HIGH TEMPERATURE DENSITY MEASUREMENT CELL WITH

A PCMCIA-INTERFACE

Bernd Eichberger

Graz University of Technology, Department of Electronics, Inffeldgasse 12, 8010 Graz, Austria

Anton Scheibelmasser

CAMPUS 02, University of Applied Sciences, Automation Technology, Körblergasse 111, 8021 Graz, Austria

Keywords: Density-Measurement, PCMCIA, File-Mapped I/O.

Abstract: One of the most precise and reliable measurement methods for density measurement of liquids and gases

depends on the principles of a mechanical oscillator. With this method the density is determined by

measuring the natural frequency of the oscillator. Measurement devices using this method can be

categorized in two groups. The first type incorporates the mechanical oscillator in the housing of the device

and is mainly used in laboratories. The second type of measurement devices could be defined as evaluation

units, because the sensor e.g. mechanical oscillator is external and only connected by means of electrical

connections. These types are used in the field of process data control or data acquisition. The reason for

separating the sensor from the evaluation unit lies in the fact that such external cells are used on remote

locations in the process or the sensor is exposed to extreme physical conditions (e.g. high pressure, high

temperatures). The first part of this article gives an overview about the functionality of such a high

temperature measurement cell. The second part of this paper is intended to introduce a sophisticated

PCMCIA interface which acts as an interface between the external density measurement cell and several

hosts like PCs, PDAs or modern density measurement devices.

1 INTRODUCTION

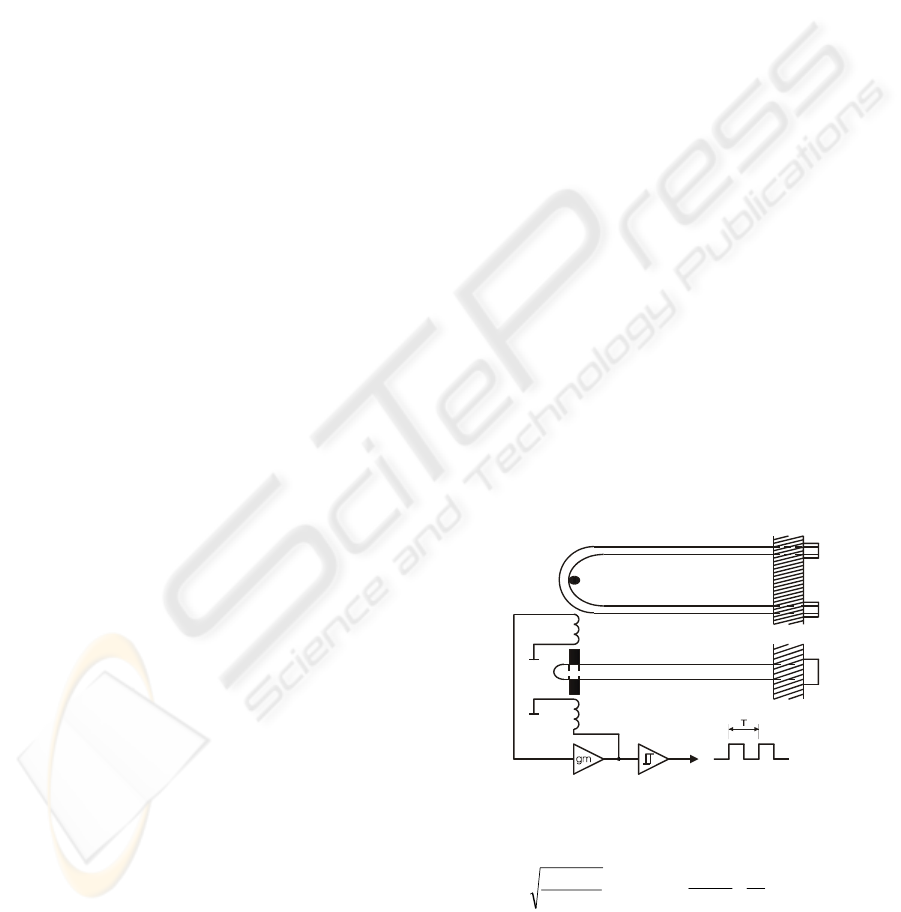

The sensor principle used in this application

converts the density of a liquid into the period of an

oscillating mechanical resonator. A U-shaped tube,

whose open ends are mechanically mounted on a

solid base plate, is filled with the liquid. For exciting

this mechanical fork oscillator a periodic excitation

force is applied, which is in opposite phase to the

speed of movement of the tubes, thus compensating

the mechanical damping force. The electrical

excitation system consists of a speed sensor, a

limiting amplifier and an actuator for mechanical

feedback. (see Figure 1)

Both the mass M of the tube and the mass

ρ

.V of

the liquid inside as well as the spring constant c of

the tube determine the resonant frequency f and its

inverse, the period T, according to equation 1. Re-

arranging this relationship results in equation 2,

which is the basis for the subsequent numerical

calculations.

Figure 1: Mechanical fork oscillator (Leopold, Eichberger,

1993)

Equation 1: Period of the fork, Equation 2: Density

The frequency of the mechanical oscillator, which is

output as a binary voltage or current signal, is

measured using a high resolution counter and a

c

VM

T

.

2

ρ

π

+

=

c

M

V

T

−=

..4

2

2

π

ρ

316

Eichberger B. and Scheibelmasser A. (2005).

HIGH TEMPERATURE DENSITY MEASUREMENT CELL WITH A PCMCIA-INTERFACE.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 316-319

DOI: 10.5220/0001158003160319

Copyright

c

SciTePress

precise and stable reference oscillator. As standard

PCs or PDAs do not have the capability to handle

such a signal directly, considerations about how to

incorporate such an interface have to be taken (see

chapter 3).

2 THE HIGH TEMPERATURE

MEASUREMENT CELL

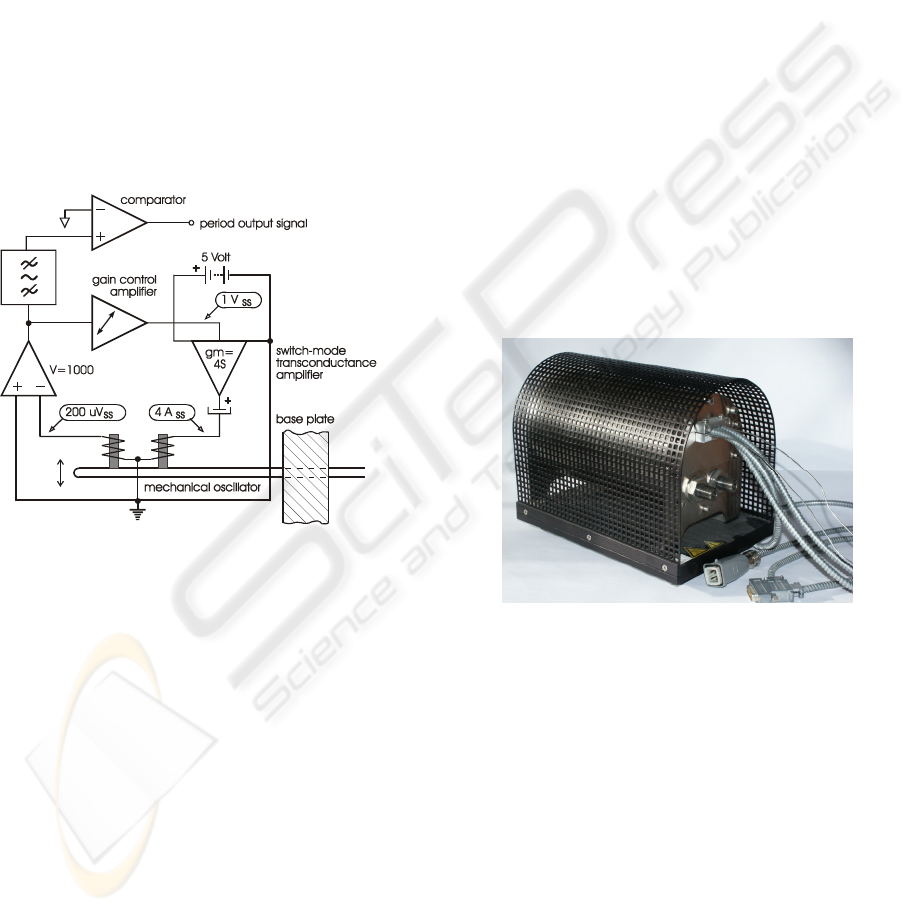

Density measurement at temperatures up to 400 °C

significantly increases the useful range of

applications, for example in the fields of material

research or the petroleum industry. Normally, the

mechanical resonator is mounted inside the housing

of the instrument, together with its electrical

interfaces and a microprocessor control unit.

Figure 2: Excitation amplifier (Leopold, Eichberger, 1993)

Due to the demanding ambient conditions an

external measurement cell design was implemented.

The system can operate as a stand-alone unit or be

placed in a temperature-controlled oven. It consists

of a mechanical fork oscillator, PT100 temperature

sensors and an optional set of electrical heaters. The

electrodynamic excitation uses two AlNiCo

magnets, mounted on the moving end of the fork

resonator, which dip into pick-up and drive coils.

These coils are made of five turns of steel wire and

attached to a ceramic insulator. An interface box,

located nearby and operating at normal ambient

temperatures, performs the basic hardware interface

functions. The period of the mechanical resonator,

temperature data and the power control of the

heaters are transmitted or received in a digitally

encoded format. Figure 3 gives a functional

overview of the excitation system. Four amps of

drive current deliver only 200 micro volts from the

feedback coil, causing stringent requirements on the

analogue signal processing circuitry. The amplitude

of the mechanical resonator is regulated by a gain

controlled amplifier. A band-pass filter and a

comparator provide a precise period output signal.

3 EXTERNAL CELL INTERFACE

External cells most often use a frequency output

voltage or current loop (0-18mA) to enable

evaluation units to determine the density. In contrast

to Lab-Density-Meters, were the frequency signal

from the internal cell is directly evaluated by a

microcontroller, external cells require an electronic

interface to convert the analogue signal in digital

values. Such an interface consists of a power supply,

an additional microcontroller, a separate housing and

communication lines for transmitting a standardized

protocol. Figure 4 shows the high temperature cell in

its housing. The shielded tubes contain the electrical

connections for the excitation system, two PT100

temperature sensors and AC-powered heaters.

Figure 3: External high temperature density measurement

cell (Anton Paar GmbH, 2005)

In order to achieve an economical solution,

efforts were made to reduce the complexity of the

system and to lower the components count. Finally,

the best compromise was achieved by using a

PCMCIA interface.

3.1 PCMCIA Interface

PC Cards (PCMCIA, 1998), were the first

generation of credit card sized cards, introduced in

the late 1980s. The cards provide 68 pins for

electrical connections. In general, PC-Cards are

either available as memory cards in several

HIGH TEMPERATURE DENSITY MEASUREMENT CELL WITH A PCMCIA-INTERFACE

317

technologies (ROM, RAM, FLASH), or as I/O cards

(ATA disk-drives, network/modem-, or interface-

cards). Depending on the card’s thickness, PC-Cards

are available in 3 different mechanical types ( Type:

I, II, II) in the range from 3.3, 5 to 10.5 mm.

Independent from the card’s technology, the

characteristics of the card are described in a special

memory area on the card, called CIS (card

information structure).

Figure 4: PCMCIA I/O card (Kontron,2005)

Typically, cards only contain Flash devices and a

rudimentary control circuit. As the card is powered

by the host, no separate power supply is needed. The

card kits (housing) are available from different

vendors with the necessary plugs and shielded

cables. Card kits provide a low cost, high quality

housing for electronic circuits. Because of the long

availability on the market, most of the laptops and

PDA (personal digital assistant) are equipped with a

PC-Card slot. Even modern laboratory density

meters provide the user with such slots.

3.2 Cards Control Circuit

The main task of the card’s control circuit is the

precise determination of the oscillator frequency of

the mechanical fork resonator. Therefore the signal

has to be converted into a binary logic signal which

is compared with a precise high frequency crystal

time base The digital output of this circuit (gated

timer without termination error) has to be stored in

data registers which are accessible from the host

with the standardized PCMCIA interface.

The realisation of the digital circuitry using a CPLD-

technology (complex programmable logic devices)

offers a lot of advantages. CPLDs offer the user the

flexibility of programming them in the field (ISP) by

means of a JTAG-interface. Low power

consumption, less PCB (printed circuit board) area,

high integration and high level programming support

(VHDL, ABEL) are good arguments for the use of

these devices.

Figure 5: Block diagram of the PC-Card interface

3.3 PLD Logic

The control logic (Röhrer,1989) implemented in the

CPLD fulfils the following requirements:

− Counting of the period signal based on a stable

and high precision reference crystal oscillator

− Storing of counter results after a selectable gate

time (1, 2, 4, 8 sec.) with an additional identifier

− Consecutive measurements, no termination error

− Implementation of data register for the

intermediate results, accessible from the host via

the PCMCIA interface

− Implementation of a command register (average

time register)

− Generation of the chip select signals for

additional Flash storage memory on the card.

For the implementation of these requirements, HDL-

Tools (hardware description language) capable for

many languages (VHDL, ABEL, VERILOG) are

available from different vendors. Typically, the

required tools are provided by the vendor of the

CPLD.

3.4 PC-Card Structure

The logic circuits in the CPLD and the additional

Flash Storage memory on the PC-Card are

implemented according to the following memory

map:

PERIOD

SIGNAL

PCMCIA

SIGNALS

CURRENT TO DIGITAL LOGIC CONVERTER

PCMCIA INTERFACE

CRYSTAL OSZILLATORJTAG INTERFACE

JTAG

CPLD

FLASH STORAGE

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

318

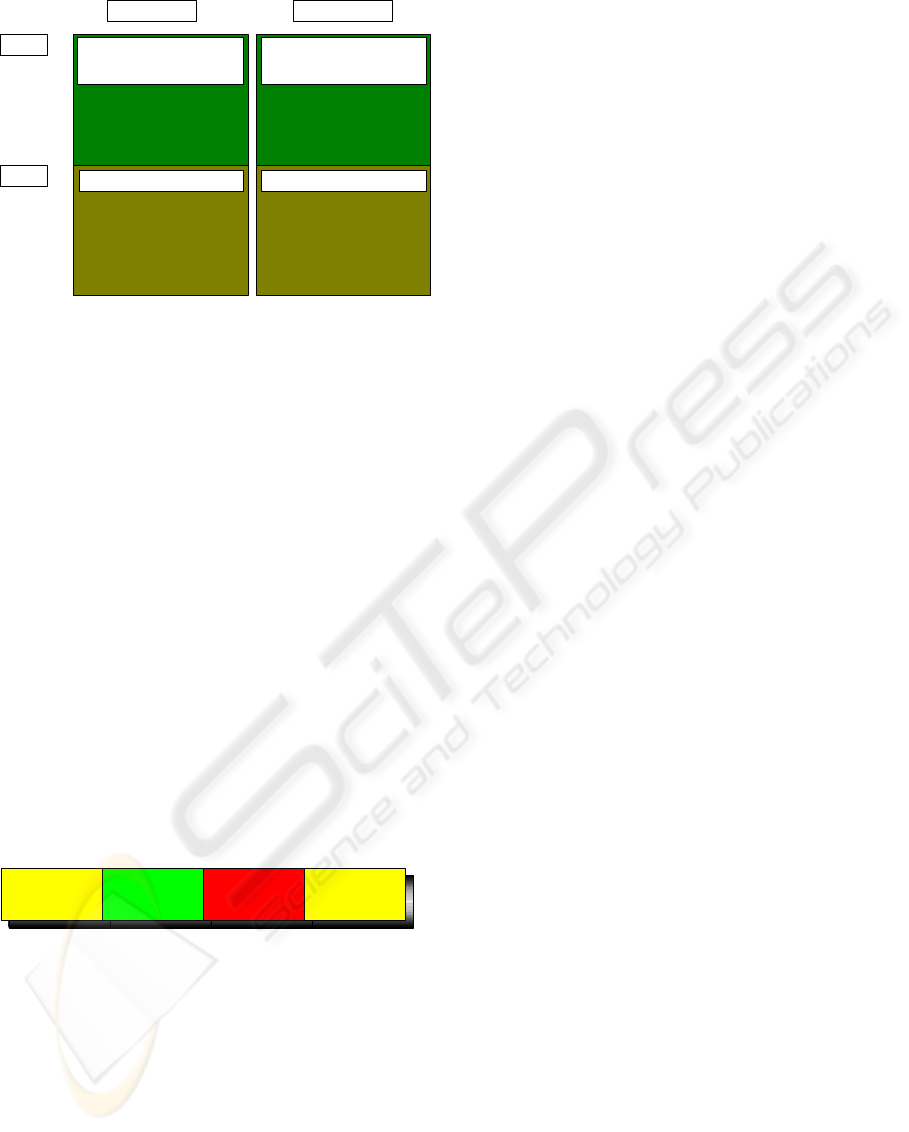

Figure 6: Memory mapped I/O card

As shown in Figure 6, the PC-Card is designed as a

memory card with an address range of 64 kByte In

the lower part of this range, the built-in flash

memory is selected and provides two types of

information. The first, called Attribute Memory,

enables the PC-Card to be used in combination with

an operation system. A special data structure (CIS,

Card Information Structure]) located at the address:

0x0000 describes the card’s characteristics in a

standardized way (PCMCIA, 1989). One of the

characteristics of this PC-Card is the command

register at the location: 0x80000, which is used to

set the gate time of the period measurement. The

second kind of information is placed in the common

memory address area. An optional file system

located at the address which is defined in the

attribute memory can be used to store additional

information (see chapter 4.5). Above the address:

0x80000, an eight-byte data structure stores the

measurement results. Details of the structure are

shown in Figure 7.

Figure 7: Data structure of the period measurement

Every time a measurement cycle is completed, the

identifier is automatically incremented. The result of

the measurement is calculated by dividing the period

counter by the clock counter. Synchronization of the

reading and the measurement logic is done by

evaluation of both identifiers. Only if these

identifiers are equal, the data structure is accepted to

be consistent.

3.5 Software Interface

A PC-Memory-Card type was developed for this

application. Such cards do not require specialized

software drivers, because they are detected correctly

by modern operating systems. Access to the memory

mapped data registers is implemented using a file-

mapped-I/O method. A special file image is placed

in the Flash-Storage with a total length of 0x80000

Bytes. In this image the last file in the directory

structure is not a real, but a virtual data file. Within

the FAT (File Allocation Table) the content of this

virtual file is linked to the data registers in the CPLD

outside the Flash-Storage area. The software running

at the host computer can now easily access the

measurement data by issuing a read command to this

file. Calibration data and parameters as well as

customer specific algorithms are stored at the host.

The application program uses this additional

information to calculate the density from the

measurement data.

The remaining files on this image are real data

files. They hold the necessary information

concerning the PC-Card (documentation, evaluation

program etc.).

4 CONCLUSION

The application of the described PC-Card-Interface

shows excellent results in the field and offers for the

evaluation of external density cells a convenient

solution which is capable to interact with PCs,

PDAs, modern laboratory density meters and

evaluation units (Anton Paar GmbH, 2005). The PC-

Cards CIS informs the host about the file system and

is therefore mapped as an exchangeable volume

without the need of special drivers. Due to the file-

mapped I/O structure, only simple file access is

required to get the measurement data.

REFERENCES

Leopold, H., Eichberger B., 1993, Ein Sensor für die

Dichte heißer Flüssigkeiten, Tagung Mikroelektronik,

Berichte der Informationstagung ME 93, Pages 102-

106, VDE-Verlag, Wien

Röhrer, R., 1989, Proceedings on the 2

nd

intensive course

on : „Programmable Logic Device“, pp.91-132, Cluj-

Napoca, Romania

Anton Paar GmbH, 2005, www.anton-paar.at

Kontron, 2005, www.kontron.com

PCMCIA, 1998, Personal Computer Memory Card

International Association, www.pcmcia.org

FLASH FLASH

CPLD CPLD

COMMON MEMORY

ATTRIBUT MEMORY

0x80000

0x00000

optional FILE Structure

optional CIS (Card Information

Structure)

DATA REGISTER COMMAND REGISTER

Identifier_1

(1 Byte)

Period Counter

(2 Byte)

Clock Counter

(4 Byte)

Identifier_2

(1 Byte)

HIGH TEMPERATURE DENSITY MEASUREMENT CELL WITH A PCMCIA-INTERFACE

319