joints. The automatic analysis of distance and orientation

measurement via a pattern producing laser and camera system is being researched for suitability in the

thermal spraying process for automatic feedback and control of the robotic arm manipulator. The competed

technical and simulation design will provide for the automatic application of advanced surface coatings to

enhance wear, low friction and corrosion resistance properties to substrates via a thermal spraying process.

1 THERMAL SPRAYING

SURFACE COATING

1.1 Introduction

Surface coating via thermal spraying involves the

application of wear and corrosion resistant coatings

to various substrates and has been traditionally

carried out in the aerospace, power generation and

petrochemical industries (Air Products). However

improvements in the technology has resulted in

opening up of additional markets, in particular in the

biomedical and electronic coating industries. It is

further possible today to apply coatings to polymer-

based materials (England). Thermal spraying is a

generic term for a range of thermal spraying

technologies. There are four systems. These consist

of High Velocity Oxyfuel Spraying (HVOF), Plasma

spraying, Arc spraying and Flame spraying. Flame

spraying for example is used in the application of

corrosion resistance aluminium to off-shore oilrigs

(Air Products,

Richard Halldern) Another example

of surface coating is biocompatible hydroxylapatite

coating of prostheses, which are made of materials

such as titanium. This is achieved with the HVOF

system.

1.2 Powder Flame Spraying

The majority of components are sprayed manually or

via standard pre-programmed robot manipulators

and the development of an autonomous robot arm to

carry out the thermal spraying process will reduce

costs and health and safety risks.

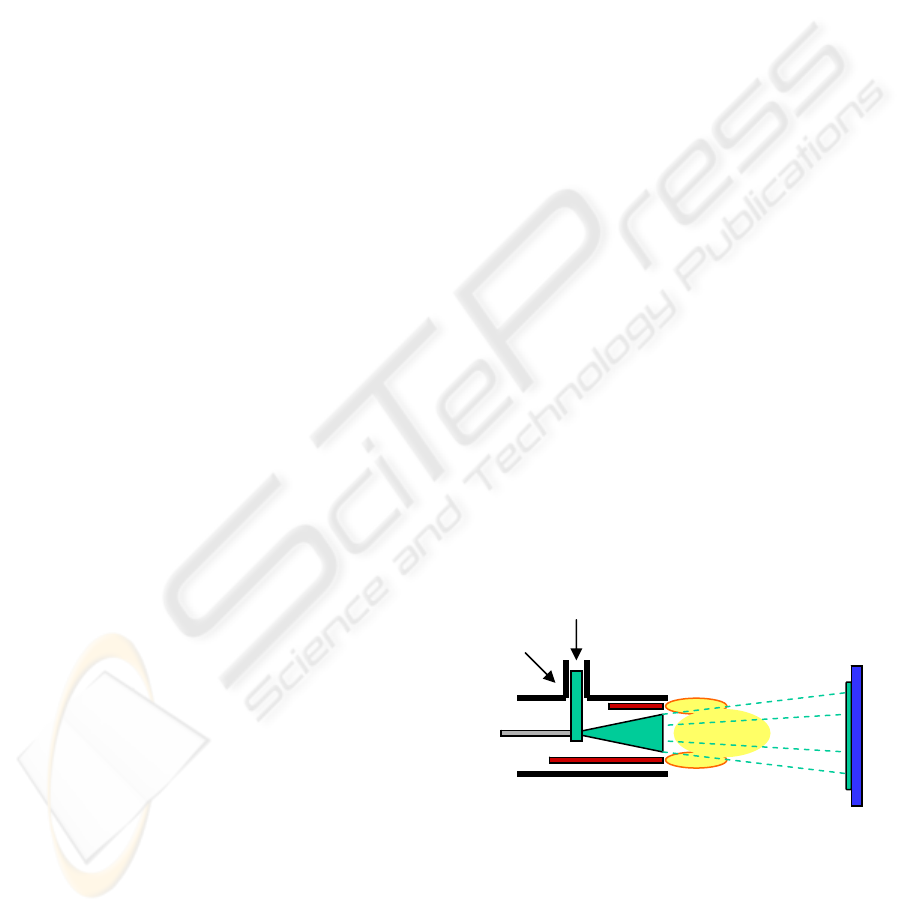

A schematic of the powder thermal-spraying

process is shown in Figure 1.

Coating

Powder

Flame

Spraying

Head

Burning

Gas

Sprayed

Material

Gas

Spray

Stream

Fuel

Figure 1: Powder thermal-spraying process

Prepared

Substrate

The coating process must occur in a very

precise manor to ensure quality control. Following

surface preparation, there can be up to three main

stages in applying a metallic coating to a substrate

and control of the position of the torch at each stage

is an important design and control parameter.

411

Breen D., Coyle E. and M. Kennedy D. (2005).

THERMAL SPRAYING ROBOT KINEMATICS AND LASER PATTERN CONTROL.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 411-414

DOI: 10.5220/0001172504110414

Copyright

c

SciTePress

The three stages are pre-heating the substrate,

spraying the substrate with the coating material and

finally fusing the coating to the substrate. Other

processes only require pre treatment by shot

blasting. The coating and fusion process takes place

in a single step such as plasma or HVOF spraying.

2 ROBOT ARM KINEMATICS

2.1 Model of a five-axis articulated

robot arm with 360

0

joints.

While researching the type of robot manipulator

applicable to thermal spraying it became clear the

articulated type was preferable. It was also decided

to include the novel feature of continuous 360

0

rotation for the waist, shoulder and elbow joints

which provides advantages of maximising

workspace and improved flexibility. A 5 DOF

manipulator will also be specified, as spraying does

not require a roll axis thus reducing the cost of

additional joint actuator and control equipment.

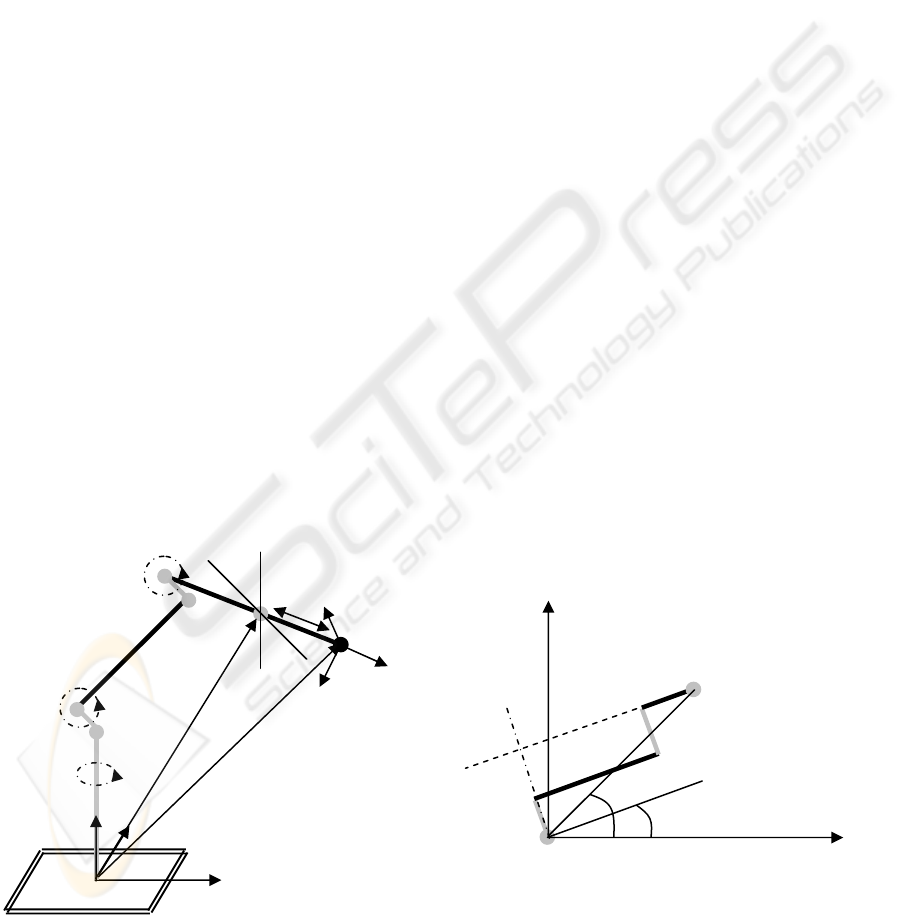

The model of a five-axis articulated robot arm

design, which has continuous 360

0

rotation waist, θ

1

shoulder, θ

2

and elbow, θ

3

joints is shown in Figure

2. A commercially available Omni-Wrist unit will

provide the pitch and yaw axis joints available from

Ross-Himes Designs. [Joints in grey, links in black].

Figure 2: Five axis robot arm model

2.2 Forward Kinematics

Using the Denavit and Hartenberg (Niku, 2000 et

al.) method and standard notation for developing the

robots forward kinematic arm matrix,

R

T

H

produces a

set of highly coupled, non linear equations in θ

1

, θ

2

,

θ

3

, θ

4,

and θ

5

for this particular robot design. The

Matlab

TM

symbolic toolbox was used to produce the

equations. To test these equations a model of the

robot arm was made using Lego

TM

and sample

solutions were tested successfully against the

physical model. As an example, using the vector of

angles in degrees [ -170 50 –45 20 –30 ] produces

the position and orientation matrix

n o a p

-0.42 -0.30 -0.86 3.46

-0.07 -0.93 0.36 -7.45

-0.91 0.21 0.37 24.56

0 0 0 1.00

2.3 Inverse Kinematics

To solve the inverse kinematics for this robot arm

with 360

0

continuous rotation joints the techniques

detailed in Sciavicco and Siciliano, 2000 and Niku,

2001 have been combined and modified as

necessary. The steps necessary to solve the inverse

kinematics are now detailed.

Step 1: From Figure 2 the wrist position vector is

given by p

w

= p – a

5

a.

Step 2: The second step is to determine the waist

angle θ

1

. This can be obtained by considering the

plan view of a general position angle θ

1

shown in

Figure 3.

Figure 3: Plan view at angle θ

1

The angle |AC| makes with the x

0

axis can be

determined from θ

AC

= Atan2(p

wy

,p

wx

). The length

|AB| = d

2

+ d

3

(fixed quantities) therefore ∠BAC can

be determined from trigonometry. The angle |AB|

p

wx

, p

wy

x

0

y

0

A

C

B

θ

1

θ

AC

Base

Z

0

y

0

x

0

Pitch

axis θ

4

Yaw

axis θ

5

Elbow, θ

3

o

a

n

Shoulder,

θ

2

Waist, θ

1

p

p

w

a5

ICINCO 2005 - ROBOTICS AND AUTOMATION

412

makes with the x

0

axis is ∠BAC + θ

AC

therefore θ

1

=

∠BAC + θ

AC

– 90 degrees. The angle θ

1

for any

point on the circle scribed by |AC| can be obtained

with this technique as can the angle on any plan

view circle within the robot arms workspace.

Step 3: Once θ

1

is determined the solution for angles

θ

2

and θ

3

become solutions for a simple two axis

robot arm in two dimensions as long as the p

wx

component is the length |BC| shown in Figure 3.

Step 4: Now that the waist, shoulder and elbow joint

angles have been identified a change of approach

will provide solutions for the pitch and tilt angles.

The forward arm matrix is made up of the

multiplication of six translation and rotation

matrices

R

T

H

= A

1

A

2

A

3

A

4

A

5

A

6

The product A

1

A

2

A

3

and its inverse can now be

calculated, therefore multiplying the given position

and orientation matrix by the inverse of A

1

A

2

A

3

will

provide a pan_tilt matrix, which is equal to A

4

A

5

A

6

.

A

6

is a constant known rotation and inspection of the

coefficients of A

4

A

5

A

6

provides solution equations

for θ

4

and θ

5

which are:

θ

4

= Atan2(pan_tilt(1,1), -1*pan_tilt(2,1))

θ

5

= Atan2(-1*pan_tilt(3,3),-1*pan_tilt(3,2)).

The solution outlined does not make use of the

360

0

continuous rotation capability of shoulder and

elbow joints as solutions will always place these

angles in the right half circle whose centre line is

along |AB| and containing the point C. However if

the shoulder and elbow joints make angles which

move point C into the opposite half of the circle then

a simple change will produce the alternative

solution; θ

1

= θ

AC

- ∠BAC – 90. The p

wx

component will be negative for this condition.

In a practical application requiring random

movement to different locations both solutions could

be tested and the one requiring the shorter travel

distance would be executed. The solution complying

with pitch and tilt limits also requires testing, as

does the elbow up and down options.

A Matlab

TM

function inv_axis_5.m has

been written which implements each of the steps

outlined for the first solution. However data to test

the code is difficult to generate. The data must be

within the operational workspace of the robot

manipulator and not cause singularities. Most robot

manipulators are pre-programmed and components

to be sprayed must be placed in exact location and

orientation, which is very time consuming. This

highlights one of the key areas for more advanced

research, that is the generation of trajectory data

using information from 3D transducers for the robot

to operate autonomously and to carry out requested

random movements efficiently. To test the code the

forward kinematic function axis_5.m was used to

generate position and orientation data as input data

to the inverse kinematics function.

Running the function using the previous

numerical example in section 2.2 where the input

angles are [ -170 50 –45 20 –30 ] provides solution

angles which are different [-170 20.7 45 -40.7 –30 ]

but with identical input and output position and

orientation arm matrices, highlighting the different

solutions outlined. The tilt and pan angles are within

range.

A significant advantage of continuous rotation

360

0

joints is the travel distance/time required. As an

example if the robot arm is in the home position and

a call is made for the shoulder joint to rotate 260

0

the

robot can move in the opposite direction by –100

0

in

a shorter time. If the same time is acceptable the

robot can move slower with less vibration. Safety is

a key issue and must be taken into consideration

with 360

0

continuous rotation calls as the torch may

hit the vertical joint.

Determining closed form inverse equations

produces a more computer efficient system than

alternative methods, which use the forward

kinematic equations, and iterative methods such as

Gaussian elimination (Niku).

2.4 Joint cabling

Joint cabling research for power and data is pointing

to the use of PTFE electroless nickel slip rings and

brushes. PTFE electroles nickel has the advantages

of low coefficient of friction, low wear and being a

good conductor. A prototype slip ring and brushes

test rig using electroless nickel coated copper

samples was set up and zero resistance was recorded

on the lowest resistance setting (200 Ω) of a

standard digital multimeter. Inclined plane tests

indicate a coefficient of friction for electroless nickel

on electroless nickel, which is 30% better than

copper on copper. PTFE electroless nickel should

provide better results than this. The slip ring and

brushes was videoed with the video signal passing

through the slip rings without any appreciable

reduction in quality.

3 LASER PATTERN CONTROL

Research is now concentrating on mapping

autonomously, complex 3D surfaces in the harsh

THERMAL SPRAYING ROBOT KINEMATICS AND LASER PATTERN CONTROL

413

environment of thermal spraying, for autonomous

robot manipulator control. This will reduce pre-

programming and set up times significantly.

Initial depth measurement tests have been

carried out on the steel plate shown in Figure 4 with

a web camera and presentation laser. Image

processing and analysis has been carried out using

NeatVision (Whelan and Molloy, 2001), an open

source Java based image processing software

package and Matlab

TM

Image Processing Toolbox.

Figure 5 shows two white dots clearly separated,

correlating to the raising of the plate.

Further work on applying this technique and

measurement resolution obtainable in the harsh

environment of thermal spraying applications shown

in Figure 6 is ongoing.

Figure 4: Steel plate Figure 5: Depth

Figure 6: Harsh Thermal Spraying environment

Further research will also consider the use of

patterns produced by a laser when passed through a

diffraction grating for 3D surface mapping. As an

example the patterns shown in Figures 7 and 8,

provide information on depth (size of circle), flat

surface angle (elongation of circle) and sharp edges

(discontinuity of the circle).

Figure 7: Circle and Elongation

Figure 8: Discontinuity

Applying image subtraction tresholding erosion

dilation and thinning provides black and white

outline images of the circle, oval and semicircle for

further analysis. Image processing values were

chosen manually and the intended aim of the

research is for these values to be determined

automatically in the thermal spraying environment.

4 CONCLUSION

This paper has presented the forward and inverse

kinematics solution for an unusual 5-axis articulated

robot manipulator with 360

0

continuous rotation of

the waist, shoulder and elbow joints, and providing

an efficient method for determine joint angles from

given tool tip position and orientation. The

advantages of such a manipulator are also presented.

The paper has outlined the progress on developing

an efficient slip rings and brushes solution for

cabling through the continuous rotation joints.

The paper has also highlighted techniques being

pursued, which will be researched for their

effectiveness in the harsh environment of thermal

spraying. Solutions will transform time-consuming

pre-programmed thermal spraying operations to an

efficient autonomous operation.

REFERENCES

Air Products,. “Thermal Spraying”

http://www.airproducts.com/

England, G.,. “Thermal Spray Coatings on Carbon an

Glass Fiber Reinforced Polymers”

http://www.gordonengland.co.uk/

Matlab

TM

. http://www.mathworks.com

Niku, Saeed B., 2001. Introduction to Robotics Analysis,

Systems, Applications, Prentice Hall. New Jersey 1

st

edition.

Richard Halldern “Flame Spraying” TWI (2001)

http://www.twi.co.uk/j32k/protected/band_3/ksrdh001

.html

Ross-Himes Designs,.Omni-wrist

http://www.anthrobot.com/omni/detail.html

Sciavicco Lorenzo, Siciliano Bruno, 2000. Modeling and

Control of Robot Manipulators. Springer London 2

nd

edition.

Whelan, Paul F., Molloy, Derek, 2001. Machine Vision

Algorithms in Java Techniques and Implementation,

Springer. London 1

st

edition.

ICINCO 2005 - ROBOTICS AND AUTOMATION

414